Customized thermal solution design based on Ansys 22.0

Focusing on professional expertise in the fields of heat sinks and liquid cold plates. We delve into technical precision to ensure every simulation analysis seamlessly matches clients' thermal management needs. By integrating profound industry experience with Ansys' powerful capabilities, our services deliver tangible value for heat sink and liquid cold plate designs, bridging design goals with practical outcomes and making professionalism the core cornerstone of tailored thermal engineering support.

Customized thermal solution design based on Ansys 22.0

Focusing on professional expertise in the fields of heat sinks and Liquid cooling plates. We delve into technical precision to ensure every simulation analysis seamlessly matches clients’ thermal management needs. By integrating profound industry experience with Ansys’ powerful capabilities, our services deliver tangible value for heat sink and liquid cold plate designs, bridging design goals with practical outcomes and making professionalism the core cornerstone of tailored thermal engineering support. Based on the different power requirements of customers, produce thermal pads of different thicknesses for filling the gaps between heat sink components and chips to increase the overall heat transfer capacity of the system. The unique combination of thermal conductivity and flexibility reduces mechanical stress while maintaining thermal performance. Walmate Thermal has a wide range of gap pad product lines, including various properties, ultra-thin gap fillers, high deflection series, and materials that provide electrical isolation.

Partner with us, and we can provide thermal design services to solve clients' traditional design challenges.

* Conventional thermal solution development faces high prototyping costs and long cycles.

* Overheating issues in products lead to performance degradation or even failurewhile.

* It is difficult to accurately predict thermal performance under complex operating conditions.

* Leveraging Ansys’ powerful simulation capabilities, we conduct advance simulation, optimization, and validation to reduce the number of physical tests.

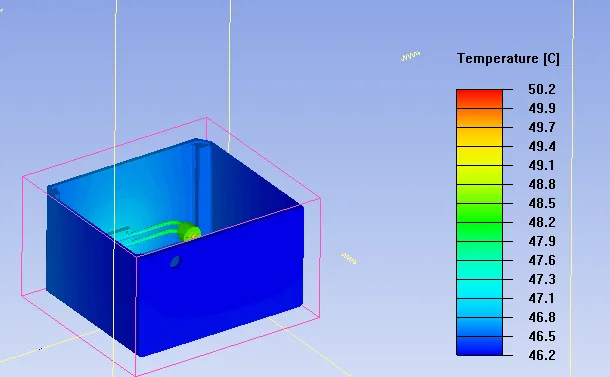

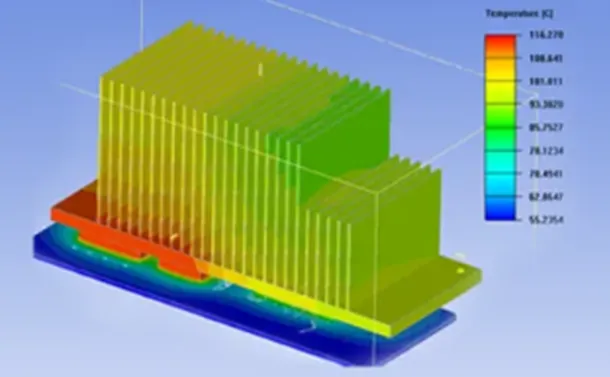

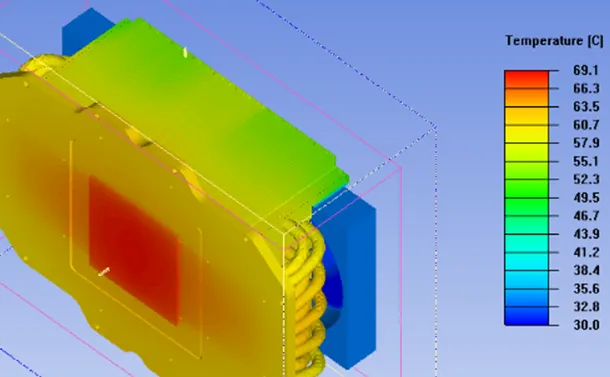

Customized heat sink thermal solution

Our customized thermal design services for heat sinks begin with understanding clients’ product parameters, including power, dimensions, and operating conditions. We then conduct full-process simulations of conduction, convection, and radiation to lay a solid foundation. Focusing on precision, we optimize heat sink fin dimensions—meticulously adjusting height, spacing, thickness, and length. We also perform in-depth analysis of different materials to evaluate their thermal performance. These tailored efforts ensure we design heat sinks that perfectly meet clients’ specific cooling goals and performance requirements. in proportion, and finally forming them into sheets or substances with different viscosities under high pressure. This substance is typically used to fill the connection between electronic components and heat sinks, thereby reducing the gaps formed between the heat sink and the components, which would otherwise create significant thermal resistance. When filled with this interface material, a large amount of heat can be conducted to the heat sink, thus lowering the temperature of the entire chip.

Our technical strength lies in our professional team and rigorous processes

Our Core engineers all have 5-8 years of working experience in Fortune 500 companies, among whom senior design leaders boast over 10 years of industry experience, with the entire team holding professional Ansys certification qualifications.In the technical implementation phase, we not only use Ansys for auxiliary design but also conduct sample verification with equipment such as thermal imagers and flow meters. By combining actual product performance with simulated analysis data, we accurately identify discrepancies. For instance, in heat pipe design, we derive precise results that are infinitely close to real values by comparing industry empirical parameters with measured data.We specialize in heat sink and liquid cold plate design, with deep expertise in both product design and manufacturing processes. This ensures our solutions balance performance and manufacturability, boasting strong implementability—which is our core advantage over competitors.

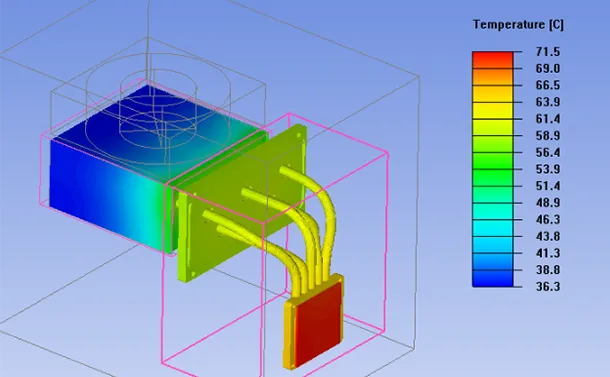

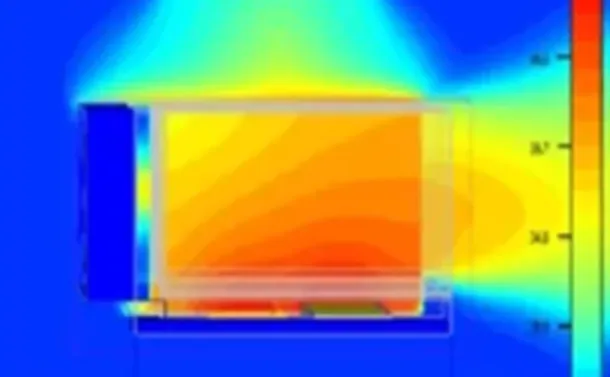

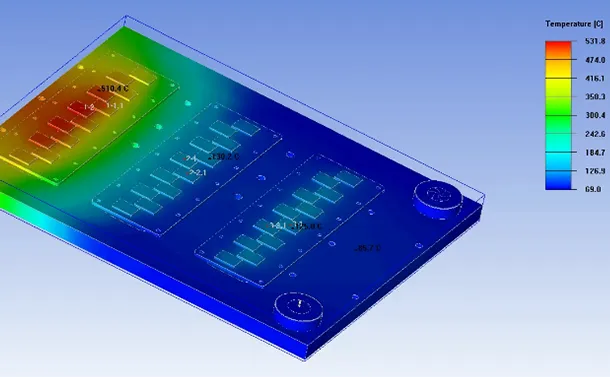

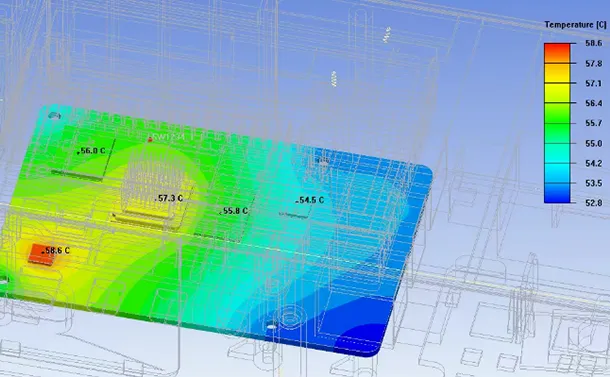

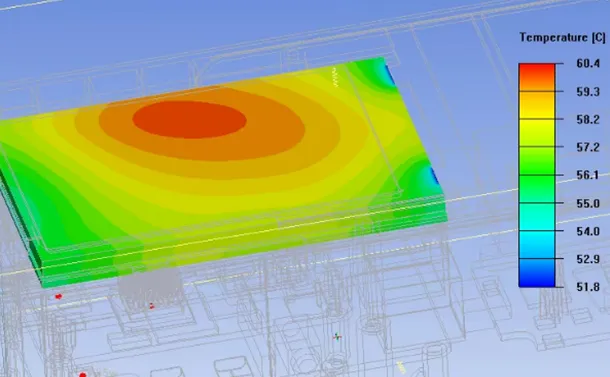

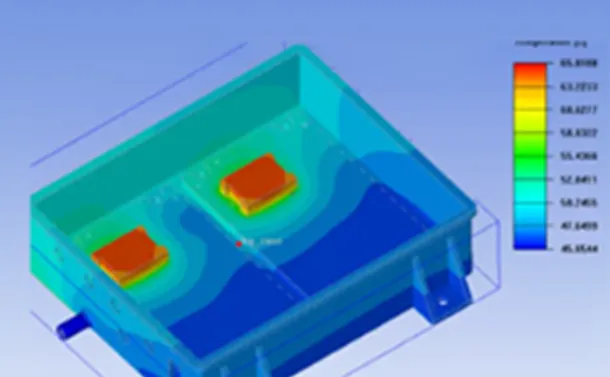

Customized Liquid cooling plate thermal solutions

Our customized thermal design services for heat sinks begin with understanding clients’ product parameters, including power, dimensions, and operating conditions. We then conduct full-process simulations of conduction, convection, and radiation to lay a solid foundation. Focusing on precision, we optimize heat sink fin dimensions—meticulously adjusting height, spacing, thickness, and length. We also perform in-depth analysis of different materials to evaluate their thermal performance. These tailored efforts ensure we design heat sinks that perfectly meet clients’ specific cooling goals and performance requirements.

1,How to do a heat sink thermal solution?

2, How to do a liquid cooling plate thermal soultion?