In today’s high-performance electronics landscape, thermal management has transformed from a back-of-the-box consideration to a mission-critical factor. As devices pack more power into smaller footprints—think data centers, EV inverters, and AI accelerators—the need for efficient, reliable cooling solutions has never been greater. Liquid cold plates have emerged as a frontrunner, offering compact designs and superior heat removal compared to traditional air-cooled methods. But choosing the right fluid is just as important as choosing the right plate: the wrong coolant can hamper performance, accelerate corrosion, or lead to costly downtime.

Liquid cold plates can utilize a range of fluids, including water-based mixtures with glycols and corrosion inhibitors, dielectric fluids such as fluorocarbons and synthetic esters, and specialized oils (mineral and synthetic). Each fluid type offers distinct trade-offs in thermal conductivity, electrical insulation, freeze protection, and material compatibility—making the selection process crucial for reliability and efficiency in electronics cooling applications.

Imagine a leading cloud provider racing to bring a new AI service online. Their engineers discovered that even a half-degree temperature rise could throttle performance across thousands of servers. By selecting an optimized coolant blend—tailored to resist freezing yet maximize heat transfer—they shaved energy costs, hit uptime targets, and secured a competitive edge. Intrigued? Let’s dive deeper into the fluids behind these game-changing results.

1. What Are Liquid Cold Plates and How Do They Work?

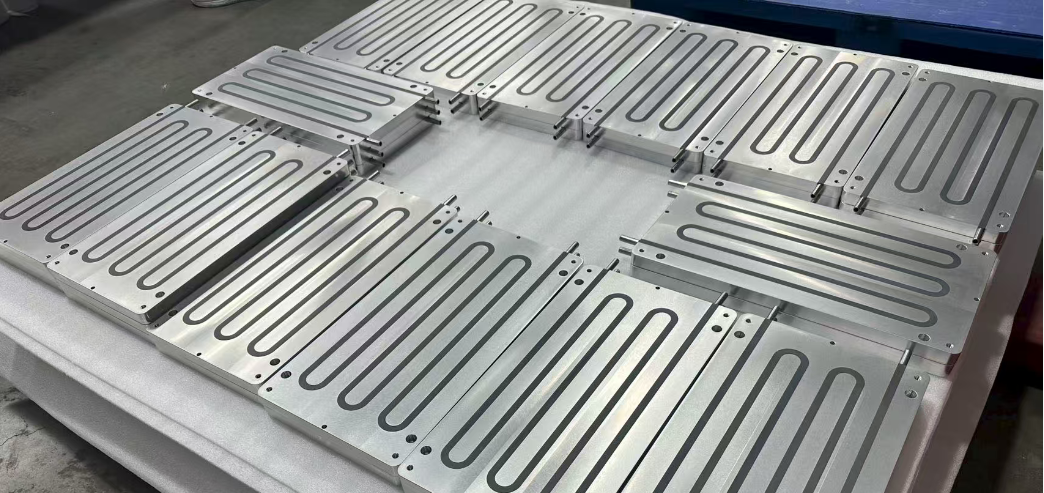

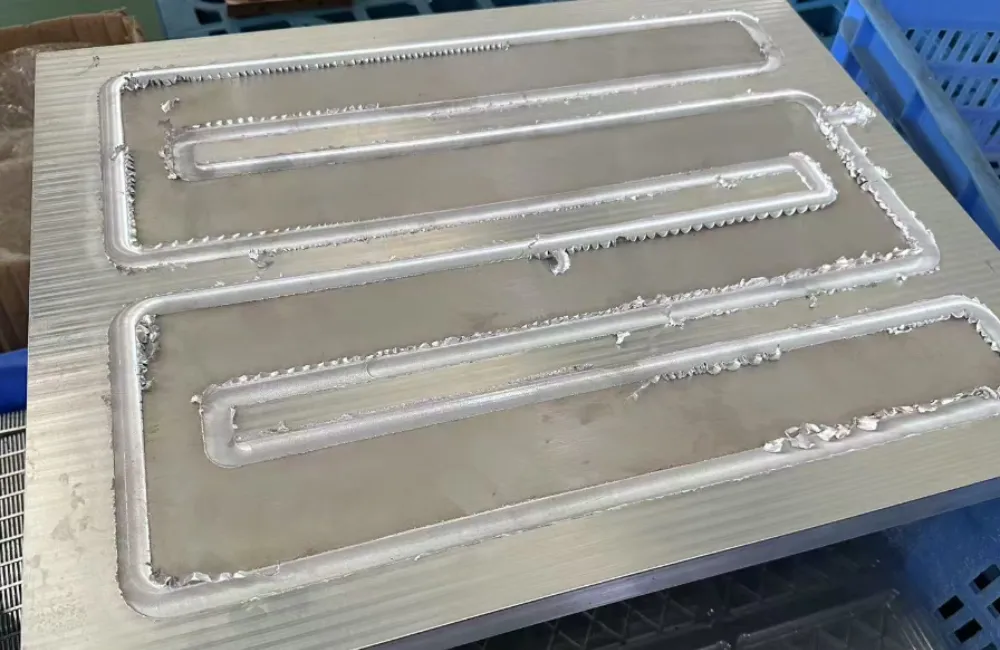

Liquid cold plates are flat heat exchangers that remove heat from electronic components by circulating a coolant through embedded channels or microchannels. As the fluid flows, it absorbs thermal energy from the plate’s surface, carrying it away to a heat exchanger or radiator. This direct-contact approach achieves higher heat transfer coefficients than air cooling, making cold plates ideal for high-power, high-density applications where temperature control and energy efficiency are paramount.

Let’s peel back the layers and explore what makes liquid cold plates tick, from their internal anatomy to why they outshine air-cooled alternatives in today’s performance-driven world.

Anatomy and Operating Principle

- Channel Geometry:

- Microchannels: Hundreds of etched or milled channels (0.2–1.0 mm wide) that maximize surface area

- Tubed Plates: Larger tubes (3–6 mm inner diameter) welded into a plate for moderate flow rates

- Brazed vs. Welded:

Type Pros Cons Brazed Cold Plate High thermal conductivity, leak-tight Higher tooling cost Welded Tubed Plate Flexible geometry, lower cost Slightly lower heat transfer - Material Selection:

- Aluminum: Lightweight, good thermal conductivity (~205 W/m·K), cost-effective

- Copper: Superior conductivity (~400 W/m·K), but heavier and pricier

- Hybrid Designs: Copper cold zones bonded to aluminum base for balanced performance

- Fluid Path and Sealing:

- Inlet/Outlet Ports: Positioned to ensure uniform flow distribution

- Gaskets or O-rings: EPDM, Viton, or fluorosilicone seals that resist selected coolants

- Manifold Design: Evenly splits flow to parallel channels, minimizing dead zones

Why Liquid Outperforms Air in High-Power Scenarios

“We saw a 40% temperature drop when switching from forced-air heat sinks to liquid cold plates in our power electronics racks,” reports an electrical engineer at a major EV manufacturer.

- Heat Transfer Coefficient (h):

- Liquid: 5,000–20,000 W/m²·K

- Air: 50–200 W/m²·K

- Compact Footprint: Liquid systems can be 50% smaller than equivalent air-cooled assemblies at the same thermal load

- Energy Efficiency: Pumps consume less energy than high-static-pressure fans, translating to lower operating costs

Real-World Applications

- Data Centers: Deploying cold plates on CPUs and GPUs reduces PUE by up to 10%.

- Electric Vehicles: Battery modules and inverter units leverage brazed cold plates to maintain optimal performance under rapid charge/discharge cycles.

- Telecom and 5G: High-power RF amplifiers benefit from uniform temperature control, extending component lifespan.

Key Takeaways:

- Liquid cold plates combine engineered channels and high-conductivity materials to extract heat far more effectively than air-cooling.

- Material and channel design choices directly impact thermal performance, weight, and cost.

- In demanding environments—like EV powertrains or AI servers—cold plates deliver compact, energy-efficient cooling that keeps you ahead of thermal limits.

Ready to explore custom liquid cold plate solutions? Kenfatech offers rapid prototyping, tailored channel designs, and full-scale manufacturing to meet your unique thermal challenges. Contact us to start your next project.

2. Which Types of Cooling Fluids Are Commonly Used?

Liquid cold plates commonly circulate three main fluid families: water-based mixtures (water with glycols and corrosion inhibitors), dielectric fluids (perfluorocarbons and synthetic esters), and specialty oils (mineral and synthetic). Water-based blends excel in thermal performance and cost, dielectric fluids provide electrical safety, and oils offer wide temperature stability. Selecting the right fluid balances heat transfer, materials compatibility, freeze protection, and maintenance needs to optimize reliability and efficiency in electronics cooling.

Let’s unpack the advantages, trade-offs, and real-world applications of each fluid category—and why choosing wisely makes all the difference.

Water-Based Mixtures: The Workhorse Coolants

- Composition:

- Base Fluid: Deionized or distilled water

- Additives:

- Ethylene or propylene glycol (10–50%) for freeze protection

- Corrosion inhibitors (silicates, phosphates) to protect metal channels

- Biocides to prevent microbial growth

“Switching to a 30% propylene glycol blend cut our freeze risk by 100% without noticeable thermal penalty,” says a thermal engineer at a leading datacenter operator.

| Property | Pure Water | 30% Glycol Blend |

|---|---|---|

| Specific Heat (J/kg·K) | 4,186 | ~3,800 |

| Thermal Conductivity (W/m·K) | 0.60 | ~0.45 |

| Freezing Point (°C) | 0 | –15 |

Pros:

- High thermal conductivity and capacity

- Low viscosity for minimal pump power

- Cost-effective and readily available

Cons:

- Electrical conductivity requires perfect sealing

- Corrosion risk without proper inhibitors

- Periodic monitoring and replacement needed

Dielectric Fluids: Safety-First Solutions

- Common Types: Fluorocarbon liquids (e.g., Fluorinert), Synthetic esters

- Key Benefit: Electrical insulation up to 30 kV/mm ensures no short circuits—even in leak scenarios.

Though dielectric fluids lag water in heat capacity, their immunity to electrical hazards and chemical stability under radiation make them invaluable in aerospace, telecom, and sensitive electronics.

Specialty Oils: Temperature-Stable Alternatives

Mineral and synthetic oils serve niche needs where extreme temperature swings or chemical inertness are required.

- Characteristics:

- High Boiling Points: >200 °C for safe operation in hot zones

- Low Pour Points: –40 °C or lower for subzero environments

Oils often require higher pumping energy and deliver lower heat capacity, but their stability pays off in mission-critical applications where downtime is unacceptable.

Comparison Table

| Fluid Type | Thermal Conductivity | Electrical Safety | Freeze Protection | Maintenance Frequency |

|---|---|---|---|---|

| Water-Based Mix | High | Low | Excellent (with glycols) | Quarterly analysis |

| Dielectric Fluid | Low | High | Moderate | Annual change-out |

| Mineral/Synthetic Oil | Moderate | Moderate | Low | Semi-annual flush |

Making the Choice: Selecting your coolant isn’t just a technical checkbox—it’s a strategic decision affecting longevity, energy costs, and system uptime. Consider:

- Application Sensitivity: Is electrical insulation a must?

- Climate Conditions: Do you need freeze protection?

- Maintenance Budget: How often can you flush and test?

Ready to optimize your system? Walmate Thermal offers expert fluid-selection consulting, full compatibility testing, and turnkey integration. Reach out today to tailor a coolant solution that powers your performance—with no compromises.

3. How Do Glycol–Water Mixtures Compare to Pure Water?

Glycol–water blends trade off some thermal performance for freeze protection and corrosion resistance. While pure water boasts a specific heat of 4,186 J/kg·K and thermal conductivity around 0.60 W/m·K, a typical 30% ethylene or propylene glycol mixture drops to ~3,800 J/kg·K and ~0.45 W/m·K respectively. Yet this modest loss is often justified: glycols depress freezing points to –15 °C or lower, inhibit rust in aluminum/copper channels, and extend maintenance intervals in cold-climate or outdoor applications.

Balancing performance against protection is at the heart of selecting a coolant. Let’s unpack the science, economics, and real-world lessons behind glycol–water systems.

1. Thermal Performance Metrics

- Specific Heat Capacity (Cp):

- Pure Water: 4,186 J/kg·K

- 30% Glycol Blend: ~3,800 J/kg·K (≈9% reduction)

Although the heat‐capacity loss seems small on paper, in large-scale systems—like data-center racks with 100 kW loads—that can translate to a 9 kW difference in heat storage per kilogram, impacting pump sizing and flow rates.

- Thermal Conductivity (k):

- Pure Water: 0.60 W/m·K

- 30% Glycol Blend: ≈0.45 W/m·K

| Blend Ratio | Freezing Point (°C) | Cp (J/kg·K) | k (W/m·K) |

|---|---|---|---|

| 0% Glycol | 0 | 4,186 | 0.60 |

| 20% Glycol | –8 | 4,000 | 0.50 |

| 30% Glycol | –15 | 3,800 | 0.45 |

| 50% Glycol | –35 | 3,400 | 0.35 |

2. Freeze Protection and System Reliability

- Depressed Freezing Point: “In our winter-field trials, a 40% propylene glycol coolant prevented ice formation even at –25 °C ambient,” reports a telecom engineer overseeing mountain-top base stations.

- Expansion Control: Glycol mixtures limit liquid expansion at subzero, reducing stress on microchannels and seals.

- Corrosion Inhibitors Synergy: Modern coolant kits combine glycols with silicate or phosphate inhibitors to keep aluminum and copper matrices pristine over years.

3. Viscosity and Pumping Power

- Viscosity Increase: Glycol addition raises fluid viscosity—at 30% glycol, viscosity at 20 °C increases by roughly 30% compared to water.

- Pump Energy Trade-off: Higher viscosity demands more pump head, but can be offset by slightly larger piping or high-efficiency centrifugal pumps.

Table: Viscosity vs. Temperature for 30% Propylene Glycol

Temperature (°C) Viscosity (cP) 0 40 20 7 40 3

4. Long-Term Maintenance and Lifecycle Cost

| Cost Component | Water Only | 30% Glycol Blend |

|---|---|---|

| Coolant Purchase | Low | Moderate |

| Pumping Energy (annual) | 1× | 1.1× |

| Fluid Change Frequency | 5 years | 2–3 years |

| Corrosion Repair Risk | Medium | Low |

5. Environmental and Safety Considerations

- Toxicity: Ethylene glycol is toxic; propylene glycol is food-grade safe but still requires proper disposal.

- Biodegradability: Modern propylene glycol formulas are more biodegradable, easing environmental compliance.

6. Case Study Snapshot

Automotive Inverter Cooling: A major EV OEM transitioned from pure water to a 25% propylene glycol blend. Results over a 12-month pilot: zero freeze incidents during winter tests, 15% reduction in unscheduled maintenance, and a marginal 3% bump in pump energy, offset by lower repair costs.

Key Takeaways:

- Glycol–water mixtures deliver vital freeze and corrosion protection with only modest thermal penalties.

- Optimal blend ratios depend on ambient conditions, channel materials, and maintenance budgets.

- Rigorous monitoring and scheduled fluid service extend system life and safeguard uptime.

Interested in a custom coolant analysis? Kenfatech offers in-house compatibility testing, inhibitor formulation, and field-trial support to ensure your liquid cold plate system runs flawlessly—no matter where you deploy it.

4. Are Dielectric Fluids Safe and Effective for Electronics Cooling?

Dielectric fluids—such as fluorocarbon liquids (e.g., 3M™ Fluorinert™) and synthetic esters—offer electrical insulation up to 30 kV/mm, making them inherently safe for direct immersion or leak-prone cold-plate systems. While their thermal conductivity (0.06–0.12 W/m·K) and specific heat (1,000–1,500 J/kg·K) lag behind water, they eliminate short-circuit risk and simplify system design. For high-value or sensitive electronics, dielectric coolants provide peace of mind and reliable thermal performance without compromising safety.

In markets where electrical reliability is non-negotiable—telecom, aerospace, high-voltage inverters—the unique properties of dielectric fluids can outweigh their lower heat-transfer metrics. Let’s unpack why and when they excel.

1. Electrical Insulation: The Ultimate Safeguard

| Fluid Type | Dielectric Strength (kV/mm) |

|---|---|

| Perfluorocarbon (PFC) | 25–30 |

| Synthetic Ester | 15–20 |

| Water-Based Mixtures | 0 |

With electrical breakdown voltages exceeding 15 kV/mm, dielectric fluids prevent arcing and short circuits—even if a leak occurs or internal channels develop hairline cracks. This capability is critical in high-voltage power electronics and immersion cooling of entire circuit boards.

2. Thermal Performance Trade-offs

- Thermal Conductivity (k): PFCs: ≈0.06–0.08 W/m·K; Esters: ≈0.10–0.12 W/m·K

- Specific Heat (Cp): PFCs: ≈1,100 J/kg·K; Esters: ≈1,300–1,500 J/kg·K

Compared to a water–glycol blend, dielectric fluids transfer heat at 15–25% the rate. Yet in small-channel microfluidic plates—where path lengths are minimal—this can be mitigated by higher flow rates and optimized channel geometry.

3. Chemical Stability and Longevity

- Inertness: PFCs resist oxidation and maintain properties under radiation or UV exposure.

- Viscosity Stability: Synthetic esters show minimal viscosity change from –40 °C to 100 °C.

Case Study: A satellite avionics provider selected a fluorocarbon coolant for 5-year missions. The fluid’s unmatched chemical stability meant zero degradation, preserving both thermal performance and electronic integrity in space.

4. Environmental and Cost Considerations

| Factor | Fluorocarbons | Synthetic Esters |

|---|---|---|

| Global Warming Potential | Very High | Low–Moderate |

| Biodegradability | No | Limited |

| Unit Cost (per liter) | $80–$120 | $20–$40 |

| Disposal Expense | Significant | Moderate |

5. System Design Implications

- Pump Selection: Higher flow rates can offset low thermal conductivity; choose pumps rated for non-aqueous fluids.

- Sealing Materials: Use compatible seals (e.g., Kalrez®, EPDM) to prevent fluid swell or degradation.

- Leak Detection: Optical or flow-based sensors ensure immediate response.

6. Balancing Effectiveness with Practicality

Although dielectric fluids carry a thermal performance penalty, they simplify safety certifications and can reduce system complexity by removing the need for stringent electrical isolation barriers. In high-stakes environments, the trade-off favors reliability over raw heat-transfer numbers.

Key Takeaways:

- Dielectric fluids bring unparalleled electrical safety.

- Their lower thermal metrics can be mitigated through channel design and flow optimization.

- Synthetic esters provide a greener alternative to perfluorocarbons.

Considering dielectric cooling for your next project? Walmate Thermal offers end-to-end design services, pump selection expertise, and environmental impact assessments to help you implement the safest, most effective coolant solution. Contact us today!

5. Do Mineral and Synthetic Oils Offer Unique Benefits?

Mineral and synthetic oils provide extended temperature stability, excellent chemical inertness, and low vapor pressure—key for applications with extreme heat or vacuum conditions. Though their specific heat (1,800–2,200 J/kg·K) and thermal conductivity (0.12–0.18 W/m·K) lag water-based coolants, oils excel where equipment must survive wide thermal swings, aggressive chemistries, or pressurized environments without oxidation or degradation.

Let’s examine how these oils carve out niche roles in cooling systems and what designers must weigh before specifying them.

1. Thermal and Physical Properties

| Property | Mineral Oil | Synthetic Oil |

|---|---|---|

| Specific Heat (J/kg·K) | 1,800–2,000 | 2,000–2,200 |

| Thermal Conductivity (W/m·K) | 0.12–0.15 | 0.15–0.18 |

| Viscosity (cP @ 25 °C) | 20–50 | 10–30 |

| Boiling Point (°C) | 200–260 | 260–320 |

| Pour Point (°C) | –20 to –10 | –40 to –20 |

2. Chemical Compatibility and Stability

- Oxidation Resistance: Synthetic oils resist oxidative breakdown at high temperatures, extending fluid life.

- Inertness: Neither oil reacts with metals, plastics, or seal materials, avoiding corrosion and swelling.

- Low Vapor Pressure: Prevents cavitation in pumps and reduces vapor-lock risk.

Case Example: A telecom vendor deployed silicone-based oil in tower-mounted amplifiers. Despite ambient swings from –30 °C to 60 °C, the oil exhibited negligible viscosity variation, ensuring uninterrupted cooling.

3. Pumping and Flow Considerations

- Higher Viscosity: Oils require pumps capable of higher head pressure—often gear or progressive cavity pumps.

- Flow Rate Adjustments: A 20% reduction in volumetric flow can occur if switching from water to oil, necessitating channel redesign or larger tubing.

4. Maintenance and Lifecycle

| Aspect | Mineral Oil | Synthetic Oil |

|---|---|---|

| Recommended Change-Out | 1–2 years | 3–5 years |

| Filter Requirements | Fine filtration | Similar or coarser filters |

| Monitoring Parameters | Viscosity, acidity | Viscosity, dielectric constant |

5. Application Niches

- Vacuum Environments: Oils’ low vapor pressure prevents chamber contamination.

- High-Voltage Switchgear: Oil provides both cooling and insulation in transformer designs.

- Extreme Ambient Conditions: Outdoor processes with large temperature swings rely on oil’s broad fluidity range.

Client Spotlight: An energy-storage integrator adopted polyalphaolefin oil for inverter cooling across desert installations. Despite 50 °C midday heat, no pump cavitation or seal failures occurred over two years.

Trade-Off Summary:

- Pros: Wide temperature range, chemical inertness, low maintenance frequency

- Cons: Lower thermal performance vs. water, higher pump energy, specialized equipment

Whether you’re tackling subzero telecommunication sites or high-voltage transformer banks, Kenfatech can recommend the optimal oil type, configure your loop components, and validate system performance—ensuring your electronic assets stay cool under any condition.

6. What Criteria Should Be Considered When Selecting a Cooling Fluid?

Choosing the right coolant hinges on balancing thermal efficiency (conductivity, specific heat), electrical safety (insulation vs. conductivity), freeze/boil protection, viscosity and pumping power, chemical compatibility with materials, environmental impact, and maintenance regimen. By prioritizing which factors matter most—such as maximum ΔT, ambient extremes, or regulatory compliance—you can tailor a fluid selection that maximizes longevity, minimizes energy use, and safeguards sensitive electronics.

Let’s break down each key criterion and explore how it shapes your cooling system’s performance, reliability, and total cost of ownership.

1. Thermal Performance

- Thermal Conductivity (k): Higher k delivers faster heat removal—critical for high-density chips.

- Specific Heat (Cp): Fluids with high Cp absorb more energy per mass flow, reducing required flow rates.

- Heat Transfer Coefficient (h): Dependent on fluid properties and channel design; governs ΔT between plate and fluid.

Tip: Plot k and Cp vs. temperature for candidate fluids to visualize performance across your operating range.

2. Electrical Properties

| Property | Requirement |

|---|---|

| Electrical Conductivity | Low for water-based; negligible for dielectrics |

| Dielectric Strength | ≥ required system voltage margin |

| Breakdown Voltage | Safety buffer to prevent arcing |

Air/glycol mixtures are conductive and require perfect sealing, whereas dielectric fluids allow direct immersion—ideal for high-voltage or leak-sensitive environments.

3. Freeze & Boil Protection

| Fluid Type | Freeze Pt (°C) | Boil Pt (°C) |

|---|---|---|

| Pure Water | 0 | 100 |

| 30% Glycol Blend | –15 | 107 |

| Dielectric Ester | –40 | 200+ |

| Silicone Oil | –50 | 300+ |

4. Viscosity & Pumping Requirements

- Viscosity (μ): Directly influences pump head and energy consumption.

- Temperature Dependence: Fluids whose viscosity changes sharply can cause uneven cooling zones.

Design Note: A 25% glycol blend at 0 °C can be 5× more viscous than at 25 °C—plan for worst-case pumping scenarios.

5. Chemical Compatibility & Corrosion

- Ensure fluid doesn’t degrade seals (EPDM, Viton), gaskets, or metal channel walls.

- Use corrosion inhibitors and monitor pH over time.

- Integrate biocides to prevent biofilm that clogs microchannels.

6. Environmental, Health & Safety (EHS)

- Toxicity & Disposal: Understand regulations for glycols, dielectrics, and oils.

- Global Warming Potential: PFCs are high-GWP; esters and glycols have lower footprints.

- Regulatory Compliance: ROHS, REACH, and local disposal rules can restrict fluid choices.

7. Maintenance & Lifecycle Cost

- Fluids with longer stability reduce downtime and labor costs.

- Monitoring needs: corrosion probes, particle counters, periodic chemical analysis.

- Balance upfront fluid & equipment costs against energy use and service frequency.

Checklist:

- Define your operating temperature extremes

- Quantify acceptable maintenance cadence

- Audit materials in contact with fluid

- Evaluate environmental and safety constraints

Kenfatech can guide you through this decision matrix, offering fluid compatibility testing, custom inhibitor formulations, and real-world pilot trials to ensure your system runs optimally from day one. Contact us to start the conversation.

7. How Can Fluid Compatibility Impact Reliability and Maintenance?

Fluid compatibility affects system longevity, performance, and upkeep costs. Incompatible coolants can corrode channels, swell or degrade seals, and promote microbial growth—leading to leaks, pressure drops, and reduced heat transfer. Conversely, a well-matched coolant preserves materials, minimizes downtime, and simplifies maintenance schedules by resisting corrosion and fouling. A proactive compatibility assessment and regular fluid analysis are essential to ensuring your liquid cold plate system remains reliable and efficient over its entire service life.

Understanding the interplay between coolant chemistry and system materials is crucial—let’s explore the nuances and best practices to keep your cold-plate solution running smoothly.

1. Corrosion and Erosion Risks

- Aluminum–copper assemblies often develop galvanic corrosion if coolant pH drifts outside 8–10.

- Particulate ingress can abrade microchannel walls, reducing thermal contact and causing pressure losses.

Case in Point: A data-center operator saw a 12% drop in coolant flow after six months because degraded O-rings shed particles that clogged microchannels.

2. Seal and Gasket Degradation

| Seal Material | Compatibility Notes | Maintenance Tip |

|---|---|---|

| EPDM | Good with glycols; avoid high-ester concentrations | Inspect monthly for hardness changes |

| Viton® | Excellent with oils and esters; moderate with glycols | Replace every 2–3 years regardless of appearance |

| Silicone | Universal resistance; lower compression set | Check torque on flanges quarterly |

3. Microbial Growth and Fouling

- Water-based coolants without adequate biocides can host biofilms that reduce heat transfer and flow.

- Organic breakdown of glycols yields sludge, feeding further microbial growth.

Pro Tip: Integrate UV sterilization loops or periodic thermal shock cycles (heating to 60 °C for 2 hours) to disrupt biofilms without removing your plates.

4. Monitoring and Preventive Maintenance

- Quarterly tests for pH, inhibitor concentration, and glycol degradation products keep corrosion in check.

- Inline particle counters reveal early signs of erosion or gasket failure—aim for ISO 14/13/11 cleanliness in microchannel systems.

- Infrared thermal imaging can spot hotspots caused by fouling for targeted cleaning before full-system performance degrades.

5. Material Compatibility Protocol

- Build a compatibility matrix cross-referencing fluid additives vs. component materials.

- Conduct accelerated aging tests at elevated temperatures to simulate years of operation.

- Pilot a small loop under representative conditions, monitoring flow, temperature, and chemistry for at least three months.

6. Total Cost of Ownership (TCO) Implications

| Factor | Compatible System | Incompatible System |

|---|---|---|

| Maintenance Frequency | Annual | Quarterly |

| Unplanned Downtime | <0.5% | 3–5% per year |

| Repair & Replacement Costs | Low | High |

| Energy Efficiency Degradation | <2% over 5 years | 10–15% over 2 years |

By rigorously evaluating fluid compatibility and establishing proactive maintenance protocols, you can safeguard your liquid cold plate system against the silent threats of corrosion, fouling, and seal failure. Kenfatech’s in-house labs, compatibility matrices, and field-tested maintenance programs ensure your cooling solution remains robust and low-maintenance—so you can focus on your core electronics innovations.

Conclusion

Navigating the complex landscape of liquid cold plate coolants is a critical step toward maximizing performance, reliability, and total cost of ownership in high-density electronics applications. From water-based glycol mixtures—which deliver unmatched thermal conductivity and freeze protection—to dielectric fluids that ensure electrical safety even under leak-prone conditions, and specialty oils engineered for extreme temperature ranges, each fluid family brings unique advantages and trade-offs. By carefully weighing thermal performance, electrical properties, freeze/boil points, viscosity, chemical compatibility, and environmental considerations, you can tailor a cooling solution that precisely meets your system’s demands.

Key takeaways:

- Water-glycol blends offer the best balance of heat capacity and cost, with additives to prevent corrosion and microbial growth.

- Dielectric coolants enable direct-contact cooling of sensitive electronics without risk of short circuits—ideal for high-voltage or immersion systems.

- Mineral and synthetic oils excel in harsh environments where broad temperature stability and chemical inertness are non-negotiable.

- A rigorous compatibility assessment, proactive monitoring, and scheduled maintenance are essential to prevent corrosion, fouling, and seal failures.

Whether you’re designing data center racks, EV inverters, telecom amplifiers, or aerospace avionics, the right fluid choice can mean the difference between peak efficiency and costly downtime. At Walmate Thermal, we specialize in custom cold-plate design and fluid selection—backed by in-house testing labs, field-proven compatibility protocols, and turnkey integration services.

Contact our engineering team today to discuss your unique cooling challenges and receive a tailored quotation for your liquid cold plate solution. We look forward to partnering with you to keep your electronics running cool, efficient, and reliable.