What is a thermal design?

Thermal design can be defined as a systematic design approach implemented during the initial phase of thermal management planning. Its core lies in leveraging advanced software tools to conduct comprehensive computer-aided simulation analyses, with the ultimate goal of generating reliable theoretical data.In practice, this method begins by identifying key variables that influence thermal performance, such as the material and structural parameters of heat sinks, the flow channel design of liquid cooling plates, the rotational speed and air volume of fans, as well as material properties, heat source intensity, and environmental conditions. Engineers then adjust and set these diverse parameters within the simulation software, creating multiple virtual scenarios that mimic real-world operating environments—for example, testing the impact of different heat sink sizes on local temperatures, or altering the combination of coolant flow rates in liquid cooling plates and fan operating power to observe changes in the overall heat dissipation efficiency of the system.

The purpose of thermal design.

The purpose of thermal design is to identify potential risks of chip overheating and find optimal solutions. It involves using software calculations to support product prototyping, verifying results through final tests, and further optimizing based on those findings.However, many engineers—especially newcomers—are unclear about the reasons for conducting thermal design and simulation. They often start working merely to complete tasks without first understanding the objectives and requirements. This approach leads to issues such as missing necessary conditions or using incorrect methods, resulting in significant time waste. Ultimately, they may even question the validity of their results.Thus, the ultimate goal of thermal design for electronic products is to continuously refine the optimal project solution through theoretical calculations, simulation analyses, and experimental testing. This ensures the long-term stable operation of electronic products, preventing equipment malfunctions caused by component overheating.

The significance and value of thermal design.

In other words, why do we need to conduct thermal design simulation analysis. This is mainly reflected in three aspects: reducing costs, shortening research and development cycles, and improving product reliability and competitiveness. Reducing costs mainly manifests in reducing the cost of back and forth sampling and the time cost of repeated testing. Shorten the research and development cycle, quickly validate heat dissipation solutions (such as duct layout and material selection) in virtual environments, and reduce the number of sampling times. A certain enterprise extended the thermal runaway protection time from 58 seconds to 220 seconds through simulation, without the need for repeated trial production. Improve product reliability and competitiveness. We know that if there are design defects or selection issues, it will lead to abnormal equipment operation. If we can understand the design defects in advance, identify the thermal weak areas of electronic components inside the equipment, and optimize and improve their design, it will greatly enhance the reliability of the product in harsh environments and improve its competitiveness.

Walmate can help customers to do a heat sink thermal design.

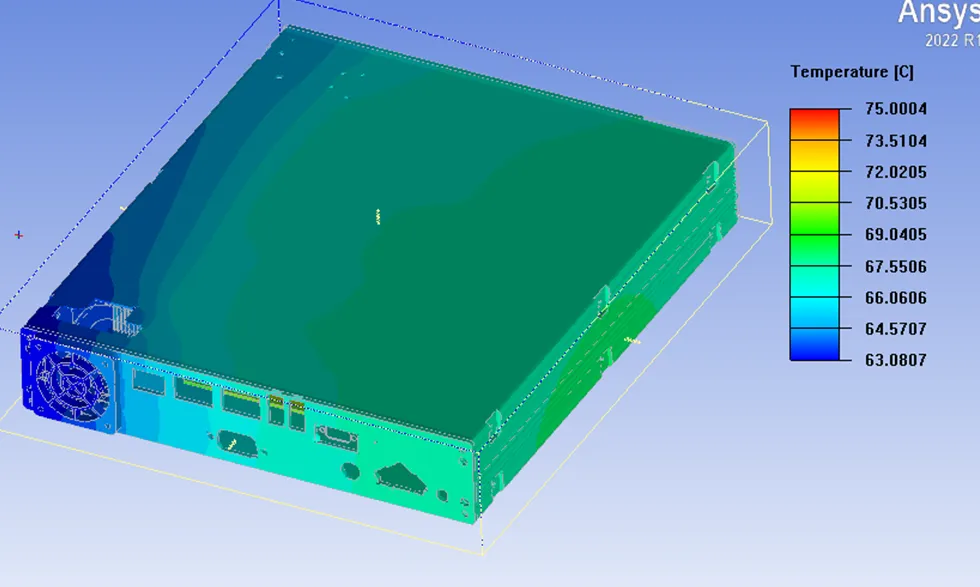

We are capable of providing customers with thermal design services for heat sinks. Typically, when a customer selects a chip, their engineers can supply us with the chip’s specifications, such as its thermal power in watts. Our engineers then perform theoretical calculations to determine the appropriate heat sink solution.The size of the heat sink is largely dictated by these calculations. For chips with high power consumption, we often consider forced convection solutions. Conversely, for low-power chips, natural convection designs are usually sufficient. Through these theoretical computations, we can approximate the required length, width, height, and surface area of the heat sink.We then simulate different air flow rates and pressures to calculate the maximum temperature the chip would reach when paired with the designed heat sink. This theoretical design approach helps customers save significant development time and costs by avoiding unnecessary trial-and-error with physical prototypes.

Walmate can help customers to do a liquid cooling plate thermal design.

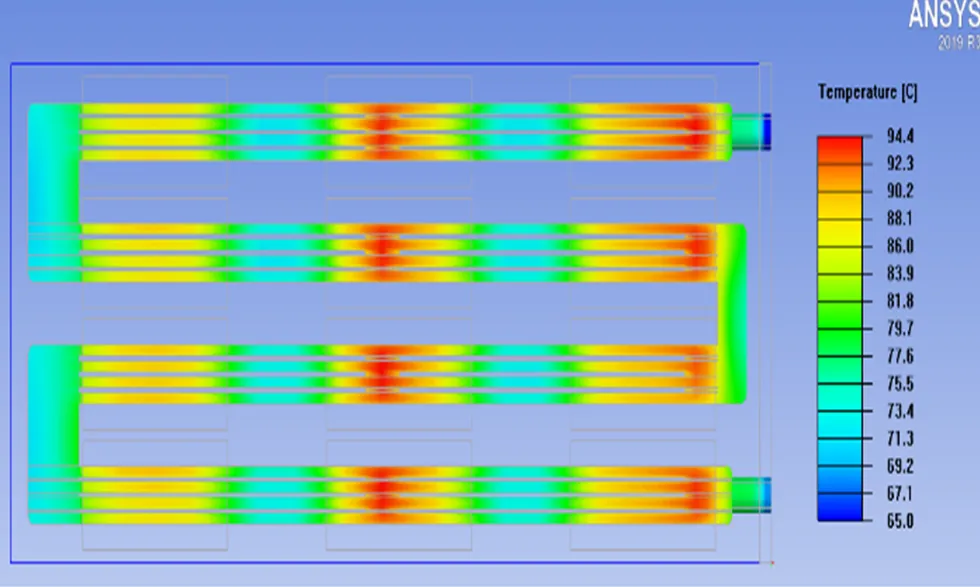

We Similarly, we can also design a thermal solution involving liquid cooling plates for customers. When a customer’s chip operates at extremely high power levels—exceeding the cooling capacity of conventional heat sinks paired with fan,we turn to liquid cooling plates, leveraging the high specific heat capacity of water. This design allows water or coolant to circulate through the interior of the liquid cooling plate, effectively transferring and dissipating large amounts of heat: the heat generated by the chip is absorbed by the coolant, which is then pumped away by a water pump to remove the accumulated thermal energy.In designing such liquid cooling plates, we start with the theoretical power requirements to engineer a suitable solution, including the design of microchannels in the area directly beneath the chip. Through repeated parameter adjustments and simulations, we can achieve the target temperature specified by the customer. This approach also saves significant costs and development time.Thermal design is therefore crucial in liquid cooling plate development, especially given the high manufacturing costs of such components. By using software for simulation and analysis, we can drastically reduce research and development expenses, making the process both efficient and cost-effective.