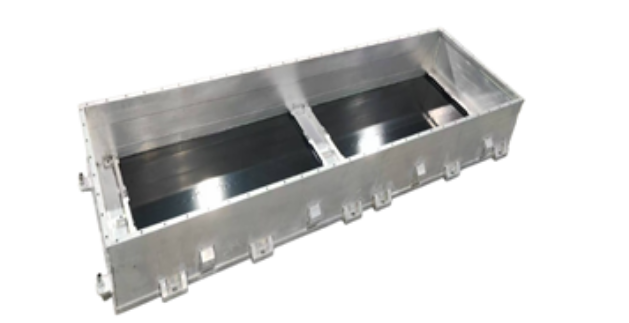

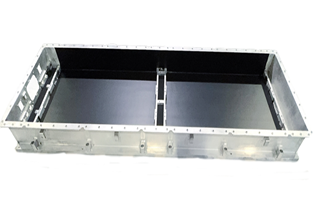

Product name: Battery liquid cooling plate

Size1: 840x251x2260mm

Size2: 730x229x2220mm

With the rapid development of new energy vehicles, especially large trucks, heavy-duty trucks, and mining trucks, energy demand is growing increasingly. Stacking a certain number of battery modules can thus provide power for these trucks. In many mining sites, for instance, 20-ton empty trucks traveling from the foot to the top of the mountain consume relatively little energy, which can be supplied by either fuel or electricity. However, when these trucks are fully loaded with heavy cargo and descend from the mountain, the height difference and gravitational force enable them to generate more electricity during operation—requiring multi-module battery setups to store this energy.

Our stacked liquid cooling plates are designed to meet customers’ needs for series or parallel configurations of different battery modules. We offer customizable stacking options, including 1-layer, 2-layer, or even 3-layer setups, to maximize energy storage capacity for vehicles. This allows trucks to recharge their batteries to approximately 85% capacity during descent. When returning to the mountain top, the stored electricity can power the ascent, creating a repeating cycle that continues until evening, when the batteries can be fully recharged. This approach is increasingly adopted across industries, particularly for large trucks, ships, and other heavy-duty equipment requiring a steady energy supply—all of which rely on such stacked battery modules.

For large-scale stacked battery systems, effective thermal management is critical to prevent heat-related performance issues. Our liquid cooling plates address this through a reliable design: flow channels are precision-manufactured using profile extrusion, and argon arc welding is employed to form a series-connected structure, ensuring both structural integrity and performance stability. We also provide custom design and production services tailored to customers’ specific size requirements.

Currently, our annual production capacity ranges from 100,000 to 200,000 units. Once our new factory is completed, we plan to expand annual output to 500,000 to 800,000 units.

If you have any needs, you can send us an email, and Walmate thermal can provide you with our current production drawings for reference. You can use 3D models to assemble your structural designs. I believe this is something every structural engineer would highly appreciate. This is also the first step in our willingness to collaborate with you and become partners.