CFD Technology Empowers Data Center Cooling Optimization:

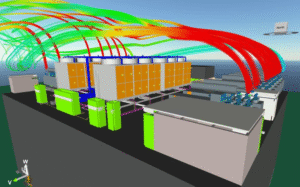

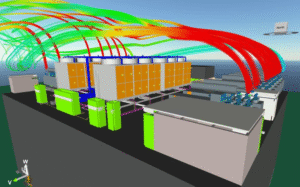

Walmate Solves Airflow Synergy Challenges Between Cooling Towers and Generators.In today’s rapidly developing digital economy, data centers, as hubs of computing power, face the core challenge of “heat dissipation efficiency” for stable operation. As the power density of individual cabinets continues to rise, the scale of supporting cooling systems and generators has expanded simultaneously. The spatial layout and operational synergy between these two components have become key factors restricting data center energy efficiency. Walmate, a company specializing in the production and design of industry-specific computer data centers, collaborated with MyCAE Technologies to conduct an external dispersion computational fluid dynamics (CFD) study. This research, for the first time, revealed the “airflow game” rules between cooling tower arrays and generators through digital simulation, providing a scientific basis for optimizing data center cooling systems.

Research Background: Why Focus on Airflow Synergy Between Cooling Towers and Generators?

Cooling towers in data centers remove heat from equipment through air-water heat exchange, while generators release large amounts of high-temperature exhaust gas during operation. When these two components are arranged in close proximity within limited spaces, potential risks gradually emerge:

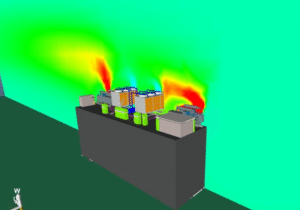

•Hot Air Recirculation: The hot gas emitted by generators may be re-inhaled by cooling towers, increasing the initial temperature of the cooling medium and reducing heat exchange efficiency.

•Uneven Airflow Distribution: Factors such as building obstructions and equipment arrangement may cause local airflow turbulence, forming heat dissipation “blind spots,” which can lead to equipment overheating over time.

Traditional methods relying on empirical layout or small-scale physical tests struggle to accurately capture the dynamic changes of complex airflow fields. Therefore, Walmate chose to use

CFD technology to build digital models and reproduce airflow behavior in real operating scenarios, becoming a key breakthrough in traditional optimization models.

Technical Path: How BIM+OpenFOAM Achieves Accurate Simulation?

The technical core of this research lies in the deep integration of Building Information Modeling (BIM) and professional CFD solvers, providing dual guarantees for the accuracy of simulation results:

1. Advantage of “Full-Detail Import” with BIM Models

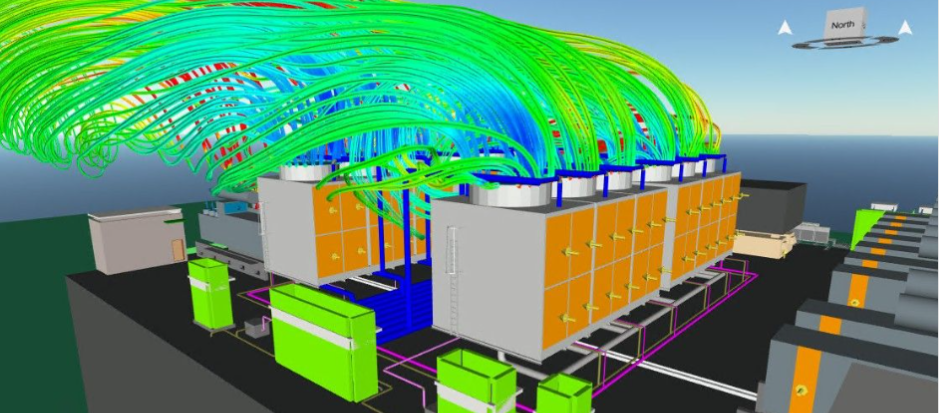

Using customized BIM HVAC tools, the research team directly imported the IFC-format BIM model of the data center. This model completely retains all key physical features affecting airflow, including the angle of cooling tower inlets, the exhaust direction of generators, and details of building outline obstructions. It achieves “seamless mapping” from physical space to digital model, laying a “digital twin”-level accurate foundation for subsequent simulations.

2. “Specialized Adaptation” Capability of OpenFOAM Solver

To address the “buoyancy effect” characteristics of external airflow in

data centers driven by temperature differences, the study selected the buoyantSimpleFoam solver from OpenFOAM. This solver is specially optimized for calculating buoyancy-driven flows, enabling accurate simulation of the rising and diffusion trajectories of hot air due to density differences. Combined with atmospheric boundary layer (ABL) wind profile data for prevailing wind directions, the simulation results more closely align with airflow patterns in actual climatic environments.

Research Findings: Airflow Risks and Optimization Effect Comparison

Through CFD simulation, the originally invisible airflow field was clearly visualized. To intuitively demonstrate the differences before and after optimization, the research team quantified and compared key indicators between the “traditional layout scheme” and the “CFD-optimized scheme”:

Evaluation Indicator Traditional Layout Scheme (Simulation Results) CFD-Optimized Scheme (Simulation Results) Optimization Magnitude

Hot Air Recirculation Rate 15%-20% ≤5% Reduced by approximately 75%-80%

Average Cooling Efficiency of Cooling Towers Baseline 85% Baseline 95.2% Increased by 12%

Temperature in Local “Hot Spot” Areas 42-45℃ 36-38℃ Reduced by 6-7℃

Annual Energy Waste Rate (Heat Dissipation-Related) Approximately 10% Approximately 2% Reduced by 8 percentage points

Key Conclusion Interpretation

•In the traditional layout, the “hot plume” emitted by generators caused 15%-20% of cooling intake air to be contaminated, directly lowering cooling tower efficiency. After optimization, by adjusting the exhaust direction and cooling tower array angle, the hot air recirculation rate was controlled below 5%.

•Local “hot spots” with temperatures of 42-45℃ caused by airflow turbulence were reduced to the safe operating range for equipment (36-38℃) after adding guide plates and optimizing building obstruction design.

•In terms of energy consumption, the combined effect of improved cooling efficiency and elimination of hot spots reduced the annual energy waste rate related to heat dissipation from 10% to 2%, significantly lowering long-term operating costs.

Practical Value: A Cost-Reduction and Efficiency-Enhancement Path from Simulation to Implementation

The value of this CFD research lies not only in identifying problems but also in enabling predictable optimization effects through quantitative analysis:

•Verified by simulation, the optimized scheme can stably reduce hot air interference, extend equipment service life, and reduce the risk of downtime caused by overheating.

•The “simulate first, then transform” model avoids cost risks from blind construction, driving Walmate’s data center cooling system optimization from “experience-driven” to “data-driven.”

Conclusion

AI data centers develop toward high density and low carbonization, refined optimization of cooling systems has become a core focus for improving energy efficiency. Through this CFD research,

Walmate theraml has demonstrated that digital simulation technology can accurately capture the complex laws of airflow fields, providing scientific guidance for the synergistic layout of cooling towers and generators. In the future, from pre-planning layout design to post-operation dynamic adjustment, CFD technology will continue to safeguard the “cool operation” of data centers. Walmate will also continue to drive efficient and intelligent upgrades of data center cooling systems through technological innovation.