Beyond Heat Pipes: Welcome to the Vapor Chamber

As GPUs and laptops grow thinner and more powerful, conventional heat pipes struggle to keep up with rising heat density. Engineers and enthusiasts now face the challenge of achieving superior thermal performance without increasing bulk or power draw—making vapor chambers the next frontier in compact, high-efficiency cooling.

This guide explores how vapor chambers work compared to traditional heat pipes, where each technology fits best in GPUs and laptops, and what cost-performance tradeoffs determine the future of cooling innovation.

Beyond Heat Pipes: Welcome to the Vapor Chamber

Vapor chambers offer a major upgrade from traditional heat pipes by delivering superior heat distribution over larger areas with ultra-thin profiles, achieving thermal conductivity 3–5 times higher than heat pipes, though at a 30–50% higher cost.

The evolution of cooling technologies has shifted from traditional tubular heat pipes to flat vapor chambers that enable efficient heat spreading across tight spaces. These changes impact both performance and manufacturing methods used in systems like GPUs and laptops that face higher thermal loads.

Key Performance Comparison

| Metric | Heat Pipes | Vapor Chambers | Performance Indicator |

|---|---|---|---|

| Thermal Conductivity | 400–50,000 W/m·K (effective) | 1,500–100,000 W/m·K (theoretical max) | 🚀 Higher uniformity |

| Maximum Heat Load | ~125W (horizontal) | Up to 450W | 🚀 Greater thermal handling |

| Optimal Power Density | Below 25 W/cm² | Up to 50 W/cm² | ✅ Better for high flux |

| Profile Thickness | Tubular, limited flattening | As thin as 0.3mm | 💡 Ideal for compact devices |

| Cost Difference | Baseline | +30–50% | ⚠️ Higher manufacturing cost |

| Heat Transfer Distance | Best beyond 50mm | Localized spreading | ✅ Better for concentrated loads |

| Thermal Resistance & Weight | Higher, heavier copper spreaders | Lighter and lower resistance | 🚀 Enhanced cooling efficiency |

Technological and Manufacturing Insights

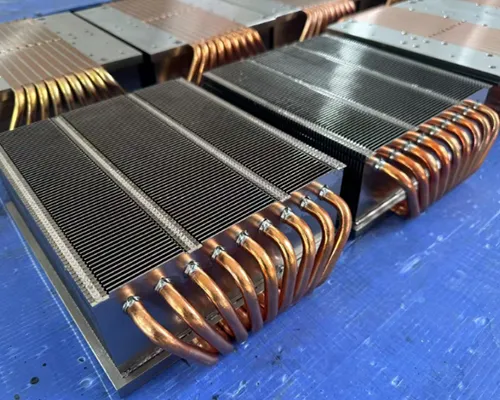

In our experience, vapor chambers represent a structural leap from linear heat transport to planar heat distribution. This shift allows even heat spreading across multiple dense components, reducing hot spots in GPUs and CPUs.

- 💡 Ultra-thin vapor chambers eliminate internal flow restrictions common in bent or flattened heat pipes, maintaining thermal performance.

- ⚠️ The manufacturing process demands strict tolerances and heightened control, making vapor chambers more defect-sensitive and costlier.

- ✅ Heat pipes remain suitable for longer heat transfer distances or devices that operate under changing orientations.

- 🚀 Hybrid solutions are emerging that integrate phase-change materials, lowering junction temperatures by up to 15°C while optimizing cost and performance.

Application Considerations and Market Trends

Vapor chambers and heat pipes both serve critical roles depending on the system’s size, heat density, and cost targets. The market shows a noticeable tilt toward vapor chambers as systems grow thinner and more powerful.

- ✅ Vapor chambers excel in compact form factors and high heat flux zones like modern GPUs, CPUs, and high-performance servers.

- 💡 Heat pipes are typically used in cost-sensitive or distributed systems where distance and orientation flexibility matter most.

- 🚀 As costs decrease through manufacturing scale, vapor chambers are set to become the default option for premium cooling designs.

- ⚠️ Heat pipes still dominate applications requiring broad or directional heat movement across larger assemblies.

- ✅ For B2B system integrators, selecting the right technology depends on balancing budget with thermal density requirements.

At Walmate Thermal, our engineering team leverages nearly 20 years of cooling expertise to design application-specific heat dissipation systems. Whether using advanced vapor chambers or robust heat pipe solutions, we tailor each design around performance goals, structural form, and long-term reliability.

How It Works: The “Flat Heat Pipe” Concept Explained

The “flat heat pipe” (also called a vapor chamber) is a two-dimensional heat transfer device that uses phase change of a working fluid to rapidly spread heat across a broad, flat surface, enabling highly efficient, near-isothermal cooling for compact electronics like GPUs and laptops.

Flat heat pipes, often called vapor chambers, enable fast and uniform heat distribution across a surface. By using a simple yet powerful phase-change process, they help maintain stable operation of high-density electronics while keeping compact designs cool and lightweight.

What is a Flat Heat Pipe?

A flat heat pipe, sometimes referred to as a vapor chamber, is designed to spread heat evenly over a broad surface. Inside the sealed metal enclosure lies a working fluid that evaporates at the heat source and condenses at the cooler region.

The condensed liquid travels back via a wick structure, completing the cycle. This creates continuous two-phase heat transfer that moves thermal energy with minimal temperature difference, resulting in near-isothermal performance across the entire plate.

Key Technical Specifications and Materials

| 📏 Specification / Material | ⚙️ Details |

|---|---|

| Thickness | 1.0 mm typical, slightly thicker than a credit card |

| Heat Transfer Capacity | Example: a 1-inch diameter, 2-foot long pipe can transfer 3.7 kW at 980°C with only a 10°C drop |

| Maximum Heat Flux | Exceeds 23 kW/cm² |

| Example Dimensions | 1.22 m long × 30.48 cm wide × 1.27 cm thick |

| Typical Materials | Monel 400 (nickel-copper alloy), copper, aluminum |

| Working Fluids | Water for low temperatures, liquid metals for high temperature use |

Advantages of Flat Heat Pipes Compared to Cylindrical Pipes

- ✅ Flat geometry provides a larger surface area-to-volume ratio than traditional cylindrical pipes.

- ✅ Enables two-dimensional heat spreading, ideal for compact designs like GPUs, CPUs, and laptops.

- ✅ Supports ultra-thin cooling solutions down to just 1 mm, fitting into slim enclosures.

- ✅ Maintains near-isothermal conditions across a surface, reducing temperature differences that can damage components.

- ✅ Can be embedded into heat sink bases or vapor plates for uniform thermal distribution.

Considerations and Challenges in Design and Integration

- ⚠️ Performance depends heavily on precise wicks and accurate fluid filling during manufacturing.

- ⚠️ Material choice—such as Monel 400 or copper—affects capillary performance and longevity, preventing dry-out issues.

- ❌ Flat vapor chambers can be more expensive and complex to fabricate than cylindrical pipes or standard heat sinks.

- ⚠️ Integration must be carefully managed to ensure consistent contact with the heat source and avoid reliability risks.

- 💡 Experts recommend vapor chambers for high heat flux applications where space is limited and performance cannot be compromised.

2D vs. 1D Cooling: The “Parking Lot” vs. The “Highway”

2D (vapor chamber/”parking lot”) cooling provides superior heat spreading and efficiency for high-density GPUs and laptops compared to 1D (heat pipe/”highway”) cooling, which is simpler but less effective at distributing heat across a surface. Vapor chambers enable better thermal management for modern, high-power chips, while heat pipes are cost-effective for lower power or smaller devices.

Both technologies serve the same goal—efficient heat dissipation—but they differ significantly in structure, performance, and applicability. The vapor chamber, acting as a 2D “parking lot,” spreads heat across a surface, while the heat pipe, acting as a 1D “highway,” transports heat along a linear path.

Technical Comparison of 2D and 1D Cooling Technologies

| Parameter | 2D Vapor Chamber 💨 | 1D Heat Pipe 🔄 |

|---|---|---|

| Heat Spreading Area | Up to 1000 cm² | ≤ 10 cm² |

| Typical Thickness | 0.3–2.0 mm | 2–8 mm |

| Max Heat Transport Capacity | 200–400 W | 10–100 W per pipe (multiple required for higher loads) |

| Thermal Conductivity | 10,000–120,000 W/m·K (isotropic) | 5,000–50,000 W/m·K (anisotropic) |

| Cost per Unit | 💡 $5–$20 | 💡 $1–$5 |

| Design Flexibility | ✅ High — supports thin and custom shapes | ⚠️ Moderate — limited to linear paths |

| Typical Use Cases | 🚀 High-power GPUs, gaming laptops, servers | ✅ Entry-level laptops, smartphones, compact devices |

From this comparison, it’s clear that vapor chambers excel in handling widespread and intensive thermal loads. They support higher power densities, thinner form factors, and even heat distribution. Heat pipes remain a solid choice for smaller or budget-sensitive designs.

Practical Insights and Critical Perspective

- 💡 Vapor chambers spread heat across a broad, flat surface—like cars parking side by side—enabling smooth dissipation from concentrated chip hotspots.

- ✅ They also make it easier to design thinner devices and use denser components without thermal throttling.

- ⚠️ Heat pipes act like one-way highways, moving heat along a pipe. They’re ideal for point-to-point paths but struggle with surface-wide loads.

- ❌ Using many heat pipes doesn’t replicate a vapor chamber’s uniform heat spreading ability, which matters in modern laptops and GPUs with tight layouts.

- 💡 In our experience, the right choice depends on the device’s power density, space constraints, and cost sensitivity.

- ✅ Vapor chambers deliver higher performance and better long-term efficiency, while heat pipes work best for low-power or cost-limited builds.

At Walmate Thermal, engineers often integrate vapor chamber technology into advanced GPU and AI cooling modules. This optimizes both performance and longevity while maintaining sleek, lightweight designs.

Elevate Your Product Performance with Precision Thermal Solutions

Partner with Walmate Thermal to unlock cutting-edge, customized thermal management backed by two decades of expertise and innovative R&D. Experience reliable, scalable solutions that boost efficiency and ensure peak operation across industries like electric vehicles, AI, and medical technology.

Where You Find Them: High-End GPUs and Laptops

High-end GPUs and gaming laptops are the main markets where vapor chamber cooling solutions are implemented. These devices, often priced above $1,000–$2,000, house flagship processors and graphics cards that produce significant heat, requiring advanced thermal management to sustain performance.

Vapor chamber technology appears most often in performance-oriented hardware where temperature balance directly determines stability. In our experience, the integration of these compact thermal modules is now standard practice for premium GPUs and gaming laptops that push beyond conventional cooling limits.

Market Segments Featuring Vapor Chamber Cooling

The gaming laptop market has seen rapid growth driven by high-performance demands. The segment is expected to reach $21.36 billion in 2025, with mainstream prices ranging from $1,000 to $2,000.

- 🚀 Key OEMs such as ASUS, MSI, Alienware, HP Omen, and Razer integrate vapor chamber systems with NVIDIA RTX 4060 to 5080 mobile GPUs.

- 💡 Gaming PCs and laptops together are projected to hit $62.36 billion by 2025.

- ✅ HP holds a 26.4% unit share, maintaining strong competition alongside Lenovo and Apple.

High-End GPU Integration and Thermal Demands

Premium gaming models with GPUs like the NVIDIA RTX 5080 generate more than 150W of heat. Without advanced cooling, sustained performance would be unreachable due to thermal throttling.

Vapor chamber cooling systems disperse heat quickly across the entire chamber surface. They balance load between components and chassis, allowing consistent clock speeds during intensive gaming or rendering workloads.

- ✅ Maintains stable performance and avoids throttling.

- 💡 Enables thin and quiet laptop designs while supporting high-refresh-rate OLED and mini-LED displays.

- 🚀 Reflects ongoing innovation in compact thermal architectures from leading brands.

Brand-Specific Usage and Market Positioning

Manufacturers differentiate their models through unique vapor chamber implementations. Each uses it to balance design, cooling, and brand identity.

- ✅ Alienware aims at flagship-grade performance with the m16 R2, custom cooling layouts, and NVIDIA’s top-tier laptop GPUs.

- 💡 HP Omen delivers a performance-to-price balance in the mid- to high-tier categories, represented by the Omen Max 16 featuring RTX 5080 mobile GPU.

- ✅ ASUS ROG and MSI focus on robust build quality, with average device prices above $636, emphasizing reliability under gaming loads.

- 💡 Razer positions its CNC-machined unibody notebooks as premium lifestyle devices supported by integrated ecosystems.

Market Trends and Regional Insights

The gaming laptop sector continues expanding at a compound annual growth rate of 4.77% through 2032, expected to reach $29.62 billion. This indicates strong and steady momentum in high-end cooling demand.

| 📊 Segment | Key Insight |

|---|---|

| 🚀 Premium ($2,000+) | Attracts enthusiasts investing in latest chips, AI processing, and display technologies. |

| 🌏 Asia-Pacific | Led by China, the region is the largest and most dynamic gaming laptop market globally. |

| 🎮 GPU Usage | NVIDIA RTX 4060 mobile GPU accounts for about 5% of active GPUs based on Steam data, showing cross-segment adoption. |

In our experience at Walmate Thermal, these trends underline a growing reliance on vapor chamber design within compact, performance-driven form factors. Advanced cooling integration ensures steady thermal efficiency—critical as GPUs and processors continue scaling in power density.

Vapor Chamber vs. Copper Block: Eliminating Hotspots

Vapor chambers outperform solid copper blocks in eliminating hotspots for surfaces larger than 40 mm due to superior two-dimensional heat spreading, while copper blocks are more effective for smaller contact areas and higher power densities below 500 W.

Vapor chambers and copper blocks are two of the most common solutions for managing high power density in modern electronics. Each has unique advantages depending on size, power, and design constraints. Below is a detailed look at how these two cooling technologies differ in performance and practical applications.

Performance Comparison Table

| Parameter | Vapor Chamber | Copper Block |

|---|---|---|

| Performance Crossover Point | ✅ Outperforms when lid size is above 40 mm | ✅ Performs better below 40 mm |

| Temperature Uniformity | ΔT = 1.61°C ➜ 6.77× better uniformity | ΔT = 12.51°C |

| Thermal Resistance | Up to 50% lower | Higher |

| Power Limit | ⚠️ Typical limit at 500 W (risk of dry-out) | ✅ Stable even above 500 W |

| Thickness | ~0.2–0.25 mm | >1 mm |

| Weight | 🚀 Much lighter (hollow structure) | ❌ Heavier (solid metal) |

| Thermal Conductivity (Cu) | 398 W/m·K | 398 W/m·K |

In our experience, the vapor chamber’s two-dimensional heat spreading delivers a dramatic improvement in surface uniformity compared to the solid copper block. Yet, the crossover at around 40 mm indicates that design size and power level still define which material performs better.

Mechanisms and Applications

Vapor chambers rely on a phase-change mechanism that uses internal liquid evaporation and condensation to move heat in two dimensions. This creates nearly uniform surface temperatures and minimizes hotspots, especially when the surface area exceeds 40 mm.

- 🚀 Ultra-thin construction (~0.2 mm) provides lightweight thermal performance for laptops, GPUs, and compact electronics.

- ✅ Excellent lateral heat spreading leads to temperature consistency across the entire surface.

- ⚠️ Limited to around 500 W before potential dry-out occurs.

By contrast, copper blocks operate on pure conduction. They perform best under high power density and compact contact zones below 40 mm, where uniformity is less critical than raw conduction efficiency.

- ✅ Strong direct conduction path supports dense power loads.

- ❌ Less capable of spreading heat laterally across larger areas.

- ⚠️ Added weight and bulk make them less suitable for mobile designs.

In applications where weight and uniformity are key, such as cooling a modern laptop GPU, vapor chambers excel. For high-power inverter modules or compact industrial parts, copper blocks can still provide the right balance of reliability and performance.

Common Misconceptions and Expert Recommendations

Many assume a vapor chamber always offers better cooling, but our studies show that copper blocks remain more dependable for small dies or extremely high power density modules. Their simplicity and higher dry-out resistance can be important for power electronics and industrial designs.

Vapor chambers, on the other hand, stand out in thin, wide, or weight-sensitive systems like notebooks and gaming GPUs, where consistent surface temperature is vital. They use efficient heat spreading to minimize temperature gradients across large areas.

- 💡 Choose vapor chambers when surface area is >40 mm and uniform temperature is a design priority.

- ✅ Opt for copper blocks when handling >500 W or facing space limits requiring solid conduction.

- ⚙️ Always assess power density, lid size, and weight constraints before selecting a cooling device.

From Walmate Thermal’s two decades of research, the key takeaway is matching the device’s power and form factor with the right heat spreader type. This engineering-driven balance ensures steady performance and longevity for both vapor chamber–based and copper-based designs.

Is It Worth the Cost? Performance Analysis

Vapor chambers provide excellent value in compact devices needing silent, maintenance-free cooling with uniform heat distribution, suitable for moderate heat loads. Liquid cooling systems outperform vapor chambers in handling higher heat loads and offer better cost efficiency for large-scale high-power applications.

Both vapor chambers and liquid cooling systems play key roles in modern thermal management. The choice often depends on the balance between thermal performance, space limitations, and long-term maintenance needs. Below we analyze their performance and practical trade-offs, drawing from Walmate Thermal’s engineering experience in system-level cooling design.

Performance Comparison

| Metric | Vapor Chamber | Liquid Cooling System |

|---|---|---|

| Heat Dissipation Efficiency | ✅ High and uniform heat spreading, ideal for moderate heat loads | 🚀 Very high efficiency suitable for high-power electronics and dense circuits |

| Thermal Response Time | ✅ Quick phase-change response for fast heat equalization | ⚠️ Slightly slower, depends on fluid circulation speed |

| Maximum Heat Load Capacity | ❌ Best for moderate TDP applications like laptops and GPUs | ✅ Supports high heat loads for overclocked CPUs, GPUs, and servers |

From Walmate Thermal’s field data, vapor chambers respond faster and spread heat evenly across the surface, especially beneficial in compact spaces. Liquid cooling systems outperform in sustained heavy loads and large thermal footprints.

Practical Advantages and Constraints

- 💡 Space Requirements: Vapor chambers are thin and compact, easily integrated into laptops, GPUs, and smartphones. Liquid cooling systems take more space, making them suited for servers and industrial control modules.

- ✅ Noise and Maintenance: Vapor chambers run silently and need no maintenance thanks to their sealed design. Liquid systems can generate pump noise and need regular checks to prevent leaks.

- ⚠️ Cost Considerations: Vapor chambers have higher unit manufacturing costs at scale, while liquid cooling has higher upfront cost but better scalability in large, high-power projects.

Walmate engineers often recommend vapor chambers for portable and consumer devices where silent performance and reliability outweigh fast fluid-based dissipation. For rack-mounted or industrial systems, liquid cooling proves more cost-effective over long operation cycles.

Critical Perspective and Application Guidance

- ✅ Vapor chambers deliver optimal results where space is tight and heat loads are moderate, such as consumer electronics and thin form-factor GPUs.

- ⚙️ Liquid cooling is essential for scenarios with high or sustained heat output like data centers, AI training servers, or high-end overclocked PCs.

- 💡 Hybrid setups, combining vapor chamber base plates with liquid loops, are increasingly deployed to balance rapid heat spreading and efficient heat rejection.

- ⚠️ Decision factors should include total cost of ownership, maintenance requirements, and potential downtime from servicing or cooling failure.

Based on Walmate Thermal’s almost 20 years of experience in customized cooling system design, the right selection depends on matching the thermal profile with spatial and operational constraints rather than choosing by headline capability alone. Both vapor chambers and liquid cooling remain integral to modern thermal engineering strategies.

The Future of Cooling: 3D Vapor Chambers?

3D vapor chambers are rapidly emerging as the next evolution in cooling technology, with the global 3D vapor chamber market projected to quadruple in value from $1.2 billion in 2024 to $4.7 billion by 2033, driven by demand for ultra-thin, high-efficiency cooling in advanced electronics and AI-integrated devices.

Compact electronic devices and AI-integrated systems are pushing thermal performance to new limits. As a result, 3D vapor chamber cooling has become one of the most discussed technologies in advanced system design. In our experience at Walmate Thermal, this shift represents a transformative step in how engineers manage heat in high-density hardware.

Market Growth and Adoption Trends

The 3D vapor chamber market has experienced substantial momentum over the past few years, supported by rising needs in smartphones, laptops, and GPU cooling solutions.

| 💡 Indicator | 🚀 Data Insight |

|---|---|

| Market Size | $1.2 billion (2024) → $4.7 billion (2033) |

| CAGR | 26.37% (2025–2034 overall) | 15.2% (3D vapor chamber through 2031) |

| Smartphone Adoption | Up to 85% penetration in 2024 (from 53% in 2020) |

| Ultra-Thin Segment Share | 38% of the vapor chamber market by 2025 |

| Regional Dominance | Asia-Pacific holds >45% market share (2025) |

Technological Advantages and Applications

3D vapor chambers are redefining what is possible in compact electronics. They enable efficient heat dissipation for high-power components like GPUs, laptops, and AI accelerators while maintaining thin device profiles.

- ✅ Multi-layer 3D design provides uniform cooling over complex chip surfaces, outperforming flat vapor chambers and heat pipes.

- ✅ Effective thermal dissipation supports devices requiring over 100W in confined spaces.

- ✅ Ultra-thin vapor chambers as slim as 0.4 mm are now common in flagship smartphones.

- ✅ Integrated thermal management solutions can cut system energy use by up to 20%.

At Walmate Thermal, such innovations align directly with our advanced R&D efforts in AI cooling, battery systems, and power electronics. Our engineering teams leverage CFD simulations and material innovations to design customized, high-precision vapor chamber systems.

Challenges and Industry Response

Despite strong outlook, manufacturing complexity and material costs remain major challenges for 3D vapor chamber scalability.

- ⚠️ Dual-layer chamber production involves up to 12 precise machining steps, extending lead times by about 45%.

- ⚠️ Copper price hikes—from $8,300/ton to $9,700/ton (2020–2024)—add around 28% to production cost.

- 🚀 R&D funding in flexible and thin vapor chamber solutions grew by 31%, signaling strong innovation focus.

- ✅ Economies of scale and newer materials aim to bring costs down and improve availability.

- 💡 Buyers should assess suppliers’ precision, consistency, and customization capacity, as the top 5 producers hold over 40% of market share.

Walmate Thermal’s in-house manufacturing capabilities, including three production bases and over 1000 employees, enable precise control throughout the design and fabrication cycle — a critical advantage in this evolving space.

Common Misconceptions and Market Insights

The market often underestimates the performance leap provided by 3D vapor chambers. In reality, they deliver much higher heat spreading efficiency vital for next-generation electronics.

- ✅ They outperform heat pipes in both thermal spreading and integration flexibility.

- ✅ Critical for small-form devices with high power density, especially in premium systems and AI hardware.

- ✅ Although cost remains higher, energy efficiency and longer component life greatly offset investment.

- 💡 Strong supply partnerships focused on tailored engineering deliver measurable performance advantages.

- 🚀 Expanding use across electronics, EVs, and IoT products indicates a fast-approaching mainstream adoption phase.

As a long-term specialist in thermal management, Walmate Thermal integrates 3D vapor chamber research into broader system-level cooling solutions — from data center servers to electric vehicle electronics — helping manufacturers meet rising thermal demands without compromise.

The Garage Guru’s Take on Premium Cooling Tech

Premium cooling technology plays a critical role in maintaining optimal performance and reliability in high-demand applications by efficiently managing heat. These advanced cooling solutions incorporate specialized materials and designs to ensure precision temperature control, which protects components and extends product lifespan.

Premium cooling technology refers to advanced thermal management systems that control and dissipate heat efficiently in electronic and industrial equipment. It’s not only essential for keeping systems stable but also for improving energy efficiency and ensuring product durability. In our experience working with heat-intensive devices like GPUs and laptops, the right cooling design makes a measurable difference in performance consistency.

Walmate Thermal develops a wide range of premium cooling solutions designed for these needs. Some of the most common types include:

- 💡 Heat sinks – for natural and forced convection cooling.

- 💡 Liquid cooling plates – ideal for high-power systems such as EV inverters.

- 💡 TEC modules – offering precise temperature control for medical or optical devices.

- 💡 Vapor chambers – for even heat spreading in compact designs like gaming laptops.

Adopting these technologies helps companies achieve lighter, more power-efficient designs. Industries like electric vehicles, AI data centers, and automation increasingly rely on accurate thermal balance to maintain uptime and extend hardware life. For example, vapor chamber cooling is becoming a preferred choice for compact GPU and CPU configurations because it provides high heat transfer efficiency across a flat surface area.

Behind these solutions lie years of R&D and technical refinement. Walmate’s engineering team of over 100 specialists develops custom thermal systems tailored to each client. Their continuous innovation—supported by 20+ years in the industry—ensures every cooling product, from vapor chambers to liquid plates, meets both performance and reliability demands in today’s evolving market.

FAQs: About Vapor Chambers

What is a vapor chamber?

A vapor chamber is a flat, sealed device that transfers heat through phase change. Inside, it contains a small amount of working fluid. When a heat source like a GPU or CPU warms one area, the fluid evaporates and spreads heat evenly across the chamber’s surface.

Once the heat dissipates, the vapor condenses into liquid and returns to the heat source through a wick structure. This continuous cycle keeps components cool while maintaining temperature uniformity across the surface.

Are vapor chambers better than heat pipes?

Vapor chambers and heat pipes use the same principle of phase change, but a vapor chamber spreads heat more uniformly across its surface. This makes it especially useful in compact GPUs and high-end laptops where space and even heat distribution matter.

While heat pipes are more cost-effective and efficient in linear layouts, vapor chambers excel at managing thermal hotspots for power densities above 100 W/cm². In our experience, using both together often delivers the best balance of performance and cost.

Which cooler uses a vapor chamber?

Vapor chambers are common in high-performance GPU coolers, gaming laptops, and server processors. They are also used in industrial equipment and data center cooling systems that handle high heat flux or require compact form factors.

Walmate Thermal integrates vapor chamber technology into custom thermal modules for demanding sectors like AI servers and EV electronics. The goal is to improve heat transfer speed and uniformity in power-dense systems.

How does a vapor chamber work?

A vapor chamber works through continuous phase change. Heat input causes the internal liquid to vaporize, which moves rapidly to cooler regions across the chamber. There, it releases heat, condenses back into a liquid, and travels through the wick to restart the cycle.

This closed-loop process enables efficient, passive heat transfer with minimal temperature difference—often within 2–3°C across the surface, even under high load conditions.

Is a vapor chamber worth the extra cost?

Yes, especially for devices with limited cooling surface or high power output. Vapor chambers offer flatness, low thermal resistance, and even temperature distribution, improving component reliability and sustained performance.

While they cost more than traditional heat pipes, the benefits include quieter operation, longer device lifespan, and higher performance stability—advantages that justify the investment in premium GPUs, laptops, or industrial systems. Walmate Thermal’s engineering team often recommends them for customers prioritizing long-term thermal efficiency and reliability.

Final Thoughts

Vapor chambers are reshaping modern cooling design, delivering the planar heat spreading that high-density GPUs, AI processors, and ultra-thin laptops demand. Compared to traditional heat pipes or copper blocks, they offer lighter, more uniform, and silent thermal management while maintaining temperature stability across wider surfaces. These advantages come with higher production precision and cost, but the performance payoff is clear in sustained efficiency and product longevity.

As systems trend toward higher power and smaller footprints, the shift toward vapor chambers and 3D-integrated designs will define the next phase of cooling innovation. Partnering with an experienced engineering supplier ensures that design teams can match the right technology to performance targets, creating thermal solutions that enhance reliability and maintain competitive advantage in demanding markets.