Modern technology is running hotter than ever. Industries pushing the boundaries of innovation—from electric vehicles and AI data centers to energy storage systems—are all hitting the same fundamental obstacle: a thermal wall. The relentless increase in power density means traditional air-cooling methods are no longer just inefficient; they are a direct bottleneck to performance. Fans and heat sinks, once the workhorses of thermal management, simply can’t keep up. This challenge is forcing engineers to rethink cooling from the ground up, seeking a solution that doesn’t just manage heat, but enables the next generation of power and performance. That solution is the liquid cold plate.

A liquid cold plate is a high-performance heat exchanger that transfers heat from a hot device directly to a circulating fluid. It uses a metal plate with internal channels to provide precise, targeted cooling for high-power electronics. This method is far more efficient than air cooling, enabling greater power density, performance, and reliability. It is the key to unlocking the full potential of today’s most advanced systems.

But choosing the right cold plate is a complex engineering decision. With a dozen different manufacturing processes and materials to choose from, how do you know which one is right for your project? This is more than a simple guide. We will dive deep into the core manufacturing technologies, compare every type of cold plate head-to-head, and walk you through a complete engineering design process. By the end, you will be equipped with the knowledge to create the perfect thermal solution for your most demanding challenges. Let’s begin.

Why Do We Urgently Need Liquid Cold Plates? The End of the Air-Cooling Era

We need liquid cold plates because the power density of modern electronics has surpassed the physical limits of air cooling. As components like CPUs, GPUs, and EV batteries become more powerful and compact, they generate intense, concentrated heat that air simply cannot remove effectively. This creates a performance bottleneck that only liquid cooling can solve, making it an essential technology for innovation. It’s no longer a choice, but a necessity for progress.

The Unstoppable Rise of Power Density

The trend across all high-tech industries is clear: more power in less space. An AI data center GPU that drew 300 watts a few years ago now pushes over 1,000 watts. A single electric vehicle battery module, the size of a briefcase, can generate thousands of watts of heat during a fast charge. This concentration of heat is known as “heat flux,” and it has grown exponentially.

Think of it like trying to cool a red-hot stovetop burner with a small desk fan. At a certain point, no matter how fast the fan spins, it just can’t move enough air to make a difference. The burner stays hot. Modern electronics are now filled with these “stovetop burners,” and our old fan-based solutions are failing.

What Are the Physical Limits of Air Cooling?

Air is a poor thermal conductor. It has a low density and low specific heat capacity, meaning it can’t absorb and carry away heat very well. For decades, engineers compensated for this by using larger heat sinks with more fins and more powerful fans. But we have now reached a point of diminishing returns. To cool today’s high-TDP components with air, a heat sink would need to be impractically large, heavy, and loud. The physical space and power required to run the massive fans needed would negate any benefits. Air cooling has hit its physical wall.

How Liquid Cooling Unlocks Performance and ROI

Liquid cooling is not just about preventing meltdowns; it’s about unlocking potential. When components run cooler, they run faster and more reliably. A liquid cold plate is a strategic investment that pays dividends by directly boosting performance and long-term value. Key benefits include:

- Eliminating Performance Throttling: Liquid cold plates ensure components operate at their optimal temperature. This stops a chip from slowing itself down to avoid overheating, meaning you get the full performance you paid for, 100% of the time.

- Enabling Compact & Powerful Designs: Because liquid cooling is so much more effective, engineers can pack powerful components closer together. This leads to smaller, lighter, and more energy-efficient products without sacrificing power.

- Delivering a Strong Return on Investment (ROI): The initial investment in a liquid cooling system is often offset by significant long-term savings. The improved performance, increased hardware reliability, and superior energy efficiency deliver a clear and significant return on investment (ROI) over the product’s lifespan.

How Do Liquid Cold Plates Work? The Core Principles of Heat Transfer

A liquid cold plate works by using two fundamental heat transfer principles in sequence. First, conduction pulls heat from a hot component into the cold plate’s metal base. Second, convection transfers that heat from the base into a fluid flowing through internal channels. This heated fluid is then pumped away to a heat exchanger, like a radiator, where it is cooled before returning to the cold plate to repeat the cycle, creating a continuous and highly efficient cooling loop.

Conduction: The First Step from Chip to Plate

The entire process begins with direct contact. The base of the liquid cold plate, a smooth, flat metal surface, is mounted directly onto the heat-generating component (like a GPU or an IGBT module). To ensure maximum heat transfer, a thin layer of Thermal Interface Material (TIM) is applied between the two surfaces. This material fills in microscopic air gaps, creating a seamless thermal bridge.

Through the process of conduction, thermal energy naturally flows from the hotter component into the cooler metal of the cold plate’s baseplate. The better the conductivity of the metal (e.g., copper or aluminum), the faster this heat transfer occurs, effectively pulling heat away from the sensitive electronics.

Convection: Transferring Heat to the Fluid

Once the heat has saturated the base of the cold plate, the second critical step begins: convection. Inside the cold plate is a network of engineered channels or fins. A cool liquid, such as a water-glycol mixture, is continuously pumped through these channels. As the liquid flows past the hot internal surfaces, it absorbs the thermal energy, quickly raising its own temperature and cooling the metal in the process.

The design of these internal channels is critical. More surface area inside the cold plate means more contact with the fluid, leading to faster and more efficient heat transfer. This is why high-performance cold plates often feature complex internal fin structures.

The System View: From Cold Plate to Heat Exchanger

A cold plate does not work in isolation. It is the heart of a larger liquid cooling loop. After the fluid exits the cold plate, now carrying the waste heat, it flows through tubing to a **heat exchanger** (like a radiator). Here, the heat is transferred from the liquid to the ambient air. The now-cooled liquid is then pumped back to the cold plate to begin the process all over again.

It’s helpful to think of the cold plate’s specific job: its role is not to eliminate heat, but to absorb it and move it somewhere else very efficiently. The rest of the cooling loop is then responsible for getting rid of that heat for good.

What are the Advantages and Disadvantages of Liquid Cold Plates?

Liquid cold plates offer overwhelmingly superior thermal performance and enable far greater power density compared to air cooling. Their main advantages include exceptional heat removal, improved energy efficiency, and quieter operation. However, potential disadvantages include higher initial cost (CAPEX), increased system complexity, and the perceived risk of leaks. Fortunately, with proper engineering and a reliable manufacturing partner, these challenges can be effectively mitigated.

The Overwhelming Advantages

Adopting liquid cold plate technology brings a host of powerful benefits that are essential for modern high-performance systems. The advantages go far beyond simply lowering temperatures.

- Superior Thermal Performance: Water has over 3,000 times the heat capacity of air by volume. This allows liquid cold plates to remove large amounts of heat from very small, concentrated areas, a task impossible for even the best air coolers.

- Increased Power Density & Miniaturization: Because they are so efficient, cold plates allow engineers to design more powerful, compact products. You can pack more processing power or battery capacity into the same space without worrying about overheating.

- Enhanced Energy Efficiency: Pumping liquid requires significantly less energy than spinning large, high-speed fans to move the equivalent amount of thermal energy. This leads to a lower Power Usage Effectiveness (PUE) in data centers and reduced energy consumption in other systems.

- Quiet Operation: Liquid cooling systems eliminate the need for loud, high-RPM fans, resulting in a dramatic reduction in acoustic noise. This is a critical factor in medical equipment and high-performance workstations.

Potential Challenges and How to Mitigate Them

While the benefits are clear, engineers must also consider the potential challenges. A successful implementation depends on addressing these points during the design phase.

The primary concern is often the risk of leaks. The idea of putting liquid next to expensive electronics can be daunting. However, this risk is mitigated through robust design and manufacturing. Working with an experienced partner like Walmate Thermal ensures this. We use advanced joining techniques like **vacuum brazing and Friction-Stir Welding (FSW)**, followed by rigorous **100% leak and pressure testing** on every single unit before it ships, virtually eliminating this risk.

Another consideration is **system complexity and initial cost**. A liquid cooling loop has more components than an air cooler. While this leads to a higher initial capital expenditure (CAPEX), it is often offset by a lower operational expenditure (OPEX) over the system’s lifetime due to significant energy savings and improved hardware reliability.

| Aspect | Advantages (Pros) | Disadvantages (Cons) & Mitigation Strategy |

|---|---|---|

| Thermal Performance | Exceptional heat removal capacity; very low thermal resistance. | Performance is dependent on the entire loop (pump, radiator). Mitigation: Proper system-level design and simulation. |

| Power Density | Enables highly compact and powerful product designs. | Requires careful layout planning. Mitigation: Co-design the cold plate with the product layout from the start. |

| Energy Efficiency | Significantly lower energy use compared to air cooling for the same thermal load. | Pumps require energy, though far less than fans. Mitigation: Use high-efficiency variable-speed pumps. |

| Cost (CAPEX/OPEX) | Lower operational costs (OPEX) due to energy savings and higher reliability. | Higher initial hardware cost (CAPEX). Mitigation: Conduct a Total Cost of Ownership (TCO) analysis to justify the investment. |

| System Complexity | Allows for flexible heat rejection (radiator can be placed remotely). | More components (pumps, tubes, radiator). Mitigation: Partner with a one-stop manufacturer who can provide integrated solutions. |

| Reliability & Maintenance | Increased component lifespan due to stable, low operating temperatures. | Perceived risk of leaks; fluid may need periodic checks. Mitigation: Use robust manufacturing (FSW/Brazing) and 100% pressure testing. |

Liquid Cold Plates vs. Air Cooling: A Head-to-Head Showdown

When compared directly, liquid cold plates dramatically outperform even the most advanced air cooling systems. The fundamental properties of liquid make it a vastly superior medium for heat transfer, resulting in lower thermal resistance, higher heat flux capacity, and greater design freedom. While air cooling has its place, the data clearly shows that for high-power applications, liquid cooling is in a class of its own.

Comparing Key Performance Metrics

The most critical metric in thermal management is thermal resistance—the lower, the better. A high-performance air cooler (a large heat sink with a powerful fan) might achieve a thermal resistance of 0.15 °C/W. A well-designed liquid cold plate, however, can easily achieve a resistance of 0.05 °C/W or lower. This means for the same amount of heat, the component will stay significantly cooler.

This directly impacts the maximum heat flux capacity. Air coolers struggle to handle heat fluxes above 50 W/cm². Liquid cold plates, on the other hand, are routinely designed to manage fluxes of 200 W/cm² or more, making them the only viable option for modern, high-density processors and power modules.

Space, Weight, and Design Freedom

To match the performance of a compact liquid cold plate, an air cooling system would be enormous. The required heat sink would be several times larger and heavier, and it would need a loud, power-hungry fan. This is often impractical or impossible in space-constrained designs like blade servers or EV battery packs.

Liquid cooling decouples the heat absorption (at the cold plate) from the heat rejection (at the radiator). This gives engineers incredible design freedom. The cold plate can be small and lightweight, while the radiator can be placed anywhere in the system where there is space and airflow.

The Long-Term Cost and Reliability Argument

While the initial cost of an air cooler is lower, the long-term value proposition often favors liquid cooling. The superior energy efficiency of pumps over fans leads to **lower operational costs**. More importantly, by keeping components at a lower and more stable temperature, liquid cooling **increases their reliability and lifespan**, reducing the risk of costly field failures and warranty claims. This makes it a smarter investment for mission-critical applications.

| Metric | Air Cooling (High-Performance Heat Sink) | Liquid Cold Plate |

|---|---|---|

| Thermal Resistance | Moderate (e.g., ~0.15 °C/W) | Very Low (e.g., <0.05 °C/W) |

| Heat Flux Capacity (W/cm²) | Low (Up to ~50 W/cm²) | Very High (200+ W/cm²) |

| Size & Weight for Equivalent Performance | Large and Heavy | Compact and Lightweight |

| Energy Efficiency (PUE) | Lower Efficiency | Higher Efficiency |

| Noise Level | High (Loud Fans) | Very Low (Quiet Pumps) |

How Are High-Performance Liquid Cold Plates Made? A Look Inside the Factory

High-performance liquid cold plates are created using a range of sophisticated manufacturing processes, each chosen to balance performance, cost, and design complexity. From foundational methods like embedding tubes into a baseplate to advanced techniques like vacuum brazing and Friction-Stir Welding (FSW), the process determines the cold plate’s internal structure, thermal efficiency, and reliability. Understanding these factory processes is key to selecting a technology that truly matches your application’s demands.

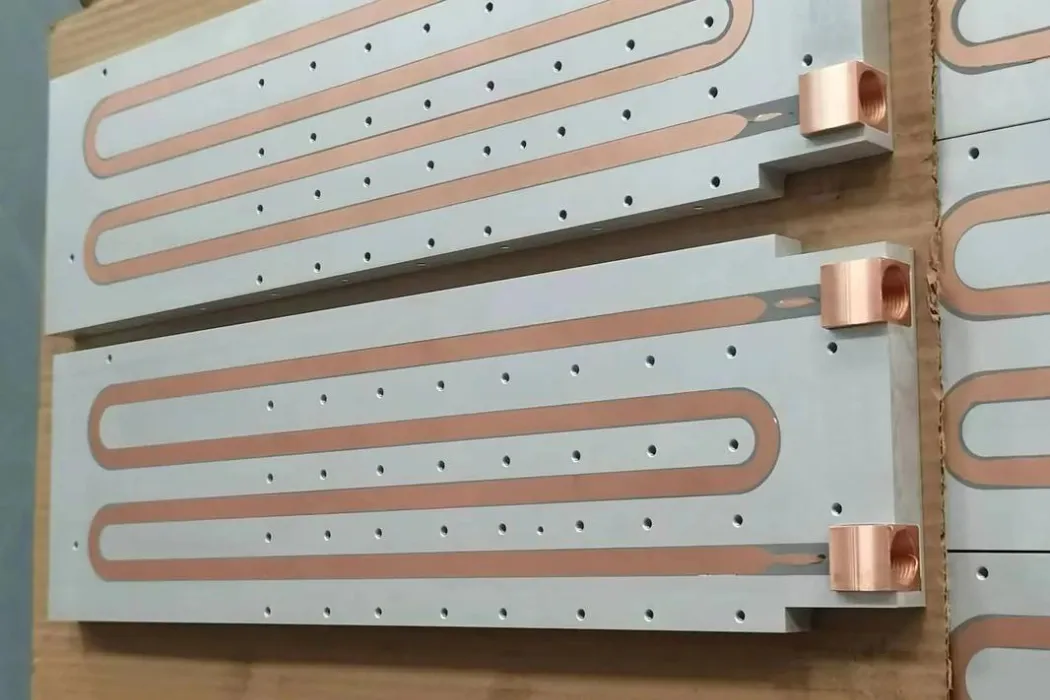

The Foundation: Tubed Cold Plates (Press-Fit & Epoxy)

This is one of the most traditional and flexible methods for creating a liquid cold plate. The process is straightforward: grooves are machined into a metal baseplate (usually aluminum or copper), and a continuous tube (usually copper or stainless steel) is pressed into these grooves. Two main variations exist:

- Press-Fit: The tube is mechanically forced into the groove under high pressure. This creates a good mechanical bond, but microscopic air gaps can remain, leading to higher thermal resistance.

- Epoxied: After placing the tube in the groove, a highly conductive thermal epoxy is used to fill any remaining voids. This improves the thermal transfer compared to a simple press-fit and enhances the structural bond.

Tubed cold plates are an excellent choice for **prototypes and low-volume applications** because they require minimal tooling and can be easily customized. However, the thermal interface between the tube and the plate creates a point of thermal resistance, limiting their effectiveness for very high heat flux applications.

For High Volume: Die-Cast & Extruded Cold Plates

When producing thousands of identical parts, die-casting and extrusion offer significant cost advantages.

- Die-Casting: This process involves injecting molten aluminum into a steel mold (a die) under high pressure. It can create complex internal flow paths and mounting features in a single step, drastically reducing the need for post-machining. This makes it ideal for **high-volume automotive applications**. The main challenge is managing potential porosity (tiny air bubbles) in the casting, which can affect leak-proof integrity.

- Extrusion: Similar to heat sink manufacturing, a billet of aluminum is pushed through a die to create a long part with a consistent cross-section of internal channels. This long extrusion is then cut to length, and the ends are sealed to create a simple, effective cold plate. This method is **very cost-effective** but is limited to simple, straight flow paths.

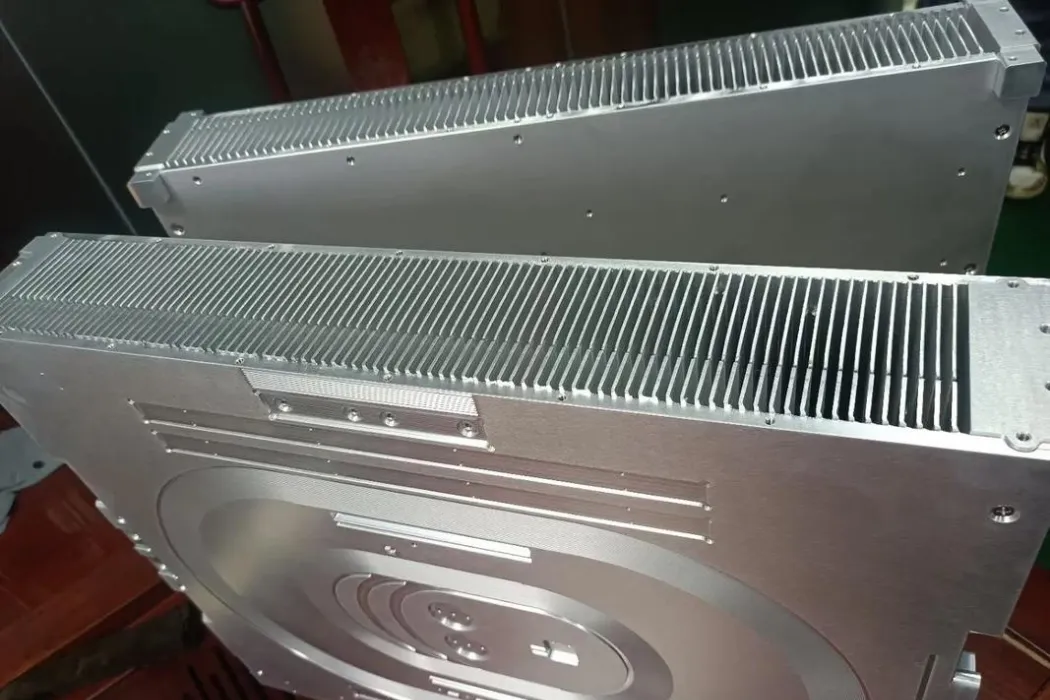

The High-Performance Standard: Vacuum Brazed Cold Plates

For applications demanding high thermal performance and complex internal structures, vacuum brazing is the gold standard. This process involves assembling multiple layers of machined metal components (a base plate, a cover, and often an internal fin structure) with a brazing alloy placed between them. The entire assembly is then heated in a vacuum furnace.

The vacuum prevents oxidation, and the heat melts the alloy, creating **perfect, void-free metallurgical bonds** between all components. This technique allows for the creation of intricate, high-surface-area internal fins that dramatically improve heat transfer. It is a core competency at Walmate Thermal, enabling us to produce **highly efficient cold plates for data centers and power electronics**.

Vacuum brazing creates a monolithic metal block with complex internal channels. The result is a cold plate with extremely low thermal resistance and excellent reliability, as there are no mechanical joints or epoxies that can degrade over time.

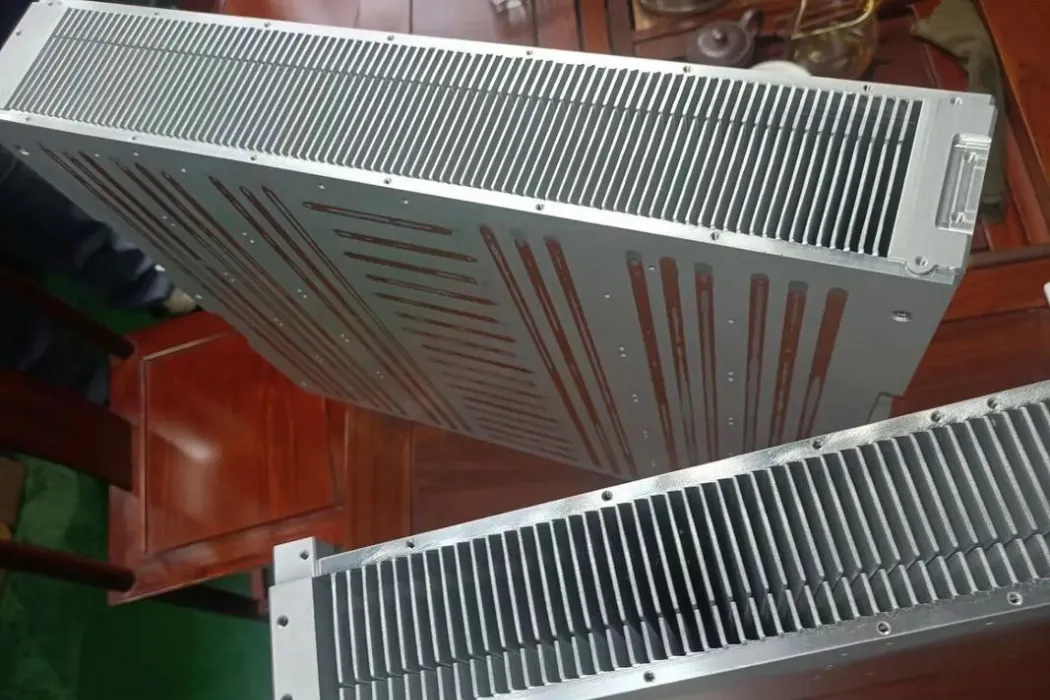

The Ultimate in Durability: Friction-Stir Welded (FSW) & Gun Drilled Cold Plates

When absolute reliability and durability are non-negotiable, FSW and gun drilling are the leading technologies.

- Friction-Stir Welding (FSW): This is an advanced, solid-state joining process. A rotating tool is used to “stir” the metal of two separate pieces together, creating a seamless, high-strength weld without melting the material. To make a cold plate, a channel is machined into a base plate, and a lid is placed on top. The FSW tool then seals the perimeter, creating an incredibly strong, leak-proof joint. This is Walmate Thermal’s preferred method for **mission-critical applications like EV battery trays**, where long-term reliability is paramount.

- Gun Drilling: This method is used to create long, perfectly straight fluid channels deep inside a solid block of metal. It’s a precise process borrowed from the firearms industry. Gun-drilled cold plates are exceptionally robust as they are made from a single piece of material, but they are limited to simple, straight-line flow paths.

Precision Matters: The Role of CNC Machining in All Processes

It’s important to recognize that CNC (Computer Numerical Control) machining is not just a standalone method; it is a crucial supporting technology for nearly every process described above. From carving the initial channels for tubed cold plates to creating the intricate fin structures for brazed assemblies and ensuring the perfect flatness of an FSW lid, precision machining is essential. The final flatness of the mounting surface, typically achieved through a process called fly-cutting, is one of the most critical factors for ensuring low thermal resistance between the cold plate and the component it is cooling.

What Are the Different Types of Liquid Cold Plates? A Complete Breakdown

Choosing the right liquid cold plate requires understanding the vast landscape of available technologies. Each type is born from a specific manufacturing process, offering a unique profile of performance, cost, and design flexibility. From simple and cost-effective extruded plates to ultra-reliable FSW and high-performance brazed assemblies, the ideal choice depends entirely on your project’s specific thermal, mechanical, and commercial goals. This breakdown will cover the entire spectrum of modern cold plate technologies.

Tubed Cold Plates

As one of the most established technologies, a tubed cold plate involves embedding a continuous metal tube into a machined channel on a base plate. This method offers excellent design flexibility, as the tube path can be customized to target specific hot spots on a device. It is particularly well-suited for applications with multiple, distributed heat sources. The primary limitation is the thermal resistance at the interface between the tube and the plate, which can limit its peak performance compared to monolithic designs. It remains a top choice for **prototyping and applications where custom flow paths are a priority**.

Die-Cast & Extruded Cold Plates

These two technologies are all about **scalability and cost-efficiency for high-volume production**.

- Die-Cast Cold Plates: By injecting molten aluminum into a mold, die-casting can produce complex, near-net-shape parts with internal channels in a single step. This dramatically reduces machining time and cost per part, making it a favorite in the **automotive industry**. The trade-off is the high initial tooling cost and the need for rigorous quality control to prevent porosity that could lead to leaks.

- Extruded Cold Plates: This process creates long sections of aluminum with built-in, straight-line channels. These sections are then cut to size and sealed. It is an extremely cost-effective method for simple applications that do not require complex flow paths. They are often used in **industrial power electronics** where a simple, linear cooling path is sufficient.

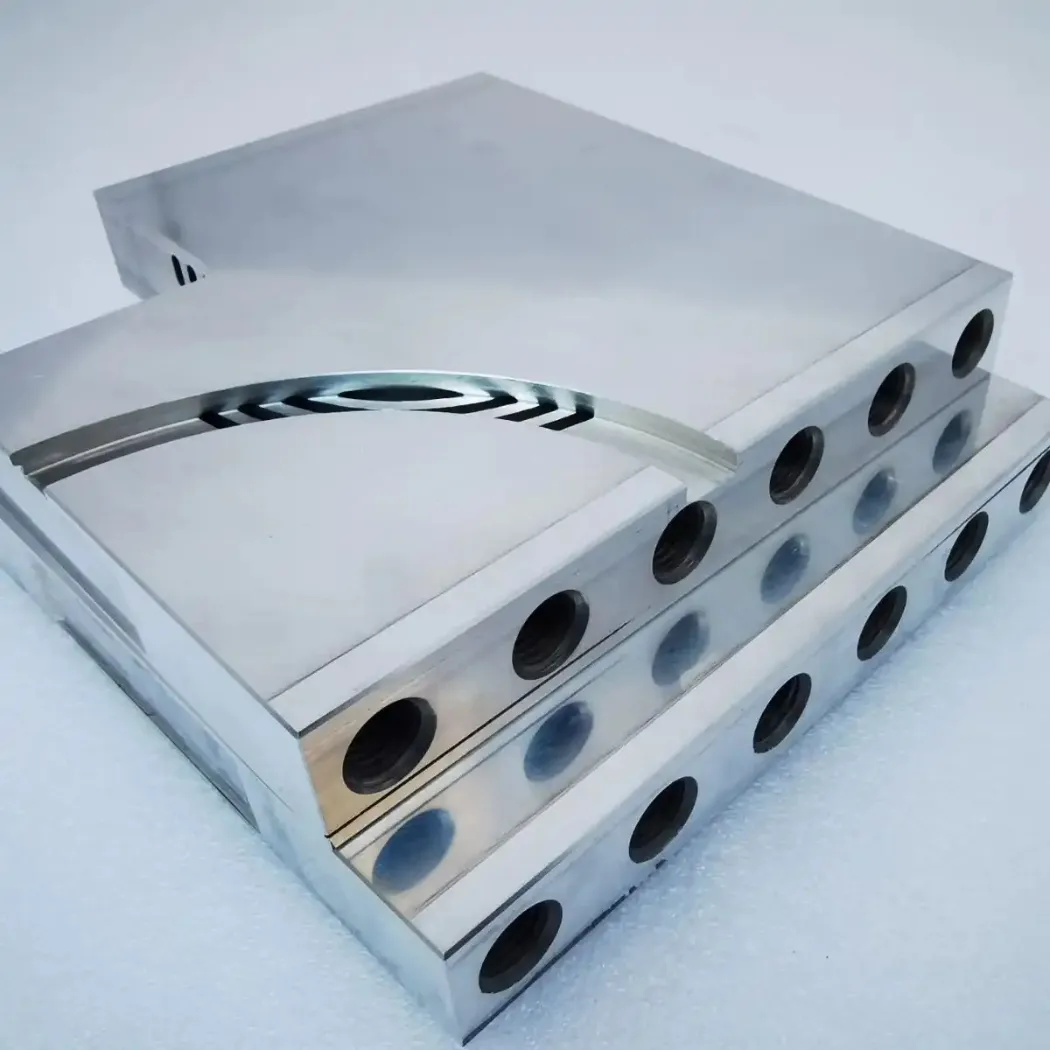

Gun Drilled Cold Plates

For applications demanding extreme ruggedness and reliability, gun drilling is a unique solution. This process drills a precise, straight-line channel through a solid block of metal. Because it is made from a single, monolithic piece, there are **no joints, welds, or seams that could potentially leak**. This makes it exceptionally durable and suitable for high-pressure applications. However, the design is limited to straight flow paths, and it is a slower, more expensive process than extrusion, making it best for **specialized industrial or military applications** where reliability is the absolute top priority.

Brazed Cold Plates with Internal Fins

When **maximum thermal performance** is the primary goal, brazed cold plates are often the answer. This technology uses a multi-part assembly—typically a base plate, a top lid, and a high-density internal fin stack. These components are joined together in a vacuum furnace using a brazing alloy.

The result is a monolithic part with a vast internal surface area, thanks to the fins. This design creates more turbulence in the fluid and provides more area for heat transfer, significantly lowering the plate’s thermal resistance. It is the preferred technology for **cooling high-end data center CPUs, GPUs, and powerful laser diodes** where every degree of temperature matters.

Friction-Stir Welded (FSW) Cold Plates

FSW technology offers a best-of-both-worlds solution, combining **high thermal performance with unmatched durability and reliability**. A channel is machined into a solid base plate, which can contain complex features like fin structures. A lid is then placed on top and joined using Friction-Stir Welding, a solid-state process that creates a seamless, void-free bond stronger than the parent material itself.

Because there is no melting involved, the FSW process avoids the stresses and potential defects associated with traditional welding. This makes it the **gold standard for mission-critical applications like EV battery cooling and aerospace electronics**, where long-term, leak-proof reliability is non-negotiable.

Skived Fin & Stamped Fin Cold Plates

These types focus on creating high surface area on the fluid side of the equation. A **skived fin** cold plate is made by precisely cutting thin fins from a solid block of copper or aluminum and then bending them upwards. These fins are then enclosed within a housing to form the flow path. **Stamped fins** are manufactured separately and then brazed or bonded to a base plate. Both methods create a high density of fins to maximize heat transfer, making them suitable for compact, high-performance applications, although brazed assemblies are generally more common for complex cold plates.

| Technology Type | Thermal Performance | Best Use Case | Cost Profile | Design Complexity | Key Advantage |

|---|---|---|---|---|---|

| Tubed (Press-Fit/Epoxy) | Good | Prototyping, multi-hotspot cooling | Low-Medium | High (Flexible) | Flow Path Customization |

| Die-Cast | Good | High-volume automotive | Very Low (at scale) | High (Tooling) | Low Part Cost |

| Extruded | Moderate | Simple industrial cooling | Very Low | Very Low | Lowest Cost |

| Gun Drilled | Good | High-pressure, rugged applications | High | Low | Extreme Durability |

| Vacuum Brazed | Excellent | Data centers, lasers, high-TDP electronics | Medium-High | High (Complex) | Peak Performance |

| Friction-Stir Welded (FSW) | Excellent | EV batteries, aerospace, mission-critical | Medium-High | High (Complex) | Unmatched Reliability |

How Do You Choose the Right Liquid Cold Plate? A 4-Step Engineering Process

Selecting the optimal liquid cold plate is not about picking a part from a catalog; it’s a systematic engineering process. A successful outcome requires a clear definition of requirements, careful material selection, and a deep understanding of manufacturing trade-offs. This 4-step process will guide you from initial concept to a production-ready solution, ensuring you achieve the perfect balance of performance, cost, and reliability for your specific application.

Step 1: Define Your Key Thermal & Mechanical Requirements

Before you can design a solution, you must first define the problem. This begins with a thorough audit of your system’s requirements. Rushing this step is the most common cause of project delays and budget overruns. Your essential checklist should include:

- Heat Load (Watts): What is the total thermal power your device generates that needs to be dissipated?

- Maximum Component Temperature (Tmax): What is the highest temperature your component can safely operate at? This is a hard limit that dictates the entire design.

- Fluid Type and Inlet Temperature: What type of coolant will you be using (e.g., water, water/glycol)? What is its temperature as it enters the cold plate?

- Maximum Flow Rate & Pressure Drop: What are the capabilities of your pump? Your cold plate’s internal geometry must be designed to not exceed the maximum allowable pressure drop at your target flow rate.

- Mechanical Constraints: What is the physical footprint (length, width, height) available for the cold plate? Where are the mounting points and fluid inlet/outlet ports located?

Step 2: Which Material is Best? Aluminum vs. Copper vs. Stainless Steel

The material of your cold plate is one of the most critical design choices, directly impacting thermal performance, weight, and cost. There is no single “best” material; the right choice is always a trade-off based on your specific priorities.

While copper offers the highest thermal conductivity, making it ideal for absorbing high heat fluxes, aluminum provides an excellent balance of good performance, light weight, and lower cost, making it the most common choice. Stainless steel is typically reserved for applications where corrosion resistance or fluid compatibility is the primary concern, despite its lower thermal performance.

| Material | Thermal Conductivity (W/mK) | Weight (Density g/cm³) | Corrosion Resistance | Relative Cost |

|---|---|---|---|---|

| Aluminum (6061) | ~167 | 2.70 | Good (Excellent with coating) | $$ |

| Copper (C110) | ~385 | 8.96 | Good | $$$$ |

| Stainless Steel (304) | ~16 | 8.00 | Excellent | $$$ |

Step 3: The Critical Role of Thermal Simulation (CFD) for Design Validation

In modern engineering, you should never have to guess. Before any metal is cut, **Computational Fluid Dynamics (CFD) simulation** is used to create a digital twin of your proposed cold plate design. This powerful software models the flow of the liquid and the transfer of heat, allowing engineers to accurately predict the cold plate’s performance under real-world conditions.

At Walmate Thermal, CFD analysis is a **standard part of our custom design process**. It allows us to optimize internal fin structures, fine-tune flow paths, and validate that the design will meet your required thermal resistance and pressure drop targets. This **design-simulate-iterate** loop saves enormous amounts of time and money by eliminating the need for costly and slow physical prototyping cycles.

Step 4: Balancing Performance with Cost for Manufacturing at Scale

The perfect cold plate for a single prototype may not be the right choice for a product that will be manufactured in the thousands. The final step is to balance your performance needs with your target cost and production volume. For example:

- A fully CNC-machined prototype offers maximum design freedom but is expensive for mass production.

- A die-cast design has a high initial tooling cost but a very low per-unit cost at high volumes.

- A brazed or FSW assembly might offer the best blend of high performance and reasonable cost at medium to high volumes.

This is why it is crucial to partner with a manufacturer that offers a full range of capabilities. As your project moves from prototype to production, we can help you transition from one manufacturing process to another, optimizing your design for cost and scalability without sacrificing performance.

What Are the Key Applications Driving Cold Plate Innovation?

The explosive demand for liquid cold plates is driven by several key industries, all pushing the limits of power and performance. From ensuring the safety and range of electric vehicles to enabling the next wave of artificial intelligence in data centers, cold plates are the core enabling technology. They also play a critical role in providing the precision thermal control needed for medical lasers and the rugged reliability required by industrial power electronics.

Electric Vehicles (EV) & Energy Storage (ESS)

The performance, longevity, and safety of a lithium-ion battery pack are all directly tied to its ability to maintain a stable, optimal temperature. During fast charging and high-power discharging, a battery module can generate an enormous amount of waste heat.

Liquid cold plates, particularly large-format **Friction-Stir Welded (FSW) aluminum plates**, are the definitive solution. They are integrated directly into the battery pack architecture, with coolant channels serpentining between the battery cells to absorb heat uniformly. This precise thermal management is critical for:

- Maximizing Battery Lifespan: Preventing overheating, which is a primary cause of battery degradation.

- Enabling Faster Charging: Safely dissipating the intense heat generated during DC fast charging.

- Ensuring Safety: Reducing the risk of thermal runaway by keeping cell temperatures in a safe operating range.

Data Centers & AI Clusters

The artificial intelligence revolution is built on processors that are incredibly powerful and incredibly hot. The TDP of top-tier GPUs and CPUs has soared past 1,000 watts, a level of heat flux that air cooling simply cannot handle. This has made **direct-to-chip liquid cooling** the new standard for high-performance computing.

In this application, high-performance **vacuum brazed cold plates** with dense internal copper fins are mounted directly onto the processors. This approach allows data center operators to cool entire racks generating 100 kW or more of heat, a feat unimaginable with air. The benefits include eliminating performance throttling, increasing rack density, and drastically lowering the facility’s energy consumption (PUE).

Medical & Industrial Lasers

High-power laser systems, whether used for medical surgery or industrial cutting, require extreme temperature stability. Even a minor temperature fluctuation in the laser diode or its optics can cause a shift in wavelength, leading to a loss of performance and accuracy.

Liquid cold plates provide the active, precise temperature control necessary for these sensitive applications. By circulating a temperature-controlled fluid, they can maintain a component’s temperature within a fraction of a degree, ensuring consistent and reliable operation for systems where precision is paramount.

Power Electronics & Variable Frequency Drives (VFDs)

In industrial settings, power electronics like IGBTs, MOSFETs, and VFDs control massive amounts of electrical power. The heat generated during this process is substantial, and if not managed properly, leads to premature failure. Reliability is everything in these applications, as downtime can cost a factory thousands of dollars per minute.

Rugged, custom-designed liquid cold plates ensure these critical components remain cool and reliable even in harsh industrial environments. By efficiently removing heat, they extend the lifespan of the power modules, improve system efficiency, and ensure the continuous, predictable operation that modern industry depends on.

Why Should You Partner with a Custom Cold Plate Manufacturer?

Partnering with a specialized custom cold plate manufacturer is crucial because it transforms a complex thermal challenge into a reliable, scalable, and cost-effective product. An expert partner acts as an extension of your engineering team, guiding you from initial design and simulation to rigorous testing and high-volume production. This strategic partnership de-risks your project, accelerates your time-to-market, and ensures your final product meets its performance goals without compromise.

From Concept to Production: The Power of a One-Stop Solution

Developing a custom cold plate involves multiple stages: thermal design, mechanical engineering, simulation, prototyping, testing, and mass production. Managing separate vendors for each of these stages is inefficient, risky, and slow. A true **one-stop solution** partner, like Walmate Thermal, integrates all these capabilities under one roof.

This approach offers significant advantages. Our engineers who design the cold plate also understand the manufacturing process, ensuring the design is optimized for scalability and cost from day one. This **Design for Manufacturing (DFM)** philosophy prevents costly redesigns later. A single point of contact simplifies communication, streamlines the supply chain, and ensures a seamless transition from a single prototype to tens of thousands of units per month.

Are Quality Certifications Like IATF 16949 Important for Your Project?

Absolutely. Even if your project is not automotive-related, a certification like **IATF 16949** is a powerful indicator of a manufacturer’s commitment to quality. This global automotive quality standard is one of the most stringent in the world. It goes far beyond basic quality checks.

A manufacturer with IATF 16949 certification demonstrates rigorous process control, complete material traceability, a culture of continuous improvement, and a robust risk management framework. It is your assurance that every cold plate you receive—whether it’s the first or the ten-thousandth—is built to the exact same high standard.

The Importance of Prototyping and Validation Testing

A successful project always ends with rigorous validation. While CFD simulation is essential for optimizing a design, a physical prototype is necessary to validate its real-world performance. An expert manufacturing partner will have a rapid prototyping process to get a functional part in your hands quickly.

Once the prototype is approved, every production part must undergo a series of tests to guarantee its integrity. This includes 100% leak testing under pressure and thermal performance validation to ensure it meets the specifications determined during the design phase. This final quality gate is non-negotiable for any mission-critical application and is a standard procedure for all custom parts from Walmate Thermal.

Frequently Asked Questions (FAQs)

-

1. What is the difference between a liquid cold plate and a heat sink?

- A heat sink transfers heat from a component to the surrounding air (air cooling). A liquid cold plate transfers heat from a component to a liquid that is pumped through it (liquid cooling). Liquid cooling is significantly more powerful and efficient.

-

2. How do you ensure a liquid cold plate won’t leak?

- Reliability comes from advanced manufacturing and rigorous testing. At Walmate Thermal, we use robust joining methods like Friction-Stir Welding (FSW) and vacuum brazing to create seamless, monolithic parts. Most importantly, every single cold plate we produce undergoes 100% pressure and leak testing before shipping.

-

3. What fluids are typically used with liquid cold plates?

- The most common fluid is a mixture of deionized water and ethylene or propylene glycol. The glycol acts as both an antifreeze and an anti-corrosive/biocidal agent. Specialized dielectric fluids are also used in certain applications.

-

4. Is a copper cold plate always better than an aluminum one?

- Not necessarily. Copper has superior thermal conductivity, making it better for absorbing very high heat fluxes. However, aluminum offers an excellent balance of good performance, lighter weight, and lower cost. The best choice depends on the specific priorities of your project.

-

5. What is the typical lead time for a custom cold plate prototype?

- While this varies with complexity, our streamlined processes allow for rapid prototyping. We can often deliver custom CAD drawings within 2 weeks and produce functional prototypes shortly after, helping you accelerate your development cycle.

-

6. What is the difference between a brazed and an FSW cold plate?

- A brazed cold plate is ideal for creating complex internal fin structures for maximum thermal performance. An FSW cold plate is known for its extreme durability and reliability, making it the top choice for applications like EV batteries where long-term, leak-proof integrity is paramount.

-

7. Do you have a minimum order quantity (MOQ) for custom designs?

- No. At Walmate Thermal, we have no minimum order quantity. We are equipped to support your project whether you need a single prototype for validation or tens of thousands of units for mass production.

-

8. Can you help me design a cold plate if I only have the basic requirements?

- Yes, absolutely. Our engineering team specializes in this. If you can provide your key requirements (heat load, max temperature, dimensions), we can provide a complete, one-stop service that includes thermal simulation, design, prototyping, and manufacturing.

Conclusion: The Foundation for High-Power Innovation

As we’ve journeyed through the world of liquid cold plates, one thing is clear: as power densities continue to soar, this technology has evolved from a niche component into an essential foundation for modern innovation. From the design of the internal channels to the choice of manufacturing process, every decision impacts performance. In this high-stakes environment, choosing the right design and, just as importantly, the right manufacturing partner is critical to success.

An off-the-shelf solution is almost always a compromise. To achieve the optimal performance, absolute reliability, and long-term cost-effectiveness your product demands, a **custom-engineered cold plate** is the only answer. A solution validated by rigorous simulation and proven by physical testing is not a luxury—it’s a necessity for competing at the highest level.

Don’t let thermal limits dictate the future of your innovation.

Walmate Thermal is your end-to-end partner for high-performance liquid cold plates. We combine advanced design and simulation with a full suite of manufacturing capabilities—from brazing to FSW—all under one roof.Contact our engineering team for a 24-hour quote. Let’s design and build the perfect thermal solution for your next-generation product, with no minimum order quantity.