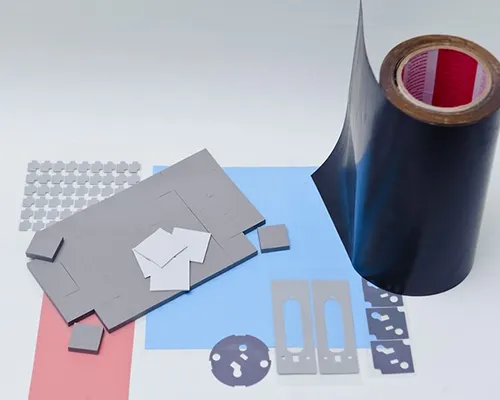

Thermal Interface Material

Walmate thermal is specialize in custom thermal interface materials, catering to heat dissipation needs of various electronic devices. These materials conduct heat efficiently, reduce device temperature differences, and enhance operational stability.

What is a thermal interface material?

Thermal interface materials are made by crushing various high thermal conductivity materials into powder, then mixing them with glue in a certain proportion, and finally forming them into sheets or substances with different viscosities under high pressure. This substance is typically used to fill the connection between electronic components and heat sinks, thereby reducing the gaps formed between the heat sink and the components, which would otherwise create significant thermal resistance. When filled with this interface material, a large amount of heat can be conducted to the heat sink, thus lowering the temperature of the entire chip.

Walmate Thermal launched thermal interface material products that were in line with the leading technology at the time, thereby helping our customers achieve high-performance operation of their products. We create advanced protection electronic components and system solutions, collaborate with some of the world’s leading technology brand companies to research, and rely on the continuous improvement and technological breakthroughs of our products to achieve more suitable performance and reliability, faster compliance, and faster application in many electronic heat dissipation fields.We solve design problems through innovative products, taking into account technical details such as thermal power consumption, heat dissipation methods, structural gap design and tolerances, insulation requirements, assembly pressure, etc. of electronic components. Our R&D engineers will combine these practical application scenarios to provide our valuable customers with suitable material selection and solutions.

We have more than a decade of producing heat sinks and liquid cold plates, we have encountered diverse needs from different customers for such thermal interface materials. Backed by our extensive practical experience and a wealth of R&D data, we have collaborated with downstream suppliers to develop a series of high thermal conductivity interface materials to meet customer needs. These materials have passed multiple experimental tests and can perform well under different working conditions and temperature conditions, truly providing customers with system-level heat dissipation solutions.A good heat dissipation system not only requires suitable thermal interface materials, but also suitable heat sink and liquid cooling plate to be used in combination, so as to have a perfect heat dissipation solution.

Thermal Pad

Based on the different power requirements of customers, produce thermal pads of different thicknesses for filling the gaps between heat sink components and chips to increase the overall heat transfer capacity of the system. The unique combination of thermal conductivity and flexibility reduces mechanical stress while maintaining thermal performance. Walmate Thermal has a wide range of gap pad product lines, including various properties, ultra-thin gap fillers, high deflection series, and materials that provide electrical isolation.

Thermal Paste

The thermal conductive paste series is used to fill the gap between the electronic chip module and the chassis or radiator module. When mechanical stress is eliminated or batch automatic dispensing is a key design consideration. These materials can fill large and uneven gaps in components, and due to their super flexibility, there is almost no pressure transfer between interfaces. Our thermal conductive gel products include single component form and two-component form, as well as products designed for vertical stability and consistent dispensing, which can meet the efficient operation of customers in large quantities and mechanical dispensing.

Factory production capacity

We have sufficient production capacity: in terms of thermal grease, our monthly output reaches 300 tons, which can fully meet customer needs; in terms of thermal pads, our monthly output is 20,000 square meters, which can adapt to the diverse needs of customers and also support customized services.In addition, we have agency qualifications for internationally renowned brands such as 3M and Laird, and customers can purchase products of these brands through us. Since we cooperate directly with large manufacturers like 3M and Laird, we purchase materials in whole rolls (each roll is 10,000 square meters) and then cut them into the sizes required by customers using our own factory’s die-cutting equipment. Therefore, we can supply goods at a lower cost and with a fast response to delivery dates – this is more advantageous compared to customers purchasing directly from the original factory (which is expensive), and it is also an important reason why many customers choose to cooperate with us.

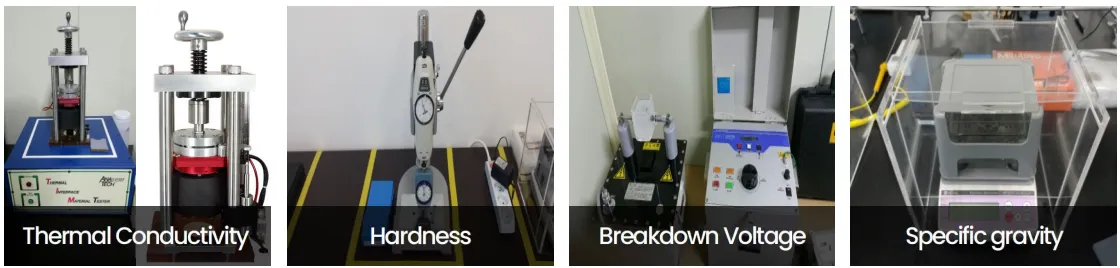

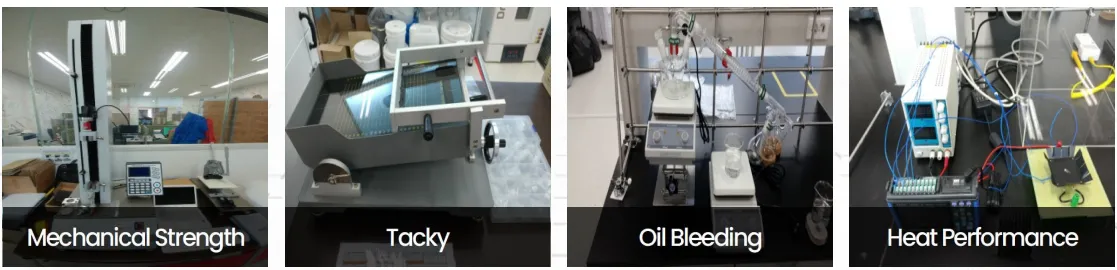

Quality Equipment

In our commitment to delivering top – notch thermal pads and thermal grease, advanced quality equipment is our cornerstone.The thermal conductivity tester precisely measures how effectively heat is transferred, crucial for ensuring optimal thermal management. The hardness tester gauges the material’s resistance to deformation, impacting its usability and durability. The breakdown voltage tester safeguards against electrical failures, especially important in applications where electrical insulation matters.The specific gravity tester helps maintain consistent material density. The mechanical strength tester ensures the materials can withstand physical stress. The tacky tester assesses adhesiveness for proper application. The oil bleeding tester monitors for unwanted oil seepage, and the heat performance tester evaluates how the materials perform under various thermal conditions. These instruments work in tandem to control product quality at every step.

Standard thermal pad 1-5W/m-k thermal conductivity

| WT- JSSU100 |

WT-JSSU100PI | WT-JSS100 | WT-JSS103HD | WT-JSS103 | WT-JSS103G | WT-JSS103PI | WT-JSS103HC | WT-JSS105 | |

| Thickness range in inches and millimeters | 0.020”-0.200” (0.50mm-5.08mm) |

0.020”-0.200” (0.50mm-5.08mm) |

0.020”-0.394” (0.50mm-10.00mm) |

0.020”-0.394” (0.50mm-10.00mm) |

0.020”-0.236” (0.50mm-6.00mm) |

0.010”-0.200” (0.25mm-5.08mm) |

0.010”-0.140” (0.25mm-3.56mm) |

0.020”-0.200” (0.50mm-5.08mm) |

0.020”-0.200” (0.50mm-5.08mm) |

| Thermal conductivity | 1.2 W/m-K | 1.2 W/m-K | 1.5 W/m-K | 2.0 W/m-K | 3.0 W/m-K | 3.0 W/m-K | 3.0 W/m-K | 3.5 W/m-K | 5.0 W/m-K |

| Density | 1.9g/cc | 1.9g/cc | 1.9g/cc | 3.0g/cc | 3.1g/cc | 3.0g/cc | 3.0g/cc | 3.1g/cc | 3.3g/cc |

| Hardness (Shore 00) |

20 | 25 | 40 | 38 | 51 | 40 | 80 | 30 | 50 |

| TML | 0.56% | 0.62% | 0.32% | 0.39% | 0.29% | 0.19% | 0.19% | 0.20% | 0.23% |

| CVCM | 0.10% | 0.11% | N/A | 0.10% | 0.04% | 0.07% | 0.07% | 0.05% | 0.07% |

| Temperature range | -40℃ to 200℃ | -40℃ to 200℃ | -40℃ to 200℃ | -40℃ to 200℃ | -40℃ to 200℃ | -40℃ to 200℃ | -40℃ to 150℃ | -40℃ to 200℃ | -40℃ to 200℃ |

| UL 94 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 |

| Thermal resistance at 40 mils, 10 psi | 0.98℃ -in²/w | 1.50℃ -in²/w | 1.10℃ -in²/w | 0.573℃ -in²/w | 0.62℃ -in²/w | 0.68℃ -in²/w | 0.592℃ -in²/w | 0.482℃ -in²/w | 0.25℃ -in²/w (200 um) |

| Dielectric constant at 1 MHz | 2.7 | 7.45 | TBD | 6.62 | 4.0 @10GHz |

19 | 4.6 | 4.6 | 5.9 |

| volume resistivity (ohm-cm) | 1.1 x 10¹¹ | 1.3 x 10¹² | 2 x 10¹³ | 1.0 x 10¹³ | 1.0 x 10¹³ | 1 x 10¹³ | 2.0 x 10¹⁴ | 1 x 10¹⁴ | 2.2 x 10¹⁵ |

Standard thermal grease 3.5-5.5W/m-k thermal conductivity

| WT-JSS106 | WT-JSS107 | WT-JSS108 | WT-JSS108U | WT-JSS1010 | WT-JSS1010SF | WT-JSS1012 | WT-JSS101013 | WT-JSS101016 | |

| Thickness range in inches and millimeters | 0.040”-0.118” (0.5mm-3.0mm) | 0.020”-0.118” (0.5mm-3.0mm) | 0.020”-0.20” (0.5mm-5.0mm) | 0.020”-0.118” (0.5mm-3.0mm) | 0.010”-0.200” (0.25mm-5.0mm) | 0.040”-0.100” (1.0mm-2.5mm) | 0.020”-0.160” (0.5mm-4.0mm) | 0.020”-0.160” (0.5mm-4.0mm) | 0.040”-0.100” (1.0mm-2.5mm) |

| Thermal conductivity | 6.0 W/m-K | 7.0 W/m-K | 8.0 W/m-K | 8.0 W/m-K | 10 W/m-K | 10 W/m-K | 12 W/m-K | 13 W/m-K | 16 W/m-K |

| Density | 3.3g/cc | 3.3g/cc | 3.4g/cc | 3.4g/cc | 3.3g/cc | 3.4g/cc | 3.1g/cc | 3.2g/cc | 3.3g/cc |

| Hardness (Shore 00) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

TML | 0.34% | 0.33% | 0.34% | 0.36% | 0.33% | 0.33% | N/A | 0.33% | TBD |

CVCM | 0.09% | 0.08% | 0.09% | 0.09% | 0.10% | 0.15% | N/A | 0.15% | TBD |

| Temperature range | -40℃ to 200℃ | -40℃ to 150℃ | -40℃ to 150℃ | -40℃ to 150℃ | -45℃ to 200℃ | -40℃ to 150℃ | -25℃ to 120℃ | -40℃ to 150℃ | -40℃ to 150℃ |

| UL 94 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 |

| Thermal resistance at 40 mils, 10 psi | 0.98℃ -in²/w | 1.50℃ -in²/w | 1.10℃ -in²/w | 0.573℃ -in²/w | 0.62℃ -in²/w | 0.68℃ -in²/w | 0.592℃ -in²/w | 0.482℃ -in²/w | 0.25℃ -in²/w (200 um) |

| Dielectric constant at 1 MHz | 2.7 | 7.45 | TBD | 6.62 | 4.0 @10GHz | 19 | 4.6 | 4.6 | 5.9 |

| volume resistivity (ohm-cm) | 1.1 x 10¹¹ | 1.3 x 10¹² | 2 x 10¹³ | 1.0 x 10¹³ | 1.0 x 10¹³ | 1 x 10¹³ | 2.0 x 10¹⁴ | 1 x 10¹⁴ | 2.2 x 10¹⁵ |

Standard thermal pad 6-16W/m-k thermal conductivity

| WT-TGEL350 | WT-TGEL600 | WT-TGEL900 | WT-TGEL1100 | WT-TGEL350LV0 | WT-TGEL500LV0 | WT-JSS1055AP | |

| material structure | single-component aluminum oxide powder silicon filler | Single-component Aluminum oxide & aluminum nitride powder silicon filler | Two-component aluminum oxide powder silicon filler | ||||

| Colour | pink color | light purple | a light pink color | Grey | part A:Pink | part A:Blue | part A:Grey |

| part B:White | part B:White | part B:Grey | |||||

| Minimum Bondline | 90μ | 90μ | 150μ | 190μ | 85μ | 150μ | 50μ |

| Thermal conductivity (W/m-K) | 3.5 | 6.0 | 9.0 | 11.0 | 3.5 | 5.0 | 5.5 |

| Density(g/cc) | 3.2 | 3 | 3.5 | 3.8 | 3.1 | 3.3 | 3.0 |

Standard thermal pad and grease

We specialize in providing standard thermal pads and thermal grease, committed to offering customers reliable thermal management solutions. Based on the product characteristics and needs of clients across different industries, our standard product range allows customers to quickly find suitable thermal pads and thermal grease, which can be directly applied to their product assembly without the need for additional customization.We always prioritize quality. Each standard product undergoes rigorous performance testing and quality control to ensure stable thermal conductivity and insulation properties in complex environments such as high temperatures and high humidity, laying a solid foundation for the long-term stable operation of customers’ products.Meanwhile, we understand the importance of R&D cycles and time-to-market for customers. By optimizing the supply chain and production processes, we have achieved short lead times for standard products. Customers do not need to wait for a long time and can quickly obtain the required products for R&D testing or mass production, effectively shortening the R&D cycle and helping products enter the market earlier to seize competitive opportunities.