Battery cell cooling

A professional manufacturer of battery module thermal management, unlocking the overheating problem of battery modules, and customized aluminum liquid cooling plates to ensure the temperature operation of battery cells

Our Businesses

Get a Quotation

Battery moudles thermal managment:

Walmate Thermal focuses on the field of battery cells thermal management, providing customized and efficient thermal management solutions for various battery application scenarios with profound technical accumulation and rich practical experience. Whether it's electric vehicles, energy storage stations, or other devices that use batteries, we can ensure that the batteries operate within the ideal temperature range through advanced aluminum liquid cooled plates and other products, improving battery performance, safety, and service life. Whether it's the series and parallel connection methods or size requirements of your different battery cells, we can ask you for customized design and production. Of course, we also have existing standard products to provide you with choices, which can save R&D time, tooling costs, and product unit prices.

What is a liquid cold plate for battery cells:

The liquid cold plate of battery cells is a key component used for battery thermal management, usually made of materials with good thermal conductivity such as aluminum alloy. Its function is to remove the heat generated by the battery cells through the circulation of coolant during the charging and discharging process, keeping the cells within a suitable working temperature range to improve the performance, safety, and service life of the battery.

Liquid cooled plates generally have a flow channel design, in which the coolant flows and can fully contact and exchange heat with the battery cells. According to different application scenarios and battery types, liquid cooled plates have various structural forms, such as serpentine channel liquid cooled plates, microchannel liquid cooled plates, and double-sided liquid cooled plates

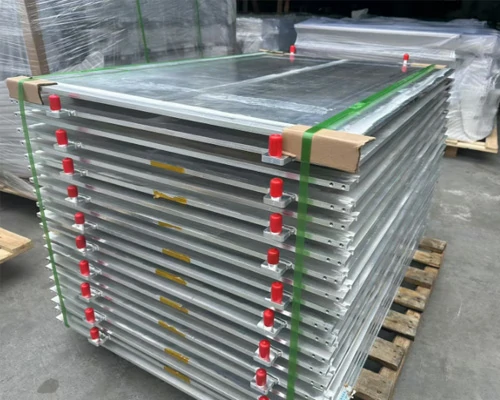

Walmate thermal battery cells cooling production:

Aluminum liquid cooled plate:

Efficient Heat Dissipation: Our liquid cooling plate represents the pinnacle of thermal management technology. Crafted from premium-grade aluminum with a staggering purity of 99.9%, it capitalizes on aluminum’s remarkable thermal conductivity, ensuring rapid heat transfer and superior heat dissipation. The meticulously engineered internal flow channel design isn’t just a feature—it’s a game-changer. By facilitating an even distribution of the coolant throughout the system, it maximizes contact with heat sources, thereby significantly enhancing heat dissipation efficiency.

In stark contrast to conventional heat dissipation approaches, this advanced solution can reduce battery temperatures by an impressive 15℃ to 25℃. This substantial cooling effect isn’t just about lowering temperatures; it’s about maintaining optimal operational conditions. By keeping the temperature consistency deviation within the battery pack to an absolute minimum, it safeguards battery performance, extends lifespan, and ultimately boosts overall system reliability.

Customized design: Personalized liquid cooling plate design based on the shape, size, and heat dissipation requirements of different battery packs. Whether it’s irregular battery arrangements or applications with strict space requirements, we can provide perfectly adapted solutions to achieve efficient heat exchange and compact layout.◦ Reliable and durable: After rigorous pressure resistance, corrosion resistance, and fatigue testing, the liquid cooled plate ensures stable operation under various complex working conditions. The advanced copper brazing process tightly connects the various components of the liquid cooled plate, effectively preventing coolant leakage, enhancing the structural strength of the product, extending its service life, and providing customers with reliable long-term protection.

Technical advantages

R&D team: We have a professional R&D team composed of senior thermal management experts, material scientists, and engineers, with profound technical expertise and rich industry experience. Team members continuously explore and apply cutting-edge technologies, committed to providing customers with the most advanced and reliable thermal management solutions.

Testing and Verification: A comprehensive testing and verification system has been established, which rigorously tests the performance and reliability of products such as aluminum liquid cooled plates by simulating various extreme working conditions and actual usage scenarios. Each product has undergone multiple optimizations and improvements to ensure that it meets the highest quality standards before being delivered to customers.

Battery cell liquid cold plate standard parts

Walmate thermal excels in producing battery pack liquid cold plates . To streamline the selection process for customers, we’ve pre – developed molds for a wide array of standard products. Whether for automotive, energy storage, or industrial applications, these products come in multiple sizes, shapes, and performance levels. They undergo strict quality checks, enabling clients to quickly source ideal cooling solutions.

| MFG Part# | cell capacity (Ah) | Cell quantity | Length(mm) | Width(mm) | Height (mm) | Inlet /outlet external diameter(mm) |

| MT2408037 | 314 | 36S | 1125 | 630 | 12 | 14 |

| 5-07-01445 | 314 | 48S | 1033 | 776 | 10 | 14 |

| 5-07-01612 | 314 | 52S | 1138 | 790 | 10 | 14 |

| 5-08-01487 | 314 | 52S | 1163.3 | 810 | 41 | 14 |

| 5-07-01540 | 314 | 104S | 2192.5 | 790 | 41 | 18 |

| 5-07-01573 | 314 | 52S | 1220 | 810 | 265 | 18 |

| 5-07-01592 | 304 | 36S | 1084 | 622 | 120 | 16 |

| 5-07-01593 | 304 | 36S | 939 | 622 | 120 | 16 |