Our businesses

offer thermal management solutions and products across various fields for our customers. In some specialized areas, our technical expertise and capabilities enable us to effectively solve numerous problems for our clients.

Our Businesses

Get a Quotation

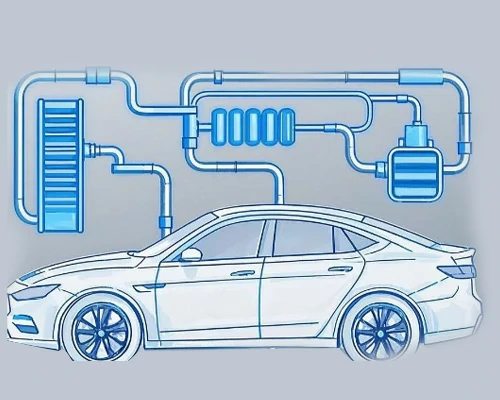

eMobility Thermal Management

The thermal management of electric vehicle batteries involves intense chemical reactions and increased side reactions inside the battery under high temperature conditions or high current charging modes, resulting in a decrease in battery capacity and a shortened range. Similarly, in low-temperature environments, the chemical properties inside the battery decrease, making it impossible for the battery to operate and work under low-temperature conditions. Therefore, thermal management in electric vehicles is particularly important. The liquid cooling plate for battery pack modules used in electric vehicles produced by Walmate Thermal can solve these problems.

Data Center

Data Centers: With the acceleration of the digitalization process, the scale of data centers is constantly expanding, and the problem of equipment heat generation has become more prominent. The high-performance thermal management solutions we introduce can quickly discharge the heat in the data centers, maintain a constant temperature in the computer rooms, ensure the normal operation of servers and other equipment, and provide a solid guarantee for the efficient operation of data centers.

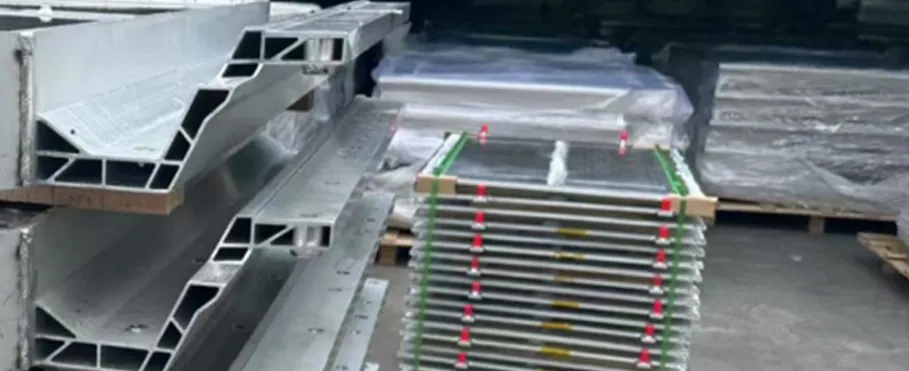

Southern China Manufacturing Base

Located on Liujiaxin North Road, Hengli Town, Dongguan City, Guangdong Province. In this production base, there are more than 10+ complete production lines for car pallets, battery pack module liquid cooled plates, energy storage liquid cooled plates, etc. The complete automated production lines can ensure our daily production capacity of 2000 liquid cooled plates for shipment. In 2024, the annual output value of this workshop is 200 million yuan, making it our largest production base.

Medical Industry

Medical equipment has extremely high requirements for the stability of the operating environment, and temperature fluctuations may affect the accuracy of test results. Our tailor-made thermal management solutions for medical equipment can precisely control the equipment temperature, ensure the stable operation of the equipment, and provide strong support for the technological progress of the medical industry.

New Energy Inverter

Photovoltaic modules generate heat under sunlight exposure, which affects the power generation efficiency. Our developed heat dissipation solutions can effectively reduce the temperature of photovoltaic modules, improve their power generation efficiency, extend their service life, and contribute to the sustainable development of the photovoltaic industry.

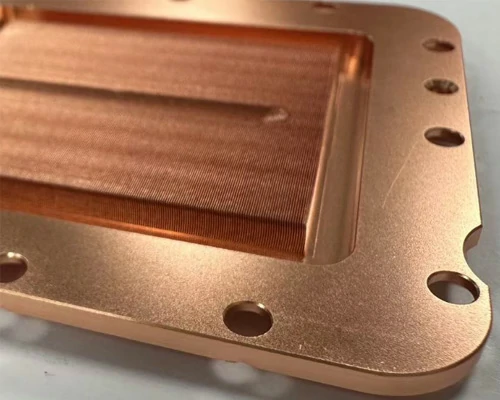

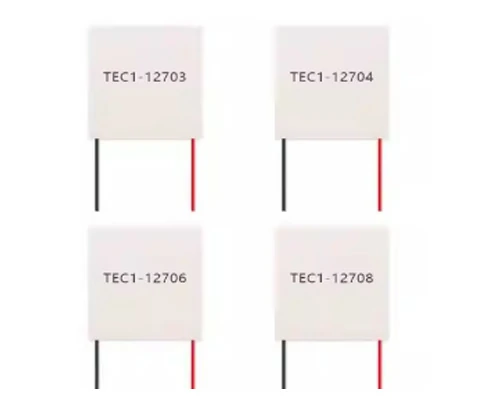

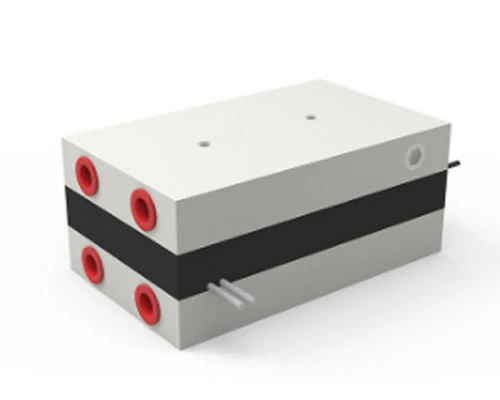

Battry Cooling

In modern society, batteries power diverse devices from cellphones to electric vehicles. However, batteries generate heat during operation. Battery thermal management plays a crucial role. It ensures stable battery performance, preventing overheating that may lead to capacity degradation or even safety risks.For instance, in electric cars, effective thermal management can extend battery lifespan and driving range. The industry continues innovating, using advanced cooling techniques and smart controls to optimize battery thermal management, propelling development across multiple sectors.

LED Lighting

LED lighting thermal management matters because heat accumulation impacts luminous efficacy, color quality, and lifespan. For example, overheating in automotive headlights poses safety risks.It allows design flexibility—slimmer fixtures—while maintaining reliability, crucial in both home and commercial setups. Heat dissipation safeguards LED chips, preventing permanent damage, so thermal management is key to LED lighting’s future.

Across new energy vehicles, energy storage, industrial manufacturing, data centers, photovoltaic industry, and medical equipment , Walmate thermal has established ourselves as experts in thermal management. Our state – of – the – art technologies ensure stable equipment operation, extend product lifespan, and enhance overall performance. With customized solutions, we safeguard clients’ interests, optimizing thermal efficiency and driving industry – wide progress.