eMobility

eMobility emerges as a prime option for urban transport. Its capacity to lower air pollutants makes it essential for achieving environmental targets in cities.

Our Businesses

Get a Quotation

eMobility Thermal Management

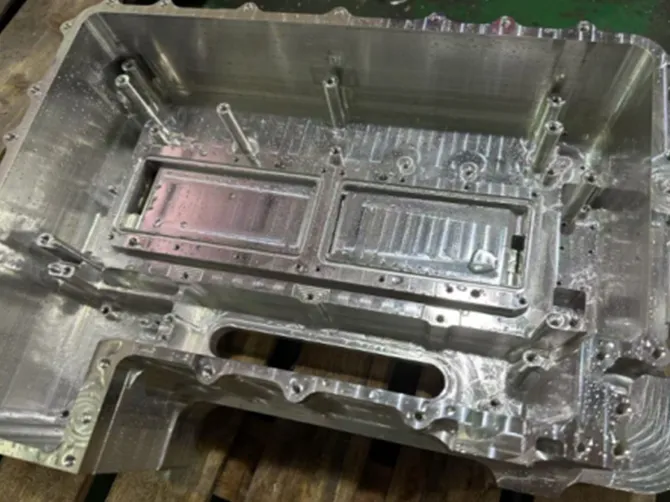

The thermal management of electric vehicle batteries involves intense chemical reactions and increased side reactions inside the battery under high temperature conditions or high current charging modes, resulting in a decrease in battery capacity and a shortened range. Similarly, in low-temperature environments, the chemical properties inside the battery decrease, making it impossible for the battery to operate and work under low-temperature conditions. Therefore, thermal management in electric vehicles is particularly important. The liquid cooling plate for battery pack modules used in electric vehicles produced by Walmate Thermal can solve these problems. so how to design a liquid cooling plate?

Walmate Thermal has advantages in producing liquid cooling plates for electric vehicles

– We produce and supply battery trays and liquid cooled plates of different specifications and styles for BYD, Tesla, and Xiaopeng Motors.

– We can produce 2.8-meterx3-meter-long liquid cooling plates and battery trays.

– Precise argon fluorine welding process and automated welding fixtures ensure the reliabilityand stability of welding.

– Customized leak detection fixtures for 100% full inspection of products.

– A production base of 30000 square meters can meet customers’ order needs.

The Motor Thermal Management

Demagnetization and Insulation Damage due to Overheating: When the motor is running, heat will be generated. Overheating will demagnetize the windings and magnetic materials of the motor, reducing the performance of the motor. At the same time, it may also damage the insulation system and cause electrical safety problems.

Durability under High Load: When running under high load, the motor generates more heat, which is a great test for the heat dissipation capacity of the thermal management system and the durability of the motor. If the heat dissipation is not timely, it may lead to premature damage of the motor.

-After the samples are developed, customers usually use Walmate Thermal to produce them through precision CNC machining, test the operation of the entire water cooling system, and then mass produce them through precision die-casting technology.

Thermal Management of Charging Infrastructure

Heat Generation of Power Devices: Power devices in charging infrastructure, such as Insulated Gate Bipolar Transistors (IGBTs), will generate a large amount of heat during operation. With the continuous increase of charging power, the heat generation of IGBTs has increased significantly, from 1.2 kW in the past to 12.5 kW, posing a great challenge to heat dissipation.

-Influence of Environmental Factors: Charging infrastructure is usually located outdoors and will be affected by environmental factors such as direct sunlight, wind, and rain. Solar radiation heating will increase the temperature inside the charger housing, affecting the charging efficiency and the service life of the equipment. Extreme weather conditions may cause the charging infrastructure to malfunct. What is the liquid cold plate coolging for IGBTs?

- Wha is the heat sink cooling for IGBTs?

- What is a car battery module tray?

- How to produce a battery module tray?