The popularization of humanoid robots relies on the stable output of core performance, and thermal management technology is the “invisible cornerstone” ensuring their continuous and efficient operation. This article focuses on the uniqueness of humanoid robot thermal management, analyzes key challenges such as space constraints and dynamic heat loads under human-like structures, systematically sorts out heat dissipation technical paths adapted to humanoid scenarios, and highlights Walmate Thermal’s technical practice in the field of heat pipe heat sinks. It explores their application schemes in humanoid robots and summarizes core design principles for thermal management systems, providing engineering-oriented reference for related research and development.

1. Introduction

As humanoid robots move from laboratories to factory workshops and household scenarios, their operational stability becomes critical for practical adoption. Unlike industrial robotic arms with fixed working conditions, humanoid robots need to mimic human movements such as walking, grasping, and carrying loads, meaning internal components like motors, driver chips, and sensors must operate under frequent start-stop cycles and fluctuating loads. During the conversion of electrical energy to mechanical energy, approximately 20%-30% of energy is converted into heat. If not dissipated in a timely manner, this heat can cause motor torque reduction, chip computing delays, or even fatal failures such as magnet demagnetization and circuit burnout. Thus, thermal management is not only a technical issue but also a core factor determining the practical value of humanoid robots. As a high-efficiency heat transfer carrier, heat pipe heat sinks play an irreplaceable role in this process. WALMATE, a leader in thermal management, provides reliable heat dissipation support for precision equipment like humanoid robots through its high-performance heat pipe heat sinks.

2. Key Challenges in Humanoid Robot Thermal Management

2.1 Contradiction Between Space and Power Density

To achieve human-like flexible movement, humanoid robot joints require compact and lightweight internal structures. Take the elbow joint as an example: it typically integrates motors, harmonic reducers, and torque sensors, leaving less than 1/3 of the space for heat dissipation devices compared to conventional industrial motors. However, to achieve load-bearing capacity, joint motors must have high power density. For instance, a 5kg-class leg joint can reach a peak power of 800W, with heat generation per unit volume 5-8 times that of ordinary household motors, creating a sharp “high heat generation in limited space” contradiction. This places extreme demands on the volume, weight, and heat dissipation efficiency of heat pipe heat sinks. WALMATE’s miniaturized high-efficiency heat pipe heat sinks, designed specifically for such scenarios, leverage the high thermal conductivity of heat pipes to rapidly transfer and diffuse heat in confined spaces.

2.2 Uncertainty of Dynamic Heat Loads

The randomness of human daily movements leads to significant fluctuations in robot heat loads. Motor power consumption is only a few tens of watts when standing still, surges to hundreds of watts during fast walking, and may exceed peak levels during heavy lifting. This “intermittent bursts + continuous accumulation” heat characteristic requires heat dissipation systems to handle both short-term high-temperature shocks and long-term heat accumulation. Traditional fixed-size heat sinks struggle to adapt to dynamic temperature differences, but WALMATE’s heat pipe heat sinks, with their rapid thermal response, efficiently conduct heat during load fluctuations. Combined with optimized fin structures, they maintain stable heat dissipation efficiency across varying loads.

2.3 Heat Dissipation Obstacles from Human-Like Structures

The human-like closed structure of robot torsos and limbs hinders natural heat dissipation. For example, the chest cavity integrates main control chips and power modules but lacks natural convection channels; leg joints may contact clothing or the ground during movement, further blocking heat release. Additionally, joint rotation causes frequent component displacement, which can disrupt rigid traditional heat sinks. WALMATE’s flexible heat pipe heat sinks, combining bendable heat pipes with lightweight fins, adapt to ±180° joint rotation, effectively solving heat dissipation obstacles in dynamic movement scenarios.

2.4 Coupling Effects of Multiple Heat Sources

Internal heat sources in robots are not isolated: motor heat can transfer to adjacent reducers, affecting lubricant performance; high chip temperatures may interfere with sensor accuracy; and overlapping heat from power modules and motors can form local hotspots. This “thermal coupling effect” means a single heat dissipation failure can trigger连锁 reactions. Modular layouts of heat pipe heat sinks address this issue: WALMATE’s multi-branch heat pipe design connects different heat sources, concentrating scattered heat to the main dissipation area, effectively mitigating thermal coupling.

3. Heat Dissipation Technical Paths for Humanoid Scenarios

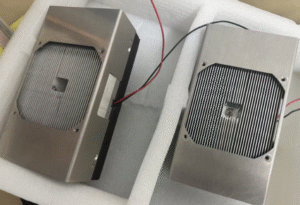

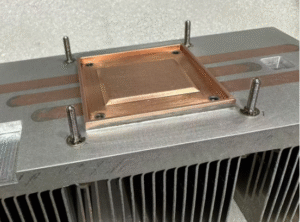

3.1 Structure-Optimized Air Cooling and High-Efficiency Heat Pipe Heat Sink Applications

To address space constraints, lightweight air cooling technology is advancing toward precision design, with heat pipe heat sinks as core components. Unlike traditional bulky heat sinks, WALMATE’s custom miniaturized heat pipe heat sinks combine high-thermal-conductivity aluminum fins with copper heat pipes, using 3D printing for an integrated structure. Heat pipe embedding density is 40% higher than traditional schemes, improving heat transfer efficiency by 50% in the same volume. Integrated into motor housings, these heat pipe heat sinks rapidly conduct core heat to fins via heat pipes, leveraging airflow from joint movement for natural cooling. In fixed areas like the torso, heat pipe heat sinks are paired with ultra-thin centrifugal fans (only 5mm thick) and serpentine air ducts to direct heat to rear or bottom cooling grilles. A service robot equipped with WALMATE’s optimized heat pipe heat sinks achieved a 40% improvement in shoulder motor cooling efficiency, with 20% weight reduction and noise controlled below 45 decibels.

3.2 Synergy Between Intelligent Phase Change Buffering and Heat Pipe Heat Sinks

Phase change materials (PCMs), acting as “heat sponges,” excel at handling dynamic heat shocks, and their synergy with heat pipe heat sinks enhances performance. WALMATE encapsulates paraffin-based PCMs into thin sheets (2-3mm thick) attached to the evaporator section of heat pipe heat sinks. When temperatures reach the phase change point (typically 55-65°C), the material melts from solid to liquid, absorbing large amounts of latent heat to slow temperature rise. Simultaneously, heat pipes rapidly conduct heat to finned condenser sections, forming a complete “buffering-conduction-dissipation” cycle. At low loads, passive cooling relies on PCMs and heat pipe heat sinks; at high loads, auxiliary fans activate to enhance airflow. Experimental data shows this synergy reduces short-term overload temperature peaks of joint motors by 15-20°C.

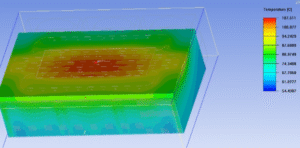

3.3 Auxiliary Cooling Through Material Innovation

New materials enhance heat pipe heat sink performance: WALMATE adds nano-thermal particles to heat pipe working fluids, increasing thermal conductivity by 25%; fin surfaces are treated with hydrophilic coatings to improve condensation efficiency; graphene thermal interface materials between heat pipe heat sinks and heat sources reduce contact thermal resistance to below 0.01°C·cm²/W. These innovations unlock greater heat dissipation potential for humanoid robot therml management.We conduct thermal analysis using professional thermal simulation analysis software to determine the optimal size and structure of the heat sink

4. Case Studies: Integrated Applications of WALMATE Heat Pipe Heat Sinks

4.1 Full-Body Thermal Management for Bipedal Robots

A 1.5-meter-tall bipedal robot adopted WALMATE’s “zoned management + intelligent linkage” thermal solution: high-load leg joints (hips, knees) use custom heat pipe heat sinks, where multiple micro heat pipes transfer motor stator heat to external cooling fins, augmented by directional micro fans; arm joints, with lower loads, use WALMATE’s lightweight heat pipe heat sinks combined with PCMs for passive cooling; internal torso components (main control units, power modules) connect to custom-shaped heat pipe heat sinks and air ducts, with heat pipes guiding heat through structural parts to rear cooling grilles, regulated by temperature-sensing fans. Equipped with 16 temperature sensors, the system monitors key components in real time. When joint temperatures exceed thresholds, auxiliary fans for corresponding heat pipe heat sinks automatically increase speed, achieving dynamic “cooling-performance” balance. During a 3-hour continuous walking test, all components maintained safe temperatures with no performance degradation.

4.2 Iterative Optimization of Joint Cooling Structures

A research team addressed ankle overheating in robots using WALMATE’s solutions: the first-generation design with traditional aluminum heat sinks reached 78°C after 1 hour of continuous load-bearing walking, causing卡顿; the second generation added micro fans but suffered excessive noise and limited efficiency gains; the final solution integrated three WALMATE technologies: 3D-printed micro-channel heat pipe heat sinks in motor housings, internal PCM filling, and optimized fin structures. Post-improvement, temperatures dropped to 56°C under the same conditions, weight decreased by 15%, and continuous operation time extended to over 4 hours, fully resolving overheating issues.

5. Core Design Principles for Humanoid Robot Thermal Management

5.1 Prioritize “Space Efficiency”

All cooling solutions must comply with humanoid structural constraints. WALMATE’s heat pipe heat sinks use integrated, lightweight designs: heat pipes are integrated with motor end caps, and heat pipe heat sink fins double as structural reinforcements to avoid extra space usage; flexible bendable heat pipes adapt to joint movement, ensuring efficient cooling in confined spaces.

5.2 Follow “Dynamic Adaptation” Logic

Cooling systems must match dynamic robot load characteristics. WALMATE’s heat pipe heat sinks, with rapid thermal response, include sufficient cooling margins for multi-mode regulation: passive cooling via heat pipe heat sinks and PCMs at low loads reduces energy consumption and noise; auxiliary fans activate at medium-high loads; overload protection triggers under extreme conditions to prioritize system safety over performance.

5.3 Adopt “System Synergy” Design

Thermal management is not an isolated module. WALMATE emphasizes deep integration of heat pipe heat sinks with overall robot design: heat pipe paths are planned during mechanical design to avoid movement interference, and fin layouts optimize airflow; temperature monitoring and fan control are embedded in electrical systems, with heat pipe heat sink temperature feedback integrated into control algorithms for a “structure-electrical-control” integrated thermal management system.

6. Conclusion

The core challenge of humanoid robot thermal management lies in addressing dynamic heat loads within human-like structural constraints. This requires performance innovations in high-efficiency cooling components like heat pipe heat sinks, combined with integrated system design and intelligent regulation. WALMATE, a leader in thermal management, delivers reliable cooling solutions for humanoid robots through optimized heat pipe layouts, fin structures, and material selection for heat pipe heat sinks and liquid cooling plates

As humanoid robots advance toward higher power, longer working and more complex scenarios, thermal management will evolve toward “higher efficiency, greater compactness, and smarter operation.” As a core carrier, heat pipe heat sink performance improvements will directly drive progress in humanoid robot thermal management. WALMATE will continue exploring new materials, structures, and control strategies to solve thermal challenges in precision equipment like humanoid robots, supporting the booming development of the humanoid robot industry. Any requirements can be sent to us via email, and we will reply within 8 hours. Our business email selena@walmatethermal.com