LED Lighting thermal management

LEDs generate a large amount of heat during operation. When the temperature is too high, it can lead to increased light attenuation, decreased luminous efficiency, and seriously affect the lighting effect and service life.

Our Businesses

Get a Quotation

What is a LED heat sink?

LED lighting heat sink is a device used to dissipate the heat generated by LED lighting fixtures. LEDs generate a large amount of heat during operation. If this heat is not dissipated in a timely manner, it can cause the temperature of the LED chip to rise, thereby affecting its luminous efficiency, color stability, and service life. LED lighting heat sinks are usually made of materials with high thermal conductivity, such as aluminum, copper, etc. By increasing the heat dissipation area and promoting air convection, the heat generated by LED chips is quickly transferred to the surrounding environment to ensure that LED lamps work within the appropriate temperature range, thereby improving the performance and reliability of the lamps and extending their service life.

How to design a LED heat sink?

Heat dissipation method

When designing a high-power LED heat sink, the first step is to determine whether it is natural heat dissipation or forced convection heat dissipation, which will fundamentally determine the design direction and performance of the heat sink.

Natural heat dissipation

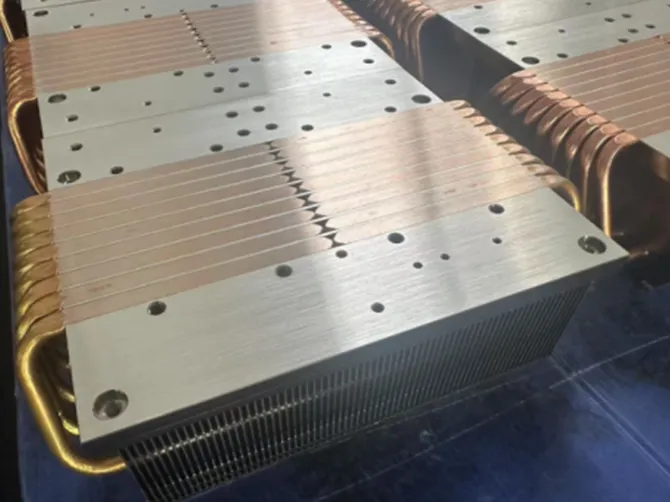

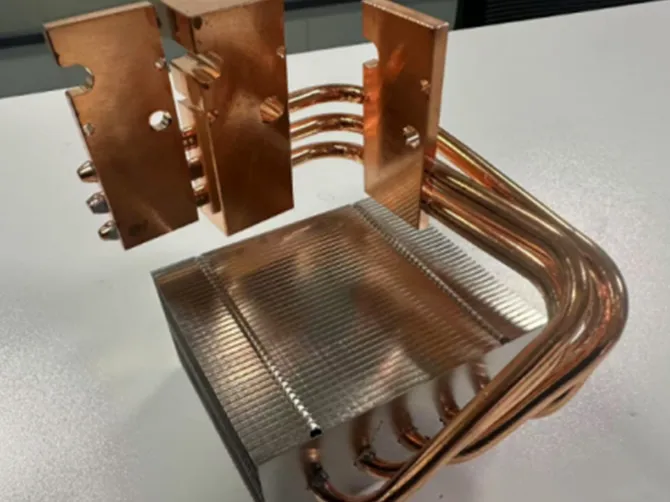

It relies on natural convection, thermal radiation, and the thermal conductivity of the material itself to dissipate heat. In order to achieve efficient natural heat dissipation, materials with high thermal conductivity, such as copper or aluminum alloys, need to be selected. At the same time, it is necessary to increase the heat dissipation area by optimizing the radiator structure. Generally, Die-casting process or Cold forging processes are used, and multi fin designs are adopted. The spacing and shape of fins are reasonably planned, such as using wavy or serrated fins, to enhance the natural convection effect of air. The surface of the radiator can also be treated to increase its emissivity and enhance radiative heat dissipation.

Forced convection heat dissipation

It mainly uses devices such as fans to force air flow and accelerate heat transfer. In design, the selection of fans is key. Choose a fan with appropriate air volume and pressure based on the size of the radiator, required heat dissipation, and allowable noise range. At the same time, it is necessary to optimize the design of the air duct to ensure that air can flow evenly and efficiently through the surface of the radiator, reducing ineffective air resistance and hot air backflow. The structural design of the radiator is equally important, and it should be coordinated with the fan to guide the airflow and fully utilize the heat dissipation advantages of forced convection.

Walmate thermal design capability

We have industry-leading thermal design capabilities and provide comprehensive and efficient solutions for high-power LED heat dissipation.

Accurate demand assessment: With the help of professional equipment and rich experience, accurately calculate the power of LED lamps and determine the heat dissipation requirements based on actual working conditions.

Diversified heat dissipation methods: In the natural heat dissipation scheme, high thermal conductivity materials such as copper and aluminum alloys are selected, and a multi fin structure is carefully designed to optimize the shape and spacing of fins and enhance the natural convection heat dissipation effect; Forced convection heat dissipation will be based on the space and heat dissipation requirements of the lighting fixtures, accurately matched with axial or centrifugal fans, and equipped with scientific air duct design to achieve efficient air circulation and improve heat dissipation efficiency.

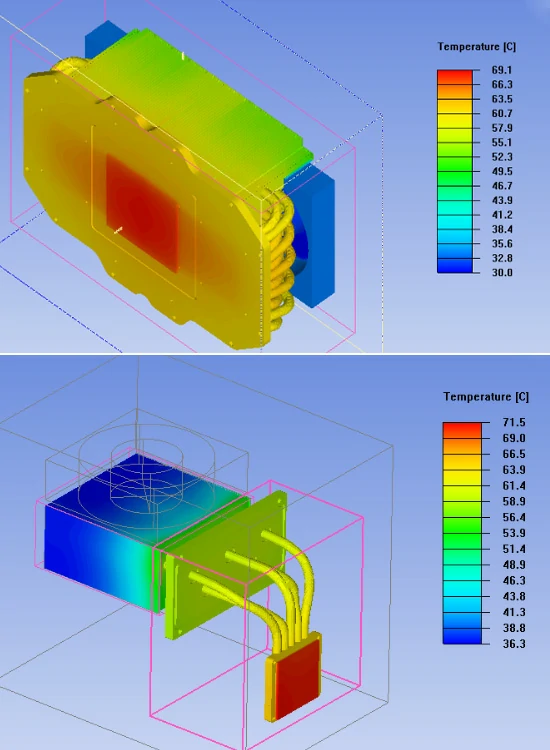

Innovative structural design: Advanced thermal simulation software ANSYS is used to simulate and analyze the radiator structure. Innovatively designing a composite structure combining heat pipes and uniform heat plates to quickly and evenly disperse heat and solve local overheating problems; We have also developed an intelligent temperature control adjustable heat dissipation structure, which automatically adjusts the heat dissipation power based on the LED temperature.