Choosing between copper and aluminum for a heatsink is more than a materials decision—it affects thermal efficiency, weight, and cost. For engineers and builders designing power electronics, EV systems, or high-performance computing modules, that choice defines how well heat is transferred, managed, and maintained over time.

This guide examines the core physics of copper vs aluminum heatsinks, explores their thermal conductivity showdown, and explains when hybrid designs deliver the best results. Together, these sections help you select the right material strategy for your performance, budget, and reliability targets in 2025 and beyond.

The Core Physics: “The Sponge” vs. “The Radiator”

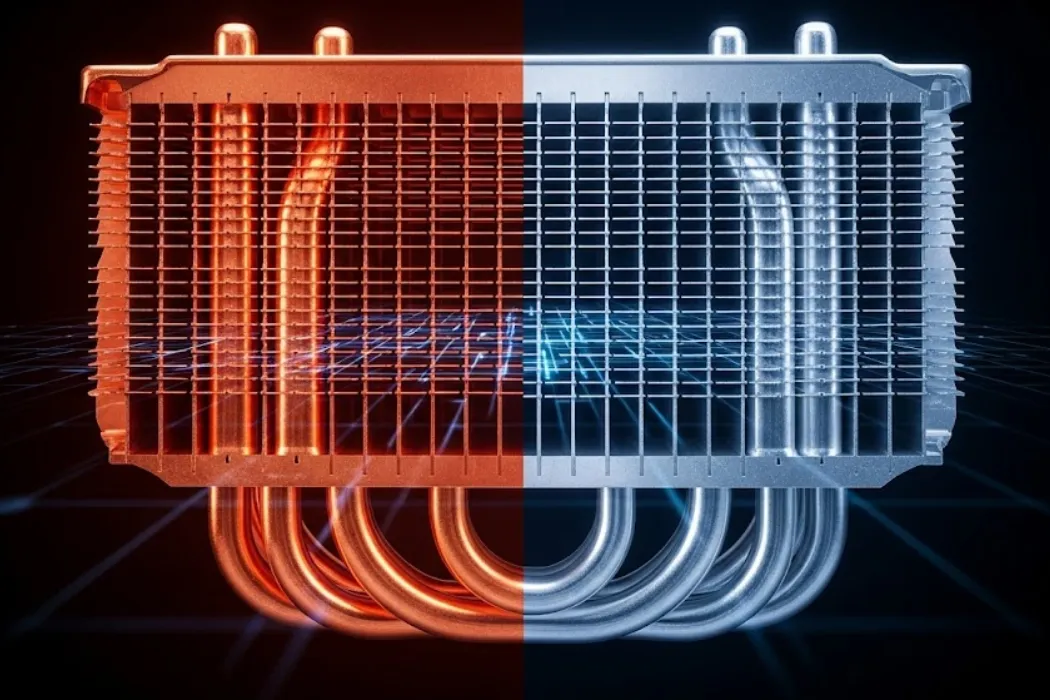

The analogy compares copper heatsinks to “The Sponge” due to their high thermal conductivity and ability to absorb heat quickly, while aluminum heatsinks function as “The Radiator”, efficiently dispersing heat over a larger surface area despite lower conductivity.

In thermal design, engineers often describe the performance of heatsink materials using intuitive metaphors that connect with real-world behavior. The models of “The Sponge” and “The Radiator” capture how heat moves through copper and aluminum, revealing the balance between fast heat absorption and broad heat dissipation.

Understanding the Metaphor: ‘The Sponge’ vs. ‘The Radiator’

“The Sponge” refers to copper heatsinks, which quickly soak up thermal energy just like a sponge absorbs water. This comes from copper’s very high thermal conductivity, allowing it to react almost immediately to temperature changes at a component’s interface.

“The Radiator,” on the other hand, reflects aluminum’s strength in spreading heat outward. Its lower conductivity compared to copper is offset by its ability to extend that heat over a larger surface area, making it more efficient at cooling distributed systems.

Together, these metaphors explain the fundamental trade-off designers face—rapid heat uptake versus efficient dissipation—and why both metals remain vital in modern cooling systems.

Comparing Thermal Properties: Copper vs. Aluminum

When choosing between copper and aluminum heatsinks, their physical and thermal characteristics influence not only performance but also weight and cost. The table below outlines the main comparison points critical to thermal engineers and product designers.

| Property | Copper 🧱 | Aluminum 🔩 | Notes |

|---|---|---|---|

| Thermal Conductivity | ~400 W/m·K ✅ | ~230 W/m·K ⚠️ | Copper transfers heat faster, enabling rapid absorption. |

| Density | 8.96 g/cm³ ⚠️ | 2.7 g/cm³ ✅ | Aluminum is significantly lighter, offering design flexibility. |

| Cost | Higher 💰 | Lower 💡 | Copper’s cost is balanced by performance; aluminum is more economical. |

| Thermal Role | Acts as a heat “sponge” ✅ | Acts as a “radiator” ✅ | Combining both can enhance overall thermal performance. |

In our experience, these physical properties not only affect heatsink performance but also influence manufacturability. For systems where speed of heat transfer is crucial—such as power electronics or processor modules—copper’s “sponge behavior” makes it valuable. For lighter devices or systems needing wide-spread dissipation, aluminum’s “radiator behavior” is a better fit.

Implications for Thermal Management Solutions

These material characteristics directly shape thermal management design strategies. Choosing one over the other depends on cooling goals, available space, and weight constraints.

- ✅ Copper suits compact assemblies that require rapid heat uptake and localized cooling efficiency.

- ✅ Aluminum fits lightweight systems where broad heat spreading and cost control matter most.

- 💡 System-level results depend on how heat sink geometry, airflow, and interface materials align with the selected metal.

- 🚀 Many solutions now integrate both—using copper heat pipes or cores with aluminum fins—to combine fast heat absorption and wide radiation surfaces.

At Walmate Thermal, our engineers apply this copper vs aluminum heatsink knowledge when designing thermal modules across industries like eMobility, AI cooling, and power electronics. By blending these two “behaviors,” we build heat management systems that achieve precise temperature control and long-term reliability across complex applications.

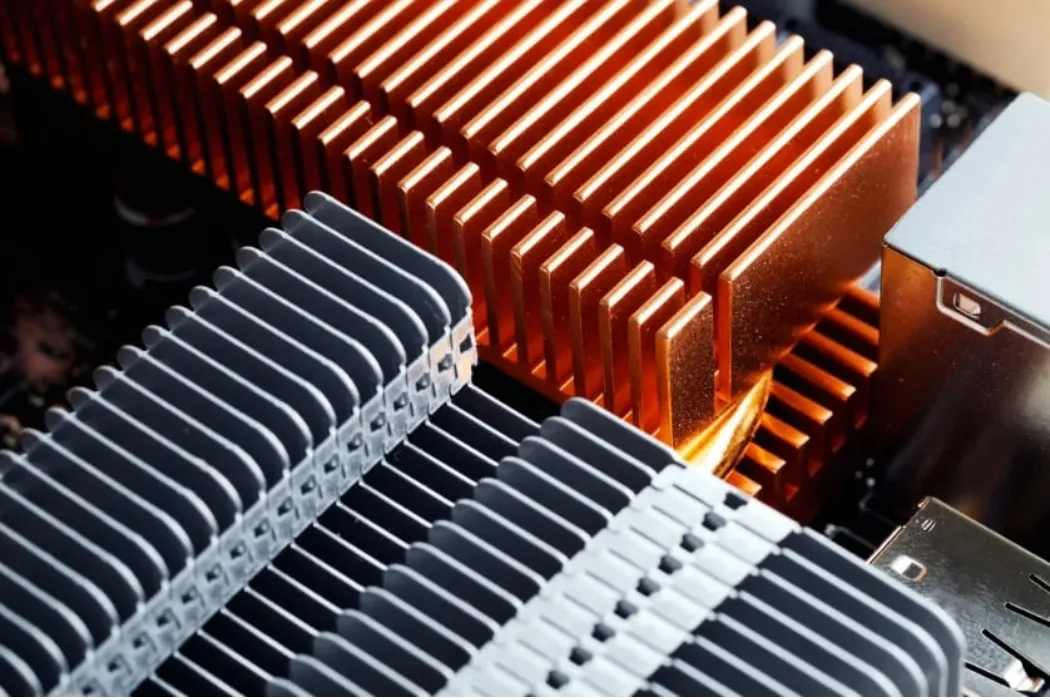

Copper: Fast Absorption, Heavy Weight, High Cost

Copper heatsinks offer excellent thermal conductivity for fast heat dissipation but tend to be heavier and more expensive compared to alternative materials like aluminum. These trade-offs affect their use in industries requiring efficient cooling with weight and cost constraints.

In our experience at Walmate Thermal, copper stands out for its superior heat conduction among metals used in thermal management. The following sections break down how its properties impact heatsink design choices for engineers and system builders evaluating copper vs aluminum heatsink performance.

Thermal Conductivity and Heat Dissipation Efficiency

Copper boasts a thermal conductivity of about 400 W/m·K, which is significantly higher than aluminum’s roughly 235 W/m·K. This intrinsic advantage allows copper heatsinks to draw heat away from components quickly and spread it evenly across their surface.

The result is faster temperature stabilization and improved cooling performance in high-power settings such as inverters, EV battery modules, or data center processors. These systems rely on efficient heat transfer to safeguard electronic reliability and extend service life. Walmate applies this through precision-engineered copper base plates and fins, ensuring optimal contact with heat sources.

| Material | Thermal Conductivity (W/m·K) | Efficiency Indicator |

| Copper | ~400 | 🚀 Excellent |

| Aluminum | ~235 | ✅ Good |

Weight Considerations and Mechanical Properties

Copper is dense—about 8.96 g/cm³—while aluminum sits at only 2.7 g/cm³. This means copper heatsinks weigh nearly three times more, posing challenges when weight reduction is a design priority.

For portable devices, drones, or automotive systems, the higher mass can limit practicality. Yet the same property can be a benefit in stationary or rugged applications where durability matters. Copper’s mechanical strength and natural corrosion resistance ensure stable structure and long service life for industrial-grade heatsinks.

| Material | Density (g/cm³) | Weight Suitability |

| Copper | 8.96 | ⚠️ Heavy – Not ideal for lightweight systems |

| Aluminum | 2.7 | ✅ Light – Suitable for portable designs |

Cost Analysis of Copper Versus Aluminum Heatsinks

The financial side of the comparison is straightforward: copper costs significantly more than aluminum. Between raw material prices and the added expense of working the metal, copper heatsinks represent a higher investment overall.

- 💡 Copper’s raw material price is higher, influencing total component cost.

- ⚙️ Manufacturing copper is more complex due to greater hardness and machining effort.

- ✅ The higher performance justifies use where superior heat dissipation is essential.

For most mass-produced consumer electronics, the cost differential pushes engineers toward aluminum. In contrast, Walmate’s custom copper heatsinks are favored in heavy-duty sectors like power converters, EV systems, and high-density servers where performance outweighs budget constraints.

Balancing Performance, Weight, and Cost in Application

Engineers rarely choose a single property over all others. They evaluate copper’s high thermal advantage against its weight and price according to system requirements. Walmate experts often support clients through this process to balance cooling efficiency and economic feasibility.

- ✅ High-power electronics, motors, or EV batteries—benefit from copper for consistent thermal control.

- ⚠️ Consumer handheld or lightweight systems—favor aluminum for cost and weight savings.

- 💡 Mixed-material designs (e.g., copper base + aluminum fins) offer a smart middle ground.

In professional practice, this balanced selection ensures the optimal compromise between heat transfer capability and mechanical practicality. Walmate Thermal specializes in designing such hybrid systems to meet performance and efficiency needs across industries from automotive to renewable energy systems.

Aluminum: Fast Dissipation, Lightweight, Budget-Friendly

Aluminum heatsinks offer fast heat dissipation, are approximately three times lighter than copper, and are significantly more budget-friendly, making them the preferred choice for applications where weight and cost are critical considerations.

In our experience at Walmate Thermal, aluminum remains one of the most practical materials for effective heat management. Its mix of high thermal diffusivity, corrosion resistance, and low cost allows engineers to design efficient and durable cooling systems without compromising mechanical integrity.

Thermal and Physical Properties of Aluminum

Understanding how aluminum compares with copper helps engineers choose the right heatsink material. Aluminum provides solid heat conductivity while being much lighter and easier to machine.

| Property | Aluminum ⚙️ | Copper 🔩 | Comparison 💡 |

|---|---|---|---|

| Thermal Conductivity | 160–220 W/(m·K) (pure aluminum ~237 W/(m·K)) | 398 W/(m·K) | ❌ Copper conducts more heat |

| Density | 2.7 g/cm³ | 8.96 g/cm³ | ✅ Aluminum is ~3× lighter |

| Specific Heat Capacity | 0.9 J/g·K | 0.385 J/g·K | ✅ Aluminum absorbs more heat before rising in temperature |

| Surface Emissivity (Black Anodized) | 🚀 Up to 8–10× higher than raw aluminum | N/A | ✅ Enhanced radiative cooling |

| Corrosion Resistance | ✅ Forms natural oxide layer | ⚠️ Prone to oxidation | Aluminum more durable in outdoor use |

| Ease of Machining | ✅ Softer and easier to machine | ❌ Harder and costlier to process | Lower fabrication cost with aluminum |

These properties show why aluminum heatsinks are preferred for applications balancing performance, weight, and production cost, such as in EVs, lighting, and power electronics.

Cost and Practical Advantages of Aluminum Heatsinks

Aluminum stands out for offering a favorable price-to-performance ratio. Compared with copper, it delivers effective dissipation at a much lower cost, which is key when scaling production for industries like consumer electronics or industrial control.

- 💰 Cost: Aluminum heatsinks are 3–5× cheaper than copper options in mass production.

- ⚖️ Weight Benefit: Its low density (2.7 g/cm³) helps manufacturers reduce product weight—important for portable and automotive designs.

- 🔧 Manufacturing Efficiency: Easier machining translates into faster production and reduced tooling wear, saving both time and cost.

- 🧩 Versatility: Alloys such as 6061-T6 and 6063-T5 offer good tensile strength and suitable thermal performance for various cooling geometries.

In our projects, these attributes often enable clients to maintain high performance while staying on budget—an essential factor in large-scale manufacturing environments.

Critical Perspective: When to Choose Aluminum vs. Copper

Choosing between these metals depends on the balance between thermal performance requirements and system constraints. Although copper provides higher raw conductivity, aluminum’s faster heat spreading efficiency (thanks to its high thermal diffusivity) and lower weight often make it the smarter option.

- ✅ Aluminum’s high diffusivity enables rapid heat transfer sufficient for most electronic systems.

- ⚠️ Black anodizing improves passive cooling efficiency but must be carefully managed to avoid overly thick coatings that could slightly reduce conductivity.

- 💡 For extreme thermal loads—like high-power amplifiers or dense server modules—copper still delivers the best heat transfer rate.

- 🚀 For mass-market products where every gram and dollar counts, aluminum remains unmatched for both practicality and performance.

Walmate Thermal applies these material insights in real-world cooling designs across EVs, power inverters, and LED lighting. Our engineers consider both thermal performance and economic value to guide clients toward the ideal aluminum or copper solution for each project.

Empower Your Innovations with Precision Thermal Solutions

Partner with Walmate Thermal’s expert team to customize advanced cooling systems that enhance performance and reliability across power electronics, EVs, and medical devices. Experience seamless integration from design to production backed by two decades of R&D leadership and cutting-edge manufacturing capacity.

Thermal Conductivity Showdown: 400 W/mK vs. 200 W/mK

Copper heatsinks, with a thermal conductivity around 400 W/mK, transfer heat nearly twice as efficiently as aluminum heatsinks, which have about 200 W/mK. Despite this advantage, aluminum is favored in many scenarios due to its lighter weight and lower cost.

When comparing copper vs aluminum heatsink options, engineers often look beyond thermal conductivity alone. Real-world adoption depends on balancing performance, weight, cost, and ease of manufacturing. Below is a closer evaluation of each material’s strengths and trade-offs.

Thermal and Physical Properties Comparison

This comparison helps visualize the key material differences that directly affect heatsink design and selection for specific applications.

| Property | Copper 🔥 | Aluminum ⚙️ | Comments |

|---|---|---|---|

| Thermal Conductivity | 386–401 W/mK | 200–230 W/mK | Copper conducts heat nearly twice as efficiently ✅ |

| Density | 8.96 g/cm³ | 2.7 g/cm³ | Aluminum is much lighter 🚀 |

| Weight (Equal Volume) | Heavier by about 3.3× | Lighter ✅ | Weight affects mechanical design ⚠️ |

| Thermal Resistance | ~0.02 K/W | Higher ❌ | Lower for copper, meaning better heat removal |

| Relative Cost | High 💸 | Low ✅ | Cost-sensitive designs prefer aluminum |

| Common Alloys | C101/C110 (~390 W/mK) | 6061 (151–201 W/mK), 6063 (201–218 W/mK) | Typical materials used for heatsinks |

For engineers, choosing between these materials often hinges on structural limitations, manufacturing process, and thermal requirements rather than conductivity alone.

Practical Insights and Trade-offs

Real-world heat management rarely depends on conductivity figures in isolation. Each setup combines geometry, airflow, and interface quality, influencing overall performance.

- ✅ Copper offers superior heat transfer and can cut thermal resistance by roughly 50% compared to aluminum, making it suitable for high-power and confined-space applications.

- ⚠️ Its high density makes copper heatsinks significantly heavier, often unsuitable for weight-sensitive uses in laptops or aerospace components.

- ❌ Copper also comes with greater machining difficulty and cost, adding complexity in volume manufacturing.

- ✅ Aluminum delivers effective cooling at about half the conductivity of copper while staying much lighter, more affordable, and corrosion-resistant.

- 💡 Thermal conductivity alone doesn’t double the cooling performance; factors like heatsink geometry, forced-air cooling, and TIM quality matter equally.

- 🚀 Hybrid solutions—such as copper bases bonded to aluminum fins—combine high thermal transfer with reduced weight and cost, a method Walmate Thermal often applies in system-level cooling designs.

In our experience at Walmate Thermal, final material selection depends on target thermal resistance, available mechanical space, and cost constraints. Engineers frequently blend copper and aluminum elements to reach optimal results across power electronics, EVs, and industrial automation systems.

The Corrosion Factor: Why You Can’t Always Mix Them (Galvanic Corrosion)

Galvanic corrosion occurs when copper and aluminum are directly connected in the presence of an electrolyte, causing the aluminum (anode) to corrode rapidly while the copper (cathode) remains protected. This is why mixing these metals in heatsink assemblies without proper isolation can lead to premature failure of the aluminum component.

When designing or assembling a copper vs aluminum heatsink, galvanic corrosion becomes a key factor. The interaction between these metals can significantly impact the durability and efficiency of thermal management systems if not properly controlled.

Understanding Galvanic Corrosion

Galvanic corrosion happens when two dissimilar metals, such as copper and aluminum, are in electrical contact in the presence of an electrolyte like water or humidity. The aluminum acts as the anode and corrodes, while copper remains protected as the cathode.

The phenomenon is based on their position in the electrochemical series—since aluminum is less noble than copper, it sacrifices itself to protect the copper surface. The effect becomes more aggressive in humid environments or where condensation frequently forms.

- ⚠️ Happens when dissimilar metals are connected with an electrolyte present.

- ⚠️ Aluminum serves as the anode and corrodes faster.

- ⚠️ Moisture or condensation accelerates the corrosion effect.

Key Data on Corrosion Rates and Influencing Factors

When copper and aluminum are paired in a conductive and moist environment, aluminum’s corrosion rate can increase from 10× to as high as 100× compared to when it is used alone. This makes the material pairing critical in high-performance cooling systems.

| ⚙️ Condition | 💡 Impact on Aluminum | ✅ Copper Effect |

|---|---|---|

| Direct contact with copper in humid air | Corrosion rate increases up to 100× | Remains protected |

| Smaller aluminum surface area relative to copper | Higher current density, faster material loss | Stable interface |

| Exposure to seawater | Deterioration can occur within months | Unaffected |

These figures highlight the importance of material selection and surface design. Even with minor moisture exposure, the difference in potential between copper and aluminum can drive rapid material degradation.

Critical Perspective and Common Misconceptions

Many assume that metals sharing mechanical strength or thermal performance can be joined safely, but electrochemical compatibility matters more. Moisture—especially condensation—can trigger galvanic reactions that rapidly degrade aluminum when paired with copper.

- ❌ Using metals with similar physical strength does not guarantee corrosion compatibility.

- ⚠️ Even minor humidity can initiate galvanic corrosion.

- 💡 Use dielectric barriers, insulating gaskets, or chemical coatings to break the galvanic circuit.

- ✅ Choosing metals closer on the galvanic series helps reduce risk in humid or outdoor conditions.

Preventing Galvanic Corrosion in Thermal Management Applications

In heatsink assemblies, preventing galvanic corrosion requires careful engineering decisions. In our experience working with thermal systems, preventive design and material isolation are the most effective steps.

- 💡 Add dielectric barriers or insulating coatings between copper and aluminum components.

- ⚙️ Avoid design ratios where the aluminum anode area is much smaller than the copper cathode area.

- ✅ Choose alloys or metals positioned closer in the galvanic series when direct contact cannot be avoided.

- ⚠️ Assess environmental conditions—especially humidity and condensation—and apply suitable protection.

- 🔍 Schedule regular inspections to detect corrosion early and extend component life.

For engineers designing high-reliability systems, understanding and managing galvanic corrosion can mean the difference between long-term stability and costly failure. Companies like Walmate Thermal integrate these principles into their 20 years of experience in designing copper vs aluminum heatsinks and other advanced cooling solutions for EVs, power electronics, and industrial systems.

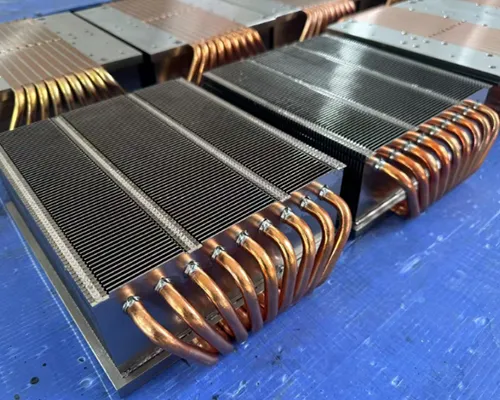

Hybrid Designs: Why the Best Coolers Use Both Metals

Hybrid cooler designs combine metal and plastic elements to balance durability, stability, and cost-effectiveness, offering superior performance compared to single-material alternatives for most cooling applications. They leverage the strength and thermal properties of metals while maintaining the affordability and lighter weight of plastics.

In our experience at Walmate Thermal, the most efficient coolers balance strength, heat transfer, and lightweight construction. Hybrid designs make this possible by integrating both metallic and polymer elements, producing coolers that meet industrial, automotive, and consumer-grade performance demands.

Performance Comparison of Plastic, Metal, and Hybrid Coolers

Plastic, metal, and hybrid coolers each serve different engineering needs, but hybrid assemblies often deliver the most practical balance between cost, weight, and function. The table below outlines their comparative characteristics across key metrics.

| Attribute | Plastic | Metal | Hybrid |

|---|---|---|---|

| Durability | ⚠️ Moderate | ✅ High (especially aluminum) | ✅ High |

| Stability | ❌ Lower | ✅ Excellent | ✅ Moderate–High |

| Weight | ✅ Light | ⚠️ Heavy | ✅ Moderate (lighter than pure metal) |

| Cost | ✅ Low | ❌ High | ⚠️ Mid-range |

| Aesthetics | ⚙️ Modern/basic | 🎨 Classic/sleek | 🚀 Modern + Sophisticated |

| Rust Susceptibility | ✅ None | ⚠️ Possible if unmaintained | ✅ Reduced |

| Best Use Case | 💡 Portability and affordability | ⚙️ Large exhaust fans, durability | 🚀 Balanced performance |

Why Hybrid Designs Are Optimal for Most Applications

Engineering teams often face trade-offs among durability, weight, and cost when selecting cooler materials. Metal assemblies deliver exceptional strength and conductivity but add weight and expense. Plastic variants, while lightweight and inexpensive, struggle with deformation in high-thermal environments.

Hybrid cooling systems solve this by combining metallic cores or fins with polymer housings or covers. This configuration enhances heat dissipation and reduces weight at a lower cost than a full-metal alternative. In high-performance segments like aerospace, EVs, and power conversion, hybrid structures strike the right balance between strength, mass, and conduction efficiency.

Thermal Efficiency and Real-World Applications of Hybrid Cooling

Walmate Thermal integrates hybrid approaches in its system-level thermal management solutions, especially where strength-to-weight ratios matter. These assemblies deliver superior energy efficiency and resist mechanical stress across wide temperature ranges, ensuring consistent performance in harsh environments.

- 🚀 Support high temperatures and pressures in automotive and aerospace cooling loops.

- 💡 Improve production throughput by using fluted conformal channels with high-conductivity metal inserts.

- ✅ Resist corrosion for extended service life in industrial and building cooling systems.

Engineers selecting hybrid architectures benefit from improved thermal conduction—similar to high-grade aluminum heatsinks—while retaining the affordability of composite housings. When considering copper vs aluminum heatsink applications, hybrid designs often present a middle path by blending these metals’ best traits within lightweight frameworks, a strategy proven in Walmate Thermal’s multi-industry solutions.

The Garage Guru’s Verdict: When to Pay for Copper

Copper heatsinks are worth paying for when maximum thermal conductivity and heat dissipation are critical, such as in high-performance CPUs, GPUs, or compact electronics where space limits airflow and cooling options. In most standard or cost-sensitive applications, aluminum heatsinks offer sufficient performance at a significantly lower price.

When comparing copper vs aluminum heatsinks, the trade-off often comes down to performance versus cost. In our experience at Walmate Thermal, engineers choose copper only when every degree of temperature matters to system reliability or performance.

Key Thermal and Material Comparisons

The data below outlines how copper and aluminum differ in key physical and thermal properties. These differences explain the price gap and their specific use cases.

| Property | Copper ⚙️ | Aluminum ⚙️ |

|---|---|---|

| Thermal Conductivity | 385–400 W/m·K ✅ | 205–235 W/m·K ⚠️ |

| Density | 8.96 g/cm³ ⚠️ (Heavier) | 2.70 g/cm³ ✅ (Lighter) |

| Material Cost (2026 Estimate) | $8,600–$9,200/ton ⚠️ | $2,200–$2,400/ton ✅ |

| Typical Price per Heatsink | $10–$25 ⚠️ | $2–$8 ✅ |

| Weight (100mm × 100mm × 25mm block) | ~2.24 kg ⚠️ | ~0.67 kg ✅ |

| Corrosion Resistance | Requires coating to prevent tarnish ⚠️ | Forms protective oxide layer ✅ |

| Machinability | Difficult and costlier ⚠️ | Easier and cheaper ✅ |

| Heat Dissipation Efficiency | Dissipates heat 30–50% faster 🚀 | Adequate for most uses ⚙️ |

These data points show how copper excels in moving heat, while aluminum offers an unbeatable balance of weight and cost-efficiency. Selecting the right one depends on your thermal margin and design priorities.

Critical Perspective on When to Choose Copper

Copper is most justified when the system operates near its thermal limits. This includes overclocked CPUs, power electronics, and tightly enclosed assemblies with restricted ventilation.

- ✅ Thermal advantage: Copper’s higher conductivity prevents overheating and avoids thermal throttling under heavy loads.

- ⚠️ Cost concern: It costs 3–4× more than aluminum and adds considerable weight.

- ⚙️ Manufacturing challenge: Harder to machine and less practical for large, lightweight devices.

- 💡 Hybrid design tip: Many engineers use copper bases for rapid heat absorption, paired with aluminum fins for efficient airflow cooling.

- 🚀 Performance threshold: The real benefit appears only when airflow is the limiting factor, making copper’s efficiency worth the extra investment.

In most standard cooling situations—like moderate-load CPUs, LED systems, or inverter housings—Walmate Thermal recommends aluminum or hybrid solutions. They are easier to produce, lighter for installation, and deliver stable heat performance across varied environments.

For applications where failure or throttling risk is unacceptable, our engineering team can design a copper or composite heatsink tailored to your operating profile and mechanical constraints.

FAQs: About Copper vs. Aluminum Heatsinks

Is a copper heatsink always better?

Copper has a higher thermal conductivity of around 400 W/m·K compared to aluminum’s 205 W/m·K, so it transfers heat more efficiently. But that doesn’t mean it’s always the better option.

In our experience at Walmate Thermal, the right choice depends on the system design, heat load, and cost target. Copper excels in compact, high-performance designs, while aluminum often offers the best thermal-to-weight efficiency for large cooling surfaces.

Why are most heatsinks made of aluminum?

Aluminum offers a balance of performance, weight, and cost that suits most thermal applications. It’s easy to extrude into complex fin structures and provides good thermal conductivity for the majority of power densities.

Walmate Thermal often uses 6061 or 6063 aluminum alloys because they combine strong thermal properties with excellent machinability and corrosion resistance, especially in industrial and automotive systems.

Does copper corrode faster than aluminum?

Copper is more prone to oxidation in humid or chemically reactive environments, while aluminum forms a stable oxide layer that protects it naturally. Without surface treatment, copper can develop patina over time that slightly reduces its thermal performance.

To prevent that, Walmate Thermal uses nickel plating or protective coatings on copper heatsinks used in high-moisture or industrial environments.

What is the weight difference between copper and aluminum?

Copper is roughly 3 times heavier than aluminum. Its density is about 8.96 g/cm³, while aluminum’s is around 2.7 g/cm³. That’s a major consideration in designs where total weight affects mechanical stability or mobility.

In eMobility and energy applications, Walmate engineers frequently choose aluminum heatsinks to improve efficiency and reduce mounting load without sacrificing cooling performance.

Can you mix copper and aluminum in a loop?

Mixing copper and aluminum in a single cooling loop can cause galvanic corrosion if coolant conductivity isn’t properly controlled. This happens because of the potential difference between the two metals.

When combining them, Walmate Thermal recommends using corrosion inhibitors, dielectric coolants, or separating metals with barrier fittings to extend loop lifespan and maintain cooling efficiency.

Final Thoughts

Engineers weighing copper against aluminum in heatsink design face a trade‑off between performance, weight, and cost. Copper excels at heat absorption and stability under heavy thermal loads, while aluminum wins on lightness, affordability, and corrosion resistance. Both materials have specific strengths depending on environment, cooling geometry, and mechanical constraints—and hybrid systems often merge their best traits for balanced results.

By aligning material selection with performance goals and budget realities, teams can improve reliability and product efficiency without overspending. Working with a trusted thermal solutions partner like Walmate Thermal streamlines this decision, helping convert these technical insights into practical, high‑efficiency cooling systems tailored to demanding applications from EV power modules to industrial electronics.