What is a heat pipe heat sink?

In the field of heat dissipation solutions, heat pipe heat sinks are highly favored for their efficient heat dissipation performance. To design a heat pipe radiator that meets the customer’s requirements, we need to start from several key aspects.

Firstly, the customer’s required power is the core starting point of the design.

Different powers correspond to different heat generation amounts. Higher power means more heat needs to be dissipated. For example, low-power electronic components may only require a relatively small-sized heat pipe, while high-power server chips need thicker and longer heat pipes to quickly transfer heat. By accurately understanding the customer’s required power, we can initially determine the size and length of the heat pipe, ensuring that the heat pipe has sufficient heat transfer capacity and laying the foundation for the subsequent design.

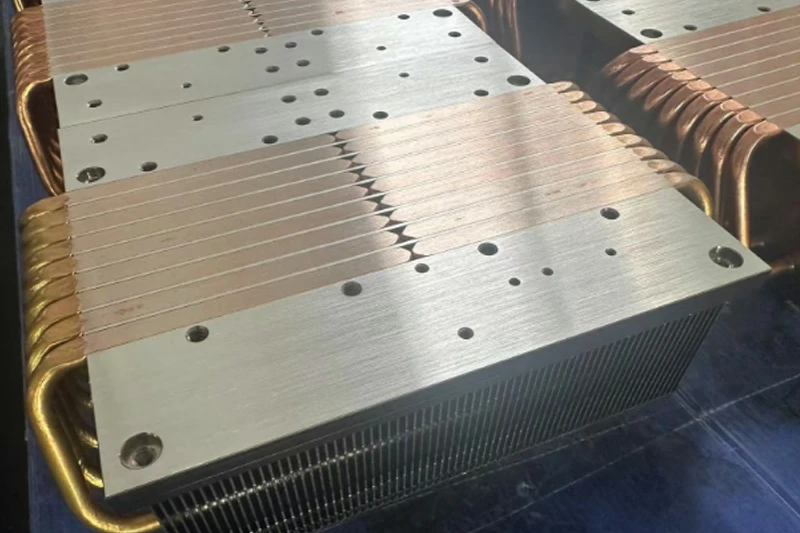

Secondly, the selection of materials and welding processes is of great importance.

Aluminum fins have the advantages of light weight and low cost, and are suitable for scenarios where weight is a concern and the heat dissipation requirement is relatively not very demanding. Copper fins, on the other hand, perform excellently in high heat load environments due to their excellent thermal conductivity. In terms of the welding process, whether it is aluminum fins or copper fins, the welding quality needs to be ensured to reduce the thermal resistance and ensure that the heat can be smoothly transferred from the heat source to the surface of the fins.

Next, calculating the fin area is a crucial step. Based on the required power and the heat transfer capacity of the selected heat pipe, and combined with principles such as convective heat transfer, calculate the fin area that can effectively dissipate heat into the environment. A reasonable fin area can improve the heat dissipation efficiency, avoiding heat accumulation due to insufficient area or causing space waste and increased costs due to excessive area.

Subsequently, the selection of the fan should match the fin area and heat dissipation requirements.

Parameters such as the air volume and air pressure of the fan directly affect the heat dissipation effect. A fan with a large air volume can accelerate the air flow speed and enhance convective heat transfer, but it will also bring higher noise and energy consumption. Therefore, it is necessary to comprehensively consider the usage scenario of the radiator and the customer’s acceptance of noise and energy consumption, and select a suitable fan.

Finally, optimize the space of the radiator. On the premise of meeting the heat dissipation performance, reasonably arrange the heat pipe, fins, and fan, so that the radiator can better fit the installation space of the customer’s equipment. This may involve adjusting the direction of the heat pipe, the arrangement of the fins, etc., to ensure that the radiator can exert its maximum efficiency within the limited space.

In conclusion, designing a heat pipe heat sink requires a comprehensive consideration of multiple factors such as the customer’s required power, materials and processes, fin area, fan selection, and space optimization. Each link is interrelated. Only by achieving accurate design and reasonable planning can we create an efficient and reliable heat pipe heat sink product.