What is the TIG welding?

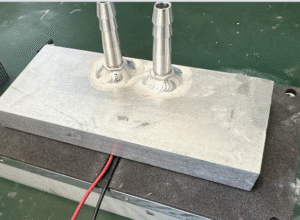

In the production chain of liquid cooling plates, there is a process that acts like an “invisible guardian,” silently protecting the core performance and safety of the equipment—this is the TIG (Tungsten Inert Gas) welding process. Especially in the welding of inlet and outlet nozzles of liquid cooling plates, the technical level directly affects the equipment’s operational efficiency, service life, and even safety stability, making it a crucial “lifeline project” that cannot be ignored in liquid cooling plate production.

As a device that relies on fluid media to transfer energy, the inlet and outlet nozzles of liquid cooling plates serve as the “throat” for medium circulation. Whether the medium flows smoothly inside the plate or there is a risk of leakage is almost entirely related to the welding quality of the inlet and outlet nozzles. TIG welding, with its unique process advantages, has become the optimal choice to ensure the quality of this critical link.

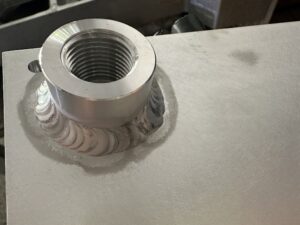

During the welding process, TIG welding forms a protective layer of inert gas (argon), isolating the welding area from the air. This characteristic effectively prevents gases such as oxygen and nitrogen in the air from reacting with high-temperature metals, thereby significantly reducing the occurrence of defects like pores and cracks in the weld. For the inlet and outlet nozzles of liquid cooling plates, the compactness of the weld is the core requirement to prevent medium leakage, and TIG welding perfectly meets this demand, providing solid support for the equipment’s sealing performance.

Meanwhile, TIG welding offers exceptional control over welding precision. During the process, the arc is stable and heat is concentrated, allowing welders to precisely control the size and shape of the molten pool, ensuring good fusion between the weld and the base material. The structure of liquid cooling plate inlets and outlets is often complex, with extremely high requirements for welding dimensional accuracy and appearance quality. TIG welding can meet these sophisticated requirements while ensuring welding strength, avoiding issues like welding deformation or dimensional deviations that could affect subsequent assembly and use.

From the perspective of long-term equipment operation, high-quality welds produced by TIG welding exhibit superior corrosion resistance and mechanical properties. The medium transported by liquid cooling plates may have certain corrosiveness, and the inlet and outlet nozzles, as the medium, are in a long-term environment of medium scouring and corrosion. The uniform and dense welds formed by TIG welding can effectively resist medium erosion, reduce corrosion wear at the welds, extend the equipment’s service life, and lower long-term maintenance costs.

In the production of liquid cooling plates, the welding quality of inlet and outlet nozzles directly determines product quality and market competitiveness. Once welding quality issues arise, they may cause medium leakage at best, affecting the normal operational efficiency of the equipment; at worst, they could lead to safety accidents, resulting in huge economic losses and negative impacts. TIG welding, with its reliable process performance, builds a solid defense line for the welding quality of inlet and outlet nozzles.

In summary, the TIG welding process plays a vital role in liquid cooling plate production, especially in the welding of inlet and outlet nozzles. It is not only a core process ensuring the sealing performance, precision requirements, and corrosion resistance of liquid cooling plates but also a key factor in improving product quality and ensuring safe and stable equipment operation. Emphasizing and continuously optimizing the TIG welding process holds immeasurable practical significance for liquid cooling plate manufacturers.