In the world of product design, few choices are as fundamental as the one between active and passive cooling. This single decision impacts everything: your product’s performance, its final cost, long-term reliability, physical size, and even the user’s experience. Get it right, and your device runs flawlessly. Get it wrong, and you’re left with an underperforming, unreliable product that fails to meet customer expectations. It’s a foundational engineering trade-off that every design team must master.

The core difference between active and passive cooling lies in energy input. Passive cooling dissipates heat using natural convection, conduction, and radiation without any external power (e.g., a heat sink). Active cooling uses external energy and moving parts, like fans or pumps, to accelerate heat removal, offering much higher performance for a given size.

But how do you know which approach is right for your specific project? This guide provides a comprehensive engineering framework to help you choose. We will dive deep into the science behind each method, offer a head-to-head comparison, provide a clear decision-making matrix, and explore real-world applications. By the end, you will have the knowledge to select the optimal thermal solution and ensure your project’s success from the very first design sketch.

? The Science of Silent Thermal Management

? The Science of Silent Thermal Management

Passive cooling is a thermal management method that relies entirely on the natural laws of physics to dissipate heat. It uses zero external power and has no moving parts, making it an inherently silent and reliable solution. By leveraging the principles of conduction, convection, and radiation, a passive cooler, like a heat sink, can effectively move thermal energy from a hot component into the surrounding environment without any assistance.

How Does Passive Cooling Work? The Three Pillars of Natural Heat Transfer

Passive cooling works by orchestrating a seamless transfer of heat through three natural mechanisms:

- Conduction: This is the first step. Heat moves from the hot electronic component directly into the base of the passive cooler (e.g., a heat sink) through direct physical contact. Materials with high thermal conductivity, like aluminum and copper, are used to make this process as efficient as possible.

- Natural Convection: Once the heat has spread throughout the cooler, it warms the surrounding air. This heated air becomes less dense and naturally rises. As it rises, it pulls in cooler, denser air from below to take its place. This creates a slow but continuous, silent airflow that carries heat away from the cooler’s fins.

- Radiation: All objects with a temperature above absolute zero emit thermal energy as electromagnetic waves. A passive cooler with a large, dark, and matte surface will radiate heat into its surroundings. In a system with low airflow, this can account for a significant portion of the total heat dissipated.

What Are Common Examples of Passive Coolers?

The world of passive cooling is dominated by a few key components, often used in combination:

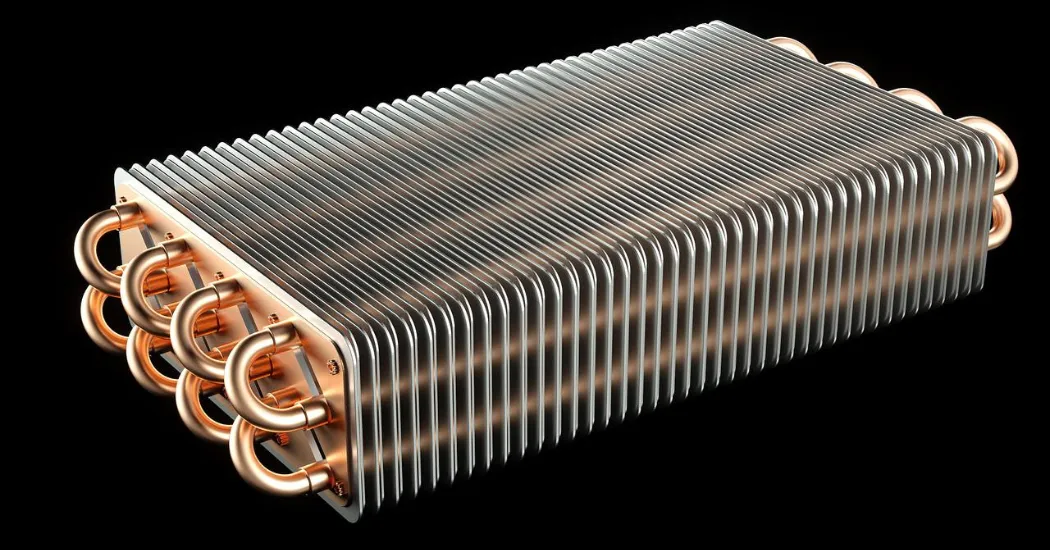

- Heat Sinks: These are the most common passive coolers. They are blocks of metal, typically aluminum, with many fins designed to maximize surface area for natural convection and radiation. They are made using processes like extrusion or skiving to create complex fin geometries.

- Heat Spreaders: A heat spreader is a flat plate of highly conductive material (like copper or an aluminum vapor chamber) used to take heat from a small, concentrated hot spot and spread it over a larger area. This larger area can then be cooled more effectively by a heat sink.

- Heat Pipes: These are clever devices that use a phase-change cycle to move heat with incredible efficiency. A liquid inside a sealed copper tube vaporizes at the hot end, travels as a gas to the cool end, condenses back into a liquid, and returns. A single heat pipe can move a large amount of heat with very little temperature difference, making it a powerful tool in passive design.

What Are the Pros and Cons of Passive Cooling?

Passive cooling is an elegant solution, but it’s a game of trade-offs. Its greatest strengths are also linked to its biggest limitations.

The primary advantage of passive cooling is its absolute reliability. With no moving parts to wear out, no fans to fail, and no power required, it is a true “set it and forget it” solution. However, this reliability comes at the cost of lower performance and larger physical size compared to active solutions.

Key Advantages:

- Unmatched Reliability (High MTBF): No moving parts means there is nothing to break or wear out over time.

- Silent Operation: The absence of fans or pumps makes it completely silent.

- Zero Power Consumption: It does not add to the system’s power budget.

- Lower Cost & Simplicity: Fewer components mean lower manufacturing and assembly costs.

Key Disadvantages:

- Lower Performance Ceiling: It is not suitable for high-TDP components or very high heat fluxes.

- Larger Size and Weight: To dissipate the same amount of heat, a passive cooler must be significantly larger than an active one.

- Dependent on Environment: Its performance is highly sensitive to ambient temperature and chassis orientation/ventilation.

What is Active Cooling? Adding Power to Overcome Thermal Limits

Active cooling is a thermal management strategy that introduces external energy—typically in the form of a fan or a pump—to dramatically accelerate heat removal. Unlike passive cooling, which waits for nature to take its course, active cooling takes control. By forcefully moving a cooling medium (like air or liquid) across a heat exchanger, it overcomes the limitations of natural convection, allowing for significantly higher performance in a much smaller space.

How Does Active Cooling Work? The Principle of Forced Convection

The core principle of active cooling is forced convection. In any cooling scenario, a thin, slow-moving layer of fluid known as the “boundary layer” forms on the surface of a heat sink. This layer acts like an insulator, slowing down heat transfer. Natural convection is not very effective at disrupting this layer.

An active system solves this problem directly. By using a fan to blow air or a pump to push liquid, it introduces a high-velocity flow that continuously breaks up this insulating boundary layer. This allows cooler fluid to constantly make contact with the hot surface, resulting in a dramatically higher rate of heat transfer. This is why adding even a small fan to a heat sink can double or triple its cooling capacity.

What Are Common Examples of Active Coolers?

Active cooling solutions are everywhere in modern electronics, especially where high performance is required:

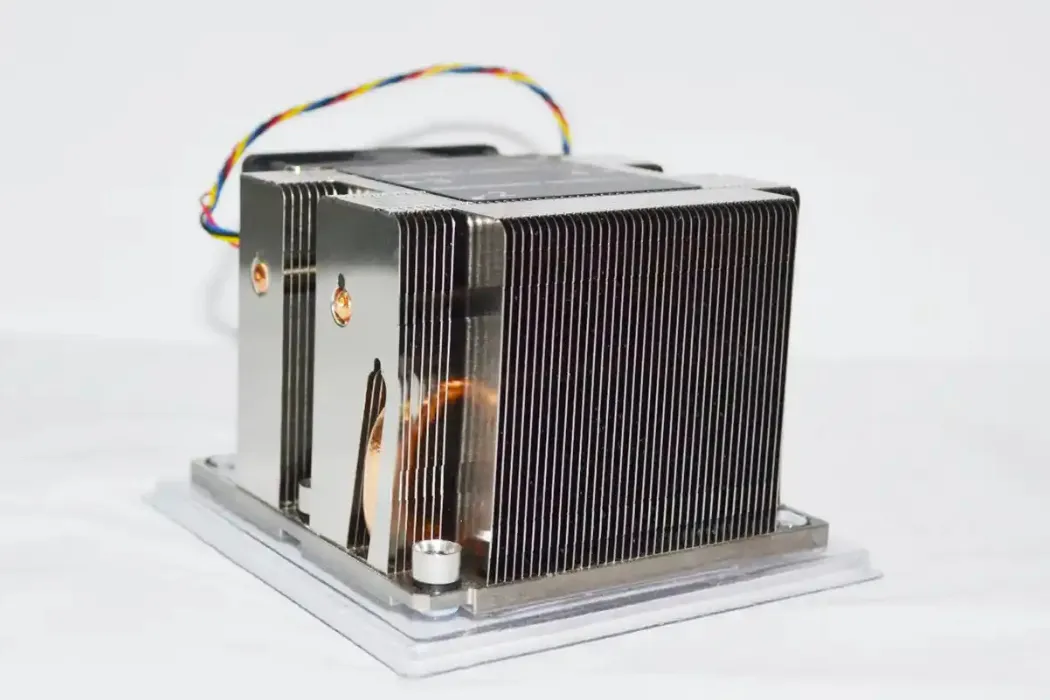

- Fan-on-Heatsink Assemblies: This is the most common form of active cooling. It consists of a passive heat sink paired with a dedicated fan. The fan ensures a constant supply of cool air flows over the fins. This is the standard cooling solution for virtually all desktop CPUs, GPUs, and power supplies.

- Liquid Cooling Loops: For the most demanding thermal challenges, liquid cooling is the ultimate active solution. These systems use a pump to circulate a liquid coolant through a liquid cold plate (which absorbs heat from the component) to a radiator. A fan on the radiator then dissipates the heat from the liquid into the air. This method is used in high-end gaming PCs, data centers, and EV battery packs.

What Are the Pros and Cons of Active Cooling?

Active cooling delivers the high performance that modern electronics demand, but this power comes with its own set of trade-offs related to complexity, cost, and reliability.

The defining advantage of active cooling is its high performance-to-size ratio. It can dissipate a massive amount of heat from a very small volume, enabling the creation of powerful, compact devices. However, this performance is dependent on moving parts, which introduces potential points of failure, noise, and power consumption.

Key Advantages:

- High Performance Ceiling: It can handle very high TDPs and concentrated heat fluxes with ease.

- Compact and Lightweight: For a given thermal load, an active cooler is significantly smaller and lighter than a passive equivalent.

- Less Dependent on Environment: It is less affected by system orientation and can better manage high ambient temperatures.

Key Disadvantages:

- Lower Reliability (Lower MTBF): Moving parts like fans and pumps have a finite lifespan and can fail.

- Noise Generation: Fans and pumps produce acoustic noise, which can be a negative factor in many applications.

- Power Consumption: It requires electrical power to operate, adding to the system’s overall power budget.

- Higher Cost and Complexity: The inclusion of fans, pumps, and control circuitry increases the overall cost and design complexity.

Active vs. Passive Cooling: A Head-to-Head Comparison

When you place active and passive cooling side-by-side, the fundamental engineering trade-off becomes crystal clear. It’s a choice between the high performance and compact size of an active system and the absolute reliability and simplicity of a passive one. Neither is universally “better”—the optimal choice depends entirely on the specific priorities and constraints of your project.

Performance: The Power of Forced Airflow

There is no contest here. Active cooling is vastly superior in thermal performance. By using forced convection, an active cooler can remove heat many times faster than a passive cooler of the same size. This allows it to handle much higher heat loads (TDPs) and keep components at lower temperatures, which in turn unlocks higher processing speeds and prevents performance throttling.

Reliability and Lifespan: The Moving Parts Problem

This is where passive cooling holds the decisive advantage. A passive heat sink has a Mean Time Between Failures (MTBF) that is practically infinite; it’s a solid block of metal. An active cooler, however, contains moving parts—fan bearings or pump impellers—that have a finite lifespan. They can wear out, get clogged with dust, or fail electronically. For mission-critical applications where failure is not an option, the **unmatched reliability of a passive system** is often the top consideration.

Cost: The Trade-off Between Design and Components

The cost comparison is nuanced. A simple passive heat sink is generally cheaper than a fan-and-heatsink assembly. However, a highly complex, custom-designed passive solution for a high-power application can be more expensive than a standard active cooler. The true cost analysis involves:

- CAPEX (Capital Expenditure): Active systems have a higher component cost (fans, pumps, controllers). Large passive systems may have higher initial engineering and material costs.

- OPEX (Operational Expenditure): Active systems consume power, adding to the lifetime operational cost. They may also require maintenance (e.g., fan replacement), while passive systems have zero operational cost.

| Metric | Passive Cooling | Active Cooling |

|---|---|---|

| Performance Ceiling | Low to Moderate | Very High |

| Reliability (MTBF) | Extremely High (Virtually Infinite) | Moderate (Limited by Fan/Pump Life) |

| Power Consumption | Zero | Low to High |

| Acoustic Noise | Silent | Quiet to Loud |

| Cost (CAPEX vs. OPEX) | Low CAPEX, Zero OPEX | Higher CAPEX, Non-Zero OPEX |

| Design Complexity | Requires careful airflow/chassis design | Requires power and control integration |

How Do You Choose? A 5-Point Decision-Making Framework

Making the right choice between active and passive cooling isn’t a guess—it’s a systematic process of evaluating your project’s specific needs. By asking the right questions and weighing the critical trade-offs, you can confidently select a strategy that aligns with your performance targets, reliability requirements, and budget. This 5-point framework serves as an engineer’s checklist for making an informed decision.

Factor 1: What is Your Heat Load (TDP)?

This is the most important starting point. The Thermal Design Power (TDP) of your component sets the stage. As a general rule, low-to-moderate TDPs (typically under 30-40W) are excellent candidates for passive cooling, provided there is adequate space. Once the heat load increases, especially for components with high heat flux, the scale tips decisively toward active cooling.

Factor 2: What Are Your Space and Weight Constraints?

The physical volume available for the cooling solution is a critical constraint. Passive cooling requires a large surface area to work effectively, meaning it needs a **large, heavy heat sink**. If your product is a compact, portable, or weight-sensitive device, a much smaller and lighter active cooling solution is almost always the only viable option to achieve the necessary performance.

Factor 3: What is the Operating Environment?

Where will your product live? A device operating in a climate-controlled office has very different needs from one in a sealed industrial enclosure on a hot factory floor. Passive cooling relies on cool ambient air and good ventilation. In an environment that is **hot, dusty, or sealed (IP rated)**, a passive solution will struggle, making a robust active system a necessity.

Factor 4: What Are the Reliability and Maintenance Requirements?

This question is about risk. If thermal failure would be catastrophic or if the device will be installed in a remote location where maintenance is impossible, reliability is the number one priority. In these cases, the **”no moving parts” advantage of passive cooling** makes it the clear winner. If a fan failure can be tolerated or easily serviced, then active cooling is a perfectly acceptable choice.

Factor 5: What is Your Cost and Power Budget?

Finally, consider the budget. If the system has **no available power for a fan** or if **acoustic noise must be zero**, passive cooling is your only option. From a cost perspective, while a simple passive heat sink is cheap, a large, custom passive solution can be expensive. You must balance the upfront component cost (CAPEX) of an active system against its long-term power and potential maintenance costs (OPEX).

| Design Factor | Choose Passive If… | Choose Active If… |

|---|---|---|

| Heat Load (TDP) | TDP is low to moderate (< 40W) | TDP is high (> 40W) or heat flux is high |

| Available Space | Space is plentiful | Space is limited and compact design is key |

| Ambient Temperature | Environment is cool and well-ventilated | Environment is hot, sealed, or poorly ventilated |

| Reliability Needs | System is mission-critical; failure is not an option | Maintenance is possible; fan failure is not catastrophic |

| Noise Constraints | The system must be completely silent | Some level of acoustic noise is acceptable |

| Power Budget | There is no available power for fans/pumps | There is sufficient power for fans/pumps |

What Are Real-World Examples and Use Cases?

Theory and decision frameworks are essential, but seeing these cooling strategies in action provides the clearest understanding. The choice between active and passive cooling defines the products we use every day. From the silent, reliable operation of your Wi-Fi router to the high-performance roar of a gaming PC, these real-world examples showcase the engineering trade-offs at play in different applications.

Passive Cooling in Action: LED Lighting & Consumer Electronics

Passive cooling is the unsung hero of many devices where reliability and silence are paramount. High-power LED lighting is a perfect example. An outdoor LED street light or stadium light needs to operate flawlessly for years with zero maintenance. A fan would be a critical point of failure, susceptible to dust and moisture. Instead, these lights use a large, robust, custom-designed passive heat sink—often the fixture’s own metal housing—to dissipate heat silently and reliably for decades.

You also find passive cooling in many consumer electronics like Wi-Fi routers, streaming devices, and cable boxes. For these “always-on” devices, a silent, reliable, and low-cost thermal solution is essential. A simple extruded aluminum heat sink is often all that’s needed to keep the low-power processors cool without adding noise or a mechanical failure point to the product.

Active Cooling in Action: Desktop PCs & Data Center Servers

When performance is the primary goal, active cooling is non-negotiable. Your desktop gaming PC is the classic example. The high-TDP CPU and GPU generate an immense amount of heat in a small area. To prevent throttling and unlock the full performance, a powerful fan-on-heatsink assembly or a liquid cooling loop is required. The noise and power consumption are acceptable trade-offs for achieving maximum frame rates and processing speeds.

This principle scales up massively in data centers. Racks filled with dozens of high-power servers generate kilowatts of heat in a confined space. This requires a powerful, system-level active cooling strategy, using thousands of high-speed fans and complex air conditioning systems to manage the immense thermal load and keep the servers running 24/7.

The Hybrid Approach: Industrial Power Systems & Telecom Enclosures

Sometimes, the smartest solution is a hybrid of both. Consider a sealed telecom enclosure or a NEMA-rated industrial controller. These systems need to be protected from harsh, dusty environments, but also need to dissipate significant heat. A common solution is to use a large internal passive heat sink to absorb the heat, which then transfers it to an external heat sink via heat pipes. A fan on the external heat sink can then dissipate the heat to the outside air.

A hybrid approach can also be used for smart control. An industrial power system might rely on passive cooling for normal operation, but have an emergency fan that only activates when the system reaches a critical temperature threshold. This provides the day-to-day reliability of a passive system with the safety net of an active one.

How Do Manufacturing Processes Influence Your Choice?

Your choice between active and passive cooling is not just a thermal decision; it’s a manufacturing and supply chain decision. The strategy you select directly influences the materials, technologies, and type of expert partner you will need to bring your product to life. Understanding this link is key to creating a solution that is not only effective but also manufacturable at scale.

Designing for Passive: The Art of Maximizing Surface Area

In a passive system, the physical design of the heat sink is the performance. The entire goal is to maximize surface area in a given volume to enhance natural convection and radiation. This requires expertise in specialized metal fabrication techniques:

- Extrusion: A cost-effective process for creating aluminum heat sinks with consistent fin profiles, ideal for many standard applications.

- Skiving: A more advanced technique that carves ultra-thin, high-density fins from a solid block of copper or aluminum. This method creates significantly more surface area, enabling high-performance passive cooling in a smaller space.

Success in passive cooling depends on a partner with deep knowledge of thermal dynamics and advanced metalworking capabilities.

Engineering for Active: Integrating Fans and Liquid Loops

An active solution is more than just a heat sink; it’s an electromechanical assembly. The challenge shifts from pure metal design to systems integration. An active cooling solution requires sourcing and integrating multiple components: the heat sink or cold plate, fans or pumps, shrouds for directing airflow, and the necessary power and control wiring.

This demands a different skill set from your manufacturing partner. They need expertise in sourcing reliable fans and pumps, managing a more complex bill of materials (BOM), and implementing quality control for the entire assembly, not just the metal components.

Why Your Choice Affects Your Supply Chain and Manufacturing Partner

Ultimately, your cooling strategy dictates the type of supplier you need. Do you need a metal fabrication expert or a systems integrator? Often, a project can start with one strategy and evolve to another as requirements change. This is why partnering with a versatile manufacturer is a significant strategic advantage.

A partner like Walmate Thermal, with expertise across the full spectrum—from advanced passive heat sinks to fully assembled active cooling modules—can provide unbiased guidance from the very beginning. We can help you make the right choice based on thermal simulation and then execute on that choice, whether it requires complex skived fins or a fully integrated fan assembly. This simplifies your supply chain and de-risks your entire project.

Frequently Asked Questions (FAQs)

1. Is a heat sink with a heat pipe considered active or passive cooling?

It is 100% passive. A heat pipe is a powerful component that moves heat very efficiently, but it does so through a natural phase-change process that requires no external power. It is a key technology for enhancing high-performance passive solutions.

2. Can you turn a passive cooling solution into an active one?

Yes, easily. The most common type of active cooler is simply a passive heat sink with a fan attached. By adding a fan, you convert the system from relying on natural convection to using forced convection, dramatically increasing its performance.

3. Is liquid cooling always an active system?

In the context of electronics cooling, yes, it is considered an active system. All standard liquid cooling loops rely on a pump (an active component that consumes power) to circulate the coolant. While some large-scale, purely passive industrial thermosiphons exist, they are not used for typical electronic applications.

4. Which cooling method is more expensive?

It depends. For a given low-power application, a simple passive heat sink is cheaper. However, for a high-power application, a massive, complex passive solution can be more expensive than a more compact and efficient active solution. Active cooling often has a higher upfront component cost, but can be cheaper overall for high-performance needs.

5. What is “hybrid cooling”?

Hybrid cooling is a smart strategy that combines both active and passive elements. A common example is a system that operates silently in a passive mode during normal, low-load conditions, but activates a fan (active mode) only when the temperature hits a certain threshold during a heavy workload.

6. How do I know if my passive cooling design is sufficient?

The only way to know for sure without costly physical trial-and-error is through professional thermal simulation (CFD). This analysis creates a digital model of your device to accurately predict its temperatures. This is a core part of our design service at Walmate Thermal to guarantee your solution will work as intended.

7. What is more important: the heat sink’s size or the fan’s speed?

They are both critical parts of a balanced equation. A large heat sink provides the surface area, and a fast fan provides the airflow. A very large heat sink might work well with a slow, quiet fan, while a smaller heat sink would require a faster, louder fan to achieve the same performance. The optimal design is one where both are properly matched.

8. Do you manufacture both active and passive cooling solutions?

Yes. This is a key advantage of working with Walmate Thermal. Our expertise covers the full spectrum, from designing and manufacturing custom passive heat sinks using advanced techniques like skiving, to engineering and building complete active cooling assemblies. This allows us to provide an unbiased, expert recommendation for the best strategy for your specific project.

Conclusion: Making the Right Thermal Trade-Off

The choice between active and passive cooling is a foundational engineering decision, a critical trade-off between performance, reliability, cost, and complexity. As we’ve explored, there is no single “best” answer that fits all applications. The silent, unwavering reliability of a passive heat sink is perfect for one project, while the compact, high-power performance of an active system is essential for another.

The optimal solution, therefore, is never an off-the-shelf guess. It is a solution that is perfectly tailored to the unique thermal, mechanical, and commercial demands of your project. This requires expert analysis to choose the right strategy and a custom-designed solution to execute it flawlessly, whether that’s a high-performance passive heat sink or a fully integrated active cooling assembly.

Don’t guess on your most critical design decisions.

At Walmate Thermal, our expertise covers the full spectrum of thermal management. We help you choose the right strategy using advanced thermal simulation and then design and manufacture the perfect custom solution for your needs—from complex passive heat sinks to complete active cooling systems.Contact our engineers today for a consultation, and let’s build a solution that is not just cool, but smart.