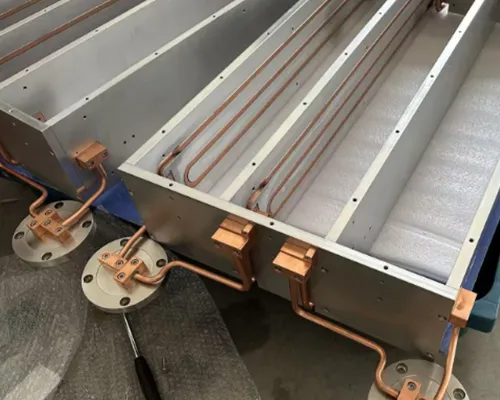

Round tube Liquid cold plates

By embedding the round tube into the plate, a liquid circulation channel is formed, which utilizes the flow of liquid to remove heat and achieve efficient heat dissipation. Based on the principles of heat conduction and convection, heat is transferred from the heat source to the liquid cooled plate, and then carried away by the flowing liquid

Get a Quotation

What is a round embedded liquid cold plate?

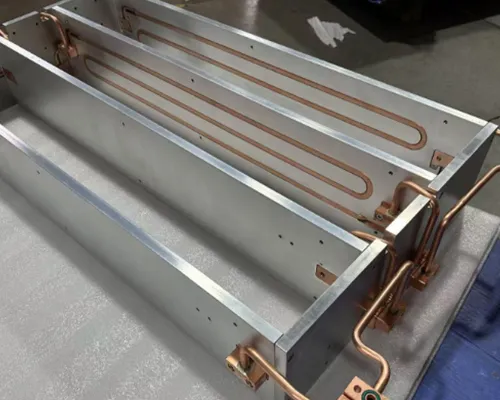

The round tube embedded liquid cooling plate is a kind of high-efficiency heat dissipation device. Its structural design involves embedding round aluminum tubes or stainless steel tubes into plate materials such as aluminum plates and copper plates to form a flow channel for the coolant circulation. During operation, the coolant circulates and flows inside the tubes. Through heat conduction, the heat from the heat sources in contact with the plate body is transferred into the tubes. Then, by means of convective heat transfer through the flow of the coolant, the heat is carried away. In this way, it achieves efficient heat dissipation for the heating components and ensures the stable operation of the equipment.

Characteristics of embedded cold plate in round tube

Exquisite structural design

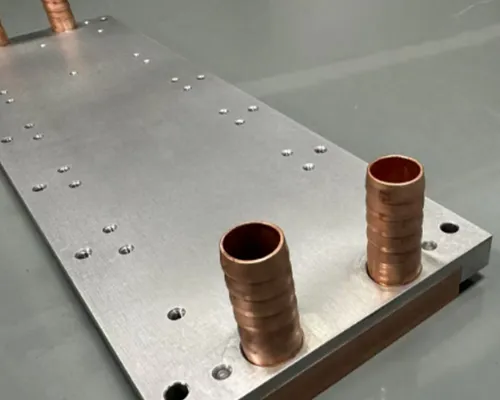

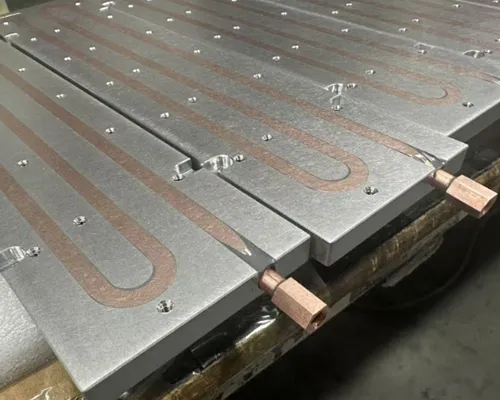

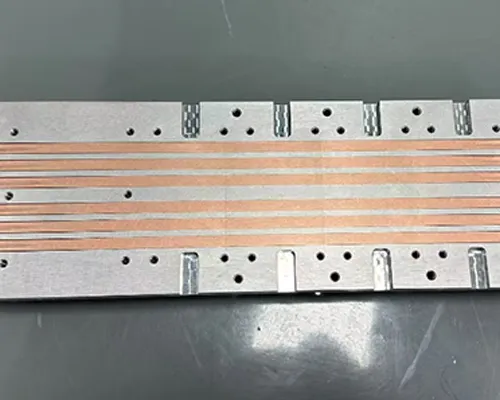

It is mainly composed of a round tube and an aluminum plate. Semi-circular grooves are pre-cut on the aluminum plate for embedding the round tube. The gaps between the grooves and the round tube can be filled with high thermal conductivity epoxy resin or filled by soldering with solder paste to ensure a close fit between the two and guarantee the heat conduction efficiency.

Simple production process

There is no need for complex molds. Simply embedding the ready-made aluminum tube or copper tube into the aluminum plate can complete the production, which greatly reduces the production difficulty and cost, and the production process is simple and efficient.

Excellent sealing performance

The round tube has a closed tube body structure. Compared with other liquid cooling forms, the risk of liquid leakage is almost zero, the operation reliability is high, and the maintenance cost is low.

Strong space adaptability

With the embedded structure of the round tube, it can be flexibly placed and bent within a limited space, meeting the diverse installation requirements, especially suitable for application scenarios with strict requirements for space layout.

How does Walmate make a tube embedded liquid cold plate?

Manufacturing the round tube embedded liquid cooling plate, we will accurately determine the specifications of the round tube according to the customer’s requirements. For the flow channel, the round tube usually selects copper tubes with a diameter of 6.35 mm or 9.52 mm to meet different heat dissipation needs. Taking into account the requirements of subsequent CNC processing technology and the pressure-bearing performance of the flow channel, the wall thickness of the round tube is controlled at 1.0 – 1.2 mm. This design enables the flow channel to maintain structural stability and not be easily deformed under the pressure condition of 1.5 – 2 MPa. At the same time, it also ensures that the round tube will not crack during the CNC processing, effectively guaranteeing the processing quality and service reliability of the liquid cooling plate.

When processing the bottom plate of the liquid cooling plate, we adopt a special groove design with patented technology. After the round tube is pressed into these grooves, it can achieve a tight fit with the bottom plate, enabling the heat to be rapidly transferred to the coolant inside the round tube. Subsequently, the heat is effectively carried away through the circulation of the coolant. In addition, to ensure that the gaps between the grooves and the round tube are completely filled, we will fill the grooves with epoxy resin or solder paste to further improve the heat conduction efficiency.

What can we do the round embedded cold plate for our clients?

Design and Customization Services

We are capable of designing and manufacturing embedded round – tube cold plates for customers. Firstly, we offer thermal design and analysis services. Customers only need to inform us of the required power, coolant flow rate, and the size of the cold plate, and we can carry out customized designs. Secondly, in terms of round – tube selection, with our rich experience, we can make appropriate choices for customers based on a variety of materials, helping them save costs and improve efficiency.

Quality Assurance and Coolant Recommendations

For the production of cold plates, we have a set of standard quality processes for surface treatment, which effectively prevents oxidation and corrosion of the cold plates. In addition, we can also recommend suitable coolants and their specifications to customers according to different conditions, enabling them to have anti – corrosion and anti – freezing functions while maximizing heat dissipation efficiency.