Engineers and designers face constant trade-offs when choosing materials that balance strength, weight, and heat efficiency. Understanding how metals like copper, aluminum, and steel behave under thermal load is key to optimizing systems where every degree of temperature stability affects performance and lifespan.

This guide examines the thermal conductivity of common metals, compares copper and aluminum in performance-to-cost roles, and explores thickness effects on specific thermal resistance. It helps engineers select materials that drive reliable, efficient, and scalable heat management designs.

Material Science 101: Choosing the Right Base

Choosing the right base material in engineering requires balancing density, strength, stiffness, and cost. Metals generally offer the highest density and strength, ceramics provide mid-range density with high stiffness, and polymers are the lightest but least stiff, making each suitable for different design priorities.

In our experience working with thermal management materials, selecting the proper base depends on how mechanical, thermal, and cost requirements align. Engineers must weigh density, strength, and stiffness against how each factor influences product performance and energy efficiency.

Comparing Base Materials: Density, Strength, and Stiffness

This comparison highlights how metals, ceramics, and polymers differ in density and mechanical properties, which directly affect performance and specific thermal resistance.

| Material Type | Density (g/cm³) | Specific Tensile Strength (unitless) | Specific Modulus (unitless) | Performance Notes |

|---|---|---|---|---|

| Metals (Titanium, Steel, Copper) | 4.5–8.9 | 38,375–40,738 | 15,190–40,738 | ✅ High strength and stiffness, ⚠️ higher density and cost |

| Ceramics (High-alumina) | 2.5–4.0 | 121,085 | 110,341 | ✅ Excellent stiffness, ✅ good thermal stability, ❌ brittle |

| Polymers (ABS, PVC, PTFE) | 0.9–1.4 | 23,092–43,294 | 2,309–23,092 | ✅ Lightest, ⚠️ low stiffness, ⚠️ limited load-bearing ability |

From a cost-to-performance perspective, high-alumina ceramics show the best value in specific tensile strength. Aluminum alloys balance density and cost effectively, while polymers remain ideal when minimizing weight or simplifying manufacturing.

Design Considerations: Matching Material Properties to Applications

Beyond raw mechanical data, engineers must also evaluate cost, manufacturability, and thermal factors such as specific thermal resistance. These aspects determine real-world material effectiveness in demanding environments.

- ⚙️ Metals like titanium and steel are preferred for structural applications that demand high strength and stiffness despite their weight and expense.

- 🧱 Ceramics, especially high-alumina, deliver superior stiffness and temperature resilience but are brittle and harder to machine.

- 🧩 Polymers such as ABS and PTFE are lightweight and affordable but deform more under load and have lower stiffness.

- 🚀 In aerospace or automotive sectors, lower-density materials outperform heavier options when weight savings improve system efficiency.

Walmate Thermal’s R&D experience in material design supports customers in selecting the appropriate substrate based on mechanical, thermal, and environmental demands. Their analysis often integrates specific thermal resistance data to optimize efficiency across power electronics, EVs, and energy storage systems.

The Big Chart: Thermal Conductivity (k) of Common Metals

Thermal conductivity of common metals varies widely, from about 14.4 W/m·K for stainless steel 304 up to 429 W/m·K for silver. Precious metals like silver, copper, and gold offer the highest heat transfer efficiency, while steel and stainless alloys have much lower conductivity.

Engineers and designers rely on accurate thermal conductivity values when selecting materials for cooling systems, enclosures, or heat exchangers. These figures help predict how efficiently a substance conducts heat and inform calculations related to specific thermal resistance and temperature gradients. Here’s a detailed look at how different metals perform under typical conditions.

Thermal Conductivity Values of Common Metals

The following table compares widely used metals by their approximate thermal conductivity at 20 °C, along with notes on their typical usage and alloy influence.

| Metal | Thermal Conductivity (W/m·K) | Notes |

|---|---|---|

| Silver | 406–429 | ✅ Highest among pure metals; ideal for precision heat transfer. |

| Copper | 397–401 | ✅ Benchmark for thermal management applications. |

| Gold | 315–318 | ✅ Excellent conductor; used in high-end electronic contacts. |

| Aluminum | 205–237 | 🚀 Lightweight and widely used in electronics and automotive systems. |

| Brass (Cu70% Zn30%) | 109–125 | 💡 Conductivity varies with alloying ratios. |

| Pure Iron | ~80 | ⚙️ Moderate conductor used in structural components. |

| Carbon Steel | 45–60 | ❌ Lower conductivity; suitable for structural and thermal isolation design. |

| Stainless Steel 304 | 14.3–16 | ⚠️ Low conductivity, preferred for thermal barriers. |

| Tin / Zinc | Variable | ⚠️ Conductivity declines with higher temperatures. |

Impact of Alloy Composition and Temperature on Thermal Conductivity

Adding alloying elements to a pure metal usually introduces lattice distortions that scatter free electrons, causing significant drops in thermal conductivity. For instance, stainless steel 304’s conductivity is about 97% lower than copper’s due to chromium and nickel content. Metal alloys such as brass display a similar pattern—higher zinc proportions lead to poorer heat conduction.

Temperature also influences how efficiently metals transfer heat. Tin and zinc are known to lose conductivity as the temperature rises, which matters for parts consistently exposed to high operational heat. Walmate Thermal considers these variations when modeling specific thermal resistance profiles for critical applications, ensuring system stability and performance.

Engineering Applications and Material Selection

When selecting materials for heat dissipation or insulation, engineers weigh both conductivity and practical aspects such as cost, weight, and fabrication ease.

- ✅ High conductivity metals like silver and copper excel in heat exchangers, electronics cooling, and cookware.

- ✅ Lower conductivity alloys such as stainless steel suit thermal barriers and insulation components.

- 💡 Copper often becomes the practical choice due to its performance-to-cost balance.

- ⚠️ Designers must factor in temperature-dependent changes to conductivity and environmental effects during operation.

In our experience at Walmate Thermal, optimizing these variables leads to more predictable performance in solutions such as EV battery cooling plates and industrial inverter assemblies.

Common Misconceptions About Thermal Conductivity of Metals

- ❌ Not all metals conduct heat equally—the range across common alloys spans roughly 30×.

- ⚠️ Assuming an alloy retains the thermal properties of its base metal often leads to poor material selection.

- 💡 Thermal conductivity isn’t fixed; it must be checked at the relevant operating temperature for accurate modeling.

- ✅ Engineers also weigh cost, strength, and corrosion resistance alongside conductivity when making selections.

Understanding real-world data on conductivity and specific thermal resistance helps refine designs that balance thermal efficiency, structural integrity, and economic feasibility in demanding applications.

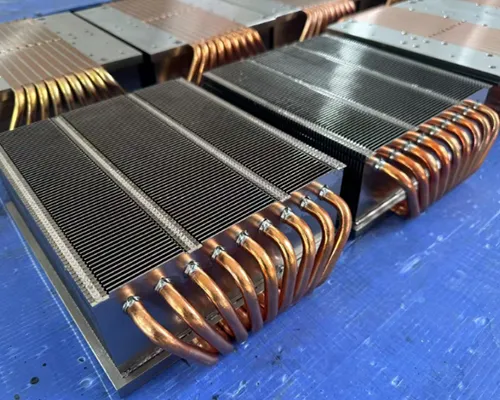

Copper vs. Aluminum: The Standard Bearers

Copper offers nearly twice the thermal conductivity of aluminum, making it the superior choice for maximum heat transfer. Aluminum, though less conductive, is significantly lighter and more cost-effective, suitable for applications prioritizing weight and budget over peak thermal performance.

Engineers often weigh copper and aluminum when optimizing for specific thermal resistance, cost, and material efficiency. Both materials are cornerstones in advanced heat sink and cooling system design, especially in Walmate Thermal’s applied solutions for EV, power electronics, and renewable energy systems.

Thermal Conductivity and Physical Properties Comparison

This comparison highlights how copper and aluminum differ in performance-critical properties that influence thermal design efficiency and structural choices.

| Property | Copper 🧱 | Aluminum ⚙️ | Notes 💡 |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 385–401 | 205–237 | Copper is up to ✅ 2x more conductive |

| Thermal Conductivity (BTU/hr·ft·°F) | 231 | 136 | Copper conducts 🔥 heat about 70% better |

| Relative Conductivity | ✅ 100% | ⚠️ 60% | Baseline comparison for electrical and heat transfer |

| Density | Higher mass | ✅ 33% lighter | Aluminum offers weight savings in large systems |

| Cost | ❌ Higher | ✅ 40–60% cheaper | Aluminum supports high-volume production budgets |

Material Behavior and Design Considerations

In our engineering experience, copper’s atomic structure includes more free electrons per atom, improving thermal conduction performance. With 4 more free electrons than aluminum, copper provides faster heat diffusion at the microscopic level. Yet under higher temperatures, conductivity can drop due to atomic vibration effects.

Aluminum maintains more consistent conductivity with temperature changes and has a comparatively higher specific heat capacity, which helps absorb thermal energy without quick spikes in surface temperature. This is one reason why aluminum remains popular in high-power but lightweight systems such as inverter housings and battery modules.

- 💡 Aluminum radiators frequently use wider tubes (1–1.25 inches) compared to copper (3/8 inch) to increase contact area.

- ⚙️ Optimized geometry can balance out raw conductivity differences.

- ✅ Proper design helps achieve equivalent performance in systems with different material bases.

Applications and Cost-Performance Trade-offs

When considering real-world implementations, both materials find their place according to project priorities. Walmate Thermal often matches copper and aluminum cooling modules based on space, cost, and specific thermal resistance requirements of the end system.

- 🚀 Copper is the top choice for electronics cooling, high-performance heat sinks, and heat exchangers where rapid heat spreading is crucial.

- ⚙️ Aluminum dominates in automotive, aerospace, and scalable industrial manufacturing, where low weight and affordability are decisive.

- 💡 Cost differentials matter — aluminum’s lower price delivers overall savings of 40–60% over copper.

- ✅ Aluminum improves fuel efficiency and manufacturing ease due to its lightweight nature.

- ⚠️ Silver outperforms both metals thermally but remains cost-prohibitive for most industrial applications.

By integrating copper and aluminum options, Walmate Thermal designs system-level cooling solutions that align with clients’ specific thermal resistance targets and production budgets. Each project balances material science with detailed geometric design to achieve both reliability and efficiency across industries like EV, automation, and power electronics.

Elevate Your Product Performance with Precision Thermal Solutions

Partner with Walmate Thermal to leverage nearly two decades of expertise in custom, system-level thermal management designed to optimize efficiency and reliability across power electronics, EVs, and more. Our expert engineers and advanced manufacturing capabilities ensure scalable, high-quality solutions tailored to your unique needs.

The “Steel Trap”: Why You Never Use Steel in a Thermal Path

Steel—especially stainless steel—should not be used in a thermal path because its thermal conductivity is significantly lower than other common metals, resulting in poor heat transfer and higher thermal resistance compared to alternatives like aluminum or copper.

In our experience working with advanced cooling systems, steel often turns into a performance limiter rather than a solution. This section explores how steel compares to more conductive metals, why it creates a thermal bottleneck, and which materials engineers should select for efficient heat management.

Thermal Conductivity Comparison of Common Metals

Thermal conductivity is one of the most direct indicators of how well a material transfers heat. Different metals exhibit major differences in this property, leading to significant variations in specific thermal resistance when used in real applications.

| Metal | Thermal Conductivity (W/m·K) | Performance |

|---|---|---|

| Copper | ~400 | 🚀 Excellent conductor |

| Aluminum | ~235–237 | ✅ Good balance of weight and conductivity |

| Carbon Steel | 45–59 | ❌ Moderate but inefficient for heat transfer |

| Stainless Steel (Type 304) | 14–30 | ⚠️ Very poor conductor in thermal paths |

| Brass | ~109 | ✅ Moderate performance, better than steel |

| Titanium | ~22 | ❌ Low conductor, high strength |

| Iron | ~80 | ✅ Better than steel, still poor compared to copper |

From this comparison, copper and aluminum clearly outperform steel by large margins, often resulting in heat transfer efficiencies several times higher.

Why Steel Creates a Thermal Bottleneck

Steel’s alloyed makeup, containing chromium, nickel, and other additives, drastically reduces its ability to conduct heat. This composition transforms steel into a thermal choke point within heat flow paths.

- ⚠️ Steel’s low conductivity compared to copper or aluminum introduces measurable thermal resistance, often turning the system into what engineers call a “steel trap.”

- ❌ When used in heat sinks or cooling plates, steel delays heat dissipation and raises component temperature.

- ⚠️ Higher operating temperatures can cause overheating, reduce lifespan, and lower overall system reliability.

- 💡 Although strong and corrosion-resistant, steel should serve non-thermal structural roles rather than positions requiring heat transfer.

In thermal management designs, minimizing specific thermal resistance is critical to maintaining performance stability. Substituting steel for higher-conductivity metals leads to measurable efficiency improvements.

Preferred Metals for Thermal Paths

To achieve superior thermal performance, Walmate Thermal often recommends metals specifically optimized for heat transfer.

- 🚀 Copper offers the highest thermal conductivity (~400 W/m·K), making it a top choice where rapid heat spreading is essential.

- ✅ Aluminum, at around 235–237 W/m·K, provides an ideal mix of thermal efficiency, light weight, and cost-effectiveness.

- 💡 Both materials significantly reduce junction temperatures compared to steel and support efficient cooling even under heavy thermal loads.

- ⚙️ Engineers should prioritize conductivity over structural strength when designing thermal paths, reserving steel for casings or support elements instead.

Walmate Thermal integrates these metals into its heat sinks, liquid cooling plates, and system-level designs to maintain low resistance and high thermal performance. This approach helps critical systems—from power electronics to EV batteries—stay within safe operating ranges while maximizing lifespan and reliability.

Brass, Gold, and Silver: Good Conductors, Bad Choices?

Brass, gold, and silver are all good electrical conductors, but they are often poor choices for practical wiring due to cost, mechanical properties, and relative conductivity compared to copper. Silver is the best conductor but is expensive and tarnishes; gold resists corrosion but is costly; brass is much less conductive than copper and typically used only when its mechanical advantages outweigh its lower conductivity.

In our experience with thermal and electrical system design, understanding both conductivity and cost helps engineers make informed material choices. The metals below are compared based on standard conductivity values and real-world usage considerations.

Electrical Conductivity and Cost Comparison

Conductivity and cost differ significantly among these metals. While silver tops the chart in electrical performance, copper remains dominant when cost and mechanical stability are weighed together.

| Material | ⚡ Electrical Conductivity (% IACS) | 🔌 Conductivity (S/m) | 💰 Approx. Cost |

|---|---|---|---|

| Silver | 105% | – | $700/kg |

| Copper | 100% | 5.96 × 10⁷ S/m | $9/kg |

| Gold | 70% | 4.11 × 10⁷ S/m | $60,000/kg |

| Brass | 28% | – | $5–7/kg |

These figures reveal that while silver conducts electricity better than copper, its high price and surface tarnish reduce practicality. Gold, though resistant to corrosion, carries an even higher price tag, making it suitable mostly for precision contacts. Brass, on the other hand, trades conductivity for mechanical toughness and cost efficiency.

Mechanical Properties and Application Suitability

The choice of material also reflects mechanical and environmental needs. In thermal system manufacturing like that offered by Walmate Thermal, such material factors directly affect efficiency and thermal management behavior, including specific thermal resistance.

- 💡 Silver: Offers the highest conductivity but tarnishes, limiting it to specialized connectors or RF applications where corrosion can be controlled.

- 💡 Gold: Provides strong corrosion resistance, ideal for contacts or edge connectors where a stable, low-resistance interface is needed despite high cost.

- 💡 Brass: As a copper-zinc alloy, it’s easier to machine, non-magnetic, and affordable. Common in terminals, fittings, and radiator parts when conductivity is less critical.

In our R&D observations, gold and silver are rarely used for bulk conductors. Their strength lies in surface and contact engineering where corrosion resistance or conductivity must remain consistent over time.

Critical Perspective on Using Brass, Gold, and Silver

It’s a common misconception that because brass contains copper, it should conduct electricity nearly as well. The truth is, added zinc and other elements severely lower its conductivity to around 28% IACS.

- ⚠️ Substituting brass or gold for copper: Demands attention to conductivity drop and cost inflation before implementation.

- ✅ Copper remains the preferred material: It provides a strong balance between cost, conductivity (100% IACS), and availability.

- 💡 Thermal context: Copper’s consistent performance under high current and low specific thermal resistance keeps it irreplaceable in wiring, busbars, and thermal plates designed by Walmate Thermal.

For high-performance applications like power electronics cooling or EV battery systems where both heat and current density matter, Walmate Thermal incorporates copper-based designs to minimize thermal and electrical losses while maintaining manufacturability.

Exotic Materials: Diamond and Graphene Values

Diamond and graphene are both exotic materials with outstanding thermal and mechanical properties. Graphene surpasses diamond in thermal conductivity (up to 5,000 W/m·K), while diamond remains the hardest known material used in premium semiconductor applications.

Engineers often compare diamond and graphene when evaluating materials for applications requiring extremely low specific thermal resistance. Each offers unique benefits that can transform the performance of semiconductor and thermal systems.

Thermal and Electrical Conductivity Comparison

Both diamond and graphene show exceptional heat transport characteristics, but graphene leads with record-breaking conductivity. The following data highlights their differences in thermal and electrical performance.

| Property | Graphene | Diamond |

|---|---|---|

| 💡 Thermal Conductivity | 3,000–5,000 W/m·K | 2,000–2,200 W/m·K |

| ⚡ Electrical Conductivity | Approximately 200× higher than copper | Acts as an insulator unless doped |

In our experience helping OEMs manage heat in advanced systems, graphene’s extremely high conductivity makes it a prime candidate for flexible electronics and heat spreaders, while diamond’s balanced thermal and electrical properties serve high-voltage environments.

Mechanical Strength and Material Hardness

The mechanical performance of diamond and graphene determines how they are used in critical applications. Graphene offers unmatched tensile strength, while diamond provides superior compressive strength and wear resistance.

| Property | Graphene | Diamond |

|---|---|---|

| 💪 Tensile Strength | 130 GPa (about 100× stronger than steel) | Moderate tensile strength |

| 🧱 Compressive Strength | N/A | 60 GPa, the hardest known solid material |

While graphene’s strength opens possibilities for flexible composites, diamond’s hardness is irreplaceable in cutting, grinding, and semiconductor devices requiring extreme durability under thermal stress.

Market Size, Growth, and Pricing Overview

The commercial position of each material reveals their maturity and adoption rate across industries. The table below summarizes their market valuations and cost ranges.

| Metric | Graphene | Diamond (Semiconductor) |

|---|---|---|

| 💰 Market Size (2025) | $1.22–$1.62 billion | $113.67 million |

| 🚀 Projected CAGR (2025–2030) | 24.0% | 26.3% |

| 💲 Price Range | Nanoplatelets: $50–$500/kg | Wafers: $1,000–$10,000/wafer |

Both markets show strong growth potential. Graphene scales through diverse applications, while diamond’s high value stems from its technical and manufacturing complexity in advanced electronics.

Production Challenges and Supply Considerations

Despite impressive properties, both materials face real-world production barriers that affect cost and availability. Quality consistency is key for scalable industrial use.

- ⚠️ Graphene production faces high costs and scalability issues due to process variations.

- ⚠️ Diamond production requires specialized equipment and controlled environments.

- 💡 Supply chain maturity and purity consistency determine long-term feasibility in commercial adoption.

From our engineering perspective, manufacturers must evaluate not only material performance but also upstream logistics and quality reproducibility when planning for system integration or partnership sourcing.

Practical Applications and Critical Perspectives

Both diamond and graphene occupy essential roles in advanced technologies. Their distinctions are better viewed as complementary rather than competitive advantages.

- ✅ Graphene: ideal for next-generation electronics, energy storage, structural composites, and nano-filtration systems.

- ✅ Diamond: crucial for cutting tools, high-power electronics, heat spreaders, and quantum information systems.

- ⚠️ Graphene is not yet ready to replace metals or ceramics entirely due to scaling and cost constraints.

- 💡 Engineers must examine specific thermal resistance, performance-to-cost ratio, and integration compatibility before selection.

In our experience at Walmate Thermal, understanding each material’s performance and thermal behavior helps optimize system-level cooling designs. Whether specifying graphene for conductive coatings or diamond substrates for semiconductor platforms, careful selection ensures reliability in demanding environments.

Specific Thermal Resistance: The Thickness Factor

Specific thermal resistance increases proportionally with material thickness: doubling thickness doubles thermal resistance if thermal conductivity and area remain constant.

In our engineering practice, understanding how thickness affects specific thermal resistance is key to selecting materials for insulation or heat conduction. The thicker a layer becomes, the higher the resistance to heat flow—provided that thermal conductivity and surface area remain unchanged.

Thermal Resistance Formula and Practical Examples

The basic relationship governing this property can be expressed as:

- 💡 Thermal Resistance (R) = Thickness (L) ÷ (Thermal Conductivity (k) × Area (A))

Below are several practical examples showing how changing thickness impacts specific thermal resistance:

| Material Example | Thermal Conductivity (k) | Thickness (L) | Area (A) | Thermal Resistance (R) | Performance Summary |

| Insulation material | 0.04 W/m·K | 0.05 m | 1 m² | 1.25 m²·K/W | ✅ Efficient balance of thickness and insulation |

| Same material (double thickness) | 0.04 W/m·K | 0.10 m | 1 m² | 2.5 m²·K/W | 🚀 Thermal resistance doubled |

| Polystyrene foam (thin layer) | 0.033 W/m·K | 0.001 m | 1 m² | 0.03 m²·K/W | ❌ Minimal insulation capacity |

| Glass panel | 1.0 W/m·K | 0.1 m | 1 m² | 0.1 m²·K/W | ❌ Poor insulator despite thickness |

| Porous aerogel | 0.015 W/m·K | 0.05 m | 1 m² | 3.33 m²·K/W | ✅ Exceptional insulation performance |

These figures show that thermal resistance increases linearly with thickness. But the conductivity value largely determines whether the increase has meaningful impact.

Material Thickness, Porosity, and Thermal Efficiency: A Critical Perspective

Increasing thickness improves resistance to heat flow, yet beyond a certain point, gains may flatten due to design limits or cost. Thin coatings, though efficient in conductivity terms, cannot offset their minimal thickness.

Porous materials offer a different behavior — they trap air, lowering conductivity and boosting insulation without needing excessive thickness. This is why aerogels and foams are favored for lightweight applications.

- 💡 Thicker layers generally yield better resistance, though with diminishing returns at extreme levels.

- ⚠️ Thin coatings with high-performance conductivity may not substitute for bulk insulation.

- ✅ Porous materials like foams effectively limit heat transfer while saving weight.

- 🚀 Engineering design must balance thickness, porosity, cost, and space constraints to achieve practical efficiency.

For engineers and designers, achieving optimal specific thermal resistance calls for an integrated approach. In our experience at Walmate Thermal, ideal results come from designing systems where geometry, material structure, and application requirements align for both performance and manufacturability.

The Garage Guru’s Cheat Sheet for DIYers

The “Garage Guru’s Cheat Sheet for DIYers” offers expert tips and checklists to help DIYers manage common garage tasks efficiently, emphasizing safety, proper tools, and maintenance best practices.

For hands-on homeowners who enjoy improving their garage setup, this section breaks down expert advice into practical, easy-to-follow guides. Each topic helps you plan projects better, avoid costly mistakes, and maintain a safer workspace.

Cost and Time Considerations for Garage Projects

Planning your garage project starts with understanding typical costs and time expectations. Repair and installation jobs can vary based on the complexity of the system and custom features. Below is a quick look at average expenses and timeframes:

| 🔧 Project Type | ⏱️ Typical Duration | 💰 Average Cost (USD) | 📜 Warranty Terms |

|---|---|---|---|

| Garage Door Repair | 3–4 hours | $150–$375 | 30-day labor warranty |

| Garage Door Installation | 3–6 hours | Varies by door type | Manufacturer warranties |

| Custom Garage Organization System | 1–2 days | $1,500–$5,000 (Denver, CO) | Lifetime on structural components |

Setting realistic timelines prevents rushed work, while knowing your warranty coverage helps you plan long-term maintenance wisely.

Essential Safety and Maintenance Tips for DIY Garage Projects

Before starting any DIY project, safety should always come first. A well-maintained workspace not only protects you from injuries but also extends the life of your tools and equipment.

- ⚠️ Test the auto-reverse safety feature on garage doors monthly to prevent closing hazards.

- 💡 Lubricate moving parts every six months for smooth and quiet operation.

- ⚠️ Inspect cables and springs quarterly for fraying or tension issues.

- ✅ Always wear personal protective gear such as safety glasses and gloves when working with power tools.

- ⚠️ Be aware of the high tension in garage door springs and the risks of electrical components—some repairs should be left to professionals.

Recommended Tools for Garage DIY Projects

Having the right tools makes every project easier and safer. These essentials are useful across a range of common repair and installation tasks.

- 🔩 Power drill (corded or cordless) for drilling and fastening tasks.

- 🔧 Socket set with both metric and SAE sizes for compatibility.

- 📏 Level of at least 24 inches to keep shelves and mounts properly aligned.

- 📍 Stud finder for locating secure framing within walls before drilling.

- 🧤 Safety glasses and gloves to protect against dust, splinters, and debris.

With these items, DIYers can handle most garage improvements confidently while maintaining precision and safety.

Common Misconceptions and Expert Advice for DIYers

Many home enthusiasts underestimate how complex certain garage systems can be. Understanding these common misconceptions can save time and prevent serious damage.

- ⚠️ Handling high-tension garage door springs without expertise can cause serious injury. This task should always be done by professionals.

- ✅ Custom storage systems often increase usable space by up to 40% compared to generic units.

- 💡 Routine maintenance using manufacturer checklists improves reliability and extends component life.

- 🚀 Consulting professional guides and instructional platforms helps troubleshoot issues and improves long-term project success.

In our experience, combining the right tools with a realistic understanding of project limitations ensures safer, more efficient garage work for every DIYer.

FAQs: About Material Thermal Properties

What material has the lowest thermal resistance?

Thermal resistance measures how well a material resists heat flow. A lower value means heat travels through it more easily. Materials like diamond and silver exhibit extremely low thermal resistance because of their highly conductive crystal and electron structures.

In contrast, ceramics and polymer composites show higher specific thermal resistance, which makes them suitable for insulation applications where controlling heat transfer is critical in electronic or automotive design.

Is brass a good heat conductor?

Brass is a fair heat conductor but not as efficient as copper or aluminum. Its thermal conductivity ranges around 100–125 W/m·K, which is significantly lower than copper’s 385–400 W/m·K.

Engineers sometimes choose brass when a balance between conductivity and corrosion resistance is required, such as in fittings or connectors.

Thermal conductivity of aluminum alloys?

Most aluminum alloys fall within the range of 120–200 W/m·K depending on their composition and temper. Pure aluminum is higher, near 237 W/m·K.

Aluminum’s moderate density and good conductivity make it a popular base for heat sinks, extrusions, and lightweight thermal management parts, especially in electric vehicles and power electronics managed by companies like Walmate Thermal.

Why not use Silver or Diamond?

Silver and diamond have exceptional heat conductivity—about 430 W/m·K and over 1000 W/m·K respectively. The limitation is cost and manufacturing practicality.

These materials provide excellent thermal performance, but their price and processing challenges make them impractical for most industrial applications. Engineers often prefer copper or aluminum, which offer an efficient ratio between conductivity, cost, and structural workability.

Graphite vs. Copper: Which is better?

Both materials serve vital but different roles in thermal management. Copper is an isotropic conductor offering uniform thermal distribution with conductivity around 385 W/m·K.

Graphite is anisotropic, meaning it conducts heat better in-plane (300–500 W/m·K) than through its thickness (5–10 W/m·K). This makes graphite valuable for compact electronics where directional heat spreading is required.

Walmate Thermal often uses composite solutions that combine graphite’s directional control with copper or aluminum baseplates to optimize specific thermal resistance across system-level assemblies.

Final Thoughts

Across metals, ceramics, polymers, and even exotic materials like diamond and graphene, effective thermal design depends on more than just conductivity values. Weight, cost, and specific thermal resistance all shape how heat moves through a system. Copper and aluminum stand out as the practical standards, while material thickness and structure determine how efficiently designs manage energy flow and stability.

By applying these material insights, engineers can create systems that stay cooler, last longer, and perform more consistently. Partnering with a trusted supplier like Walmate Thermal helps translate this data into real-world solutions that align with both technical and commercial goals—from EV cooling plates to power electronics and high-performance insulation components.